Single-groove double-clamp pipeline clamp connection system

A technology of pipe clamp and connection system, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the difficulty of double groove clamp processing and production, low reliability, easy to fall off the pipe, etc. problems, to achieve the effect of convenient construction, reliable pipeline connection and better sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

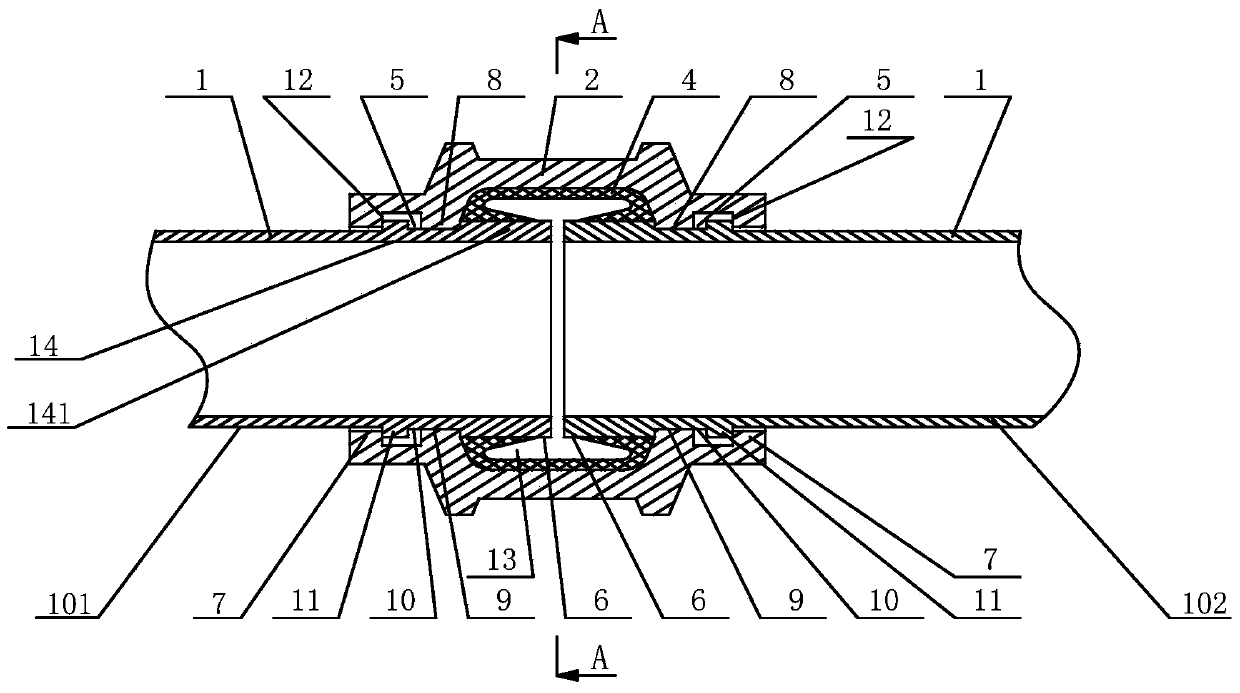

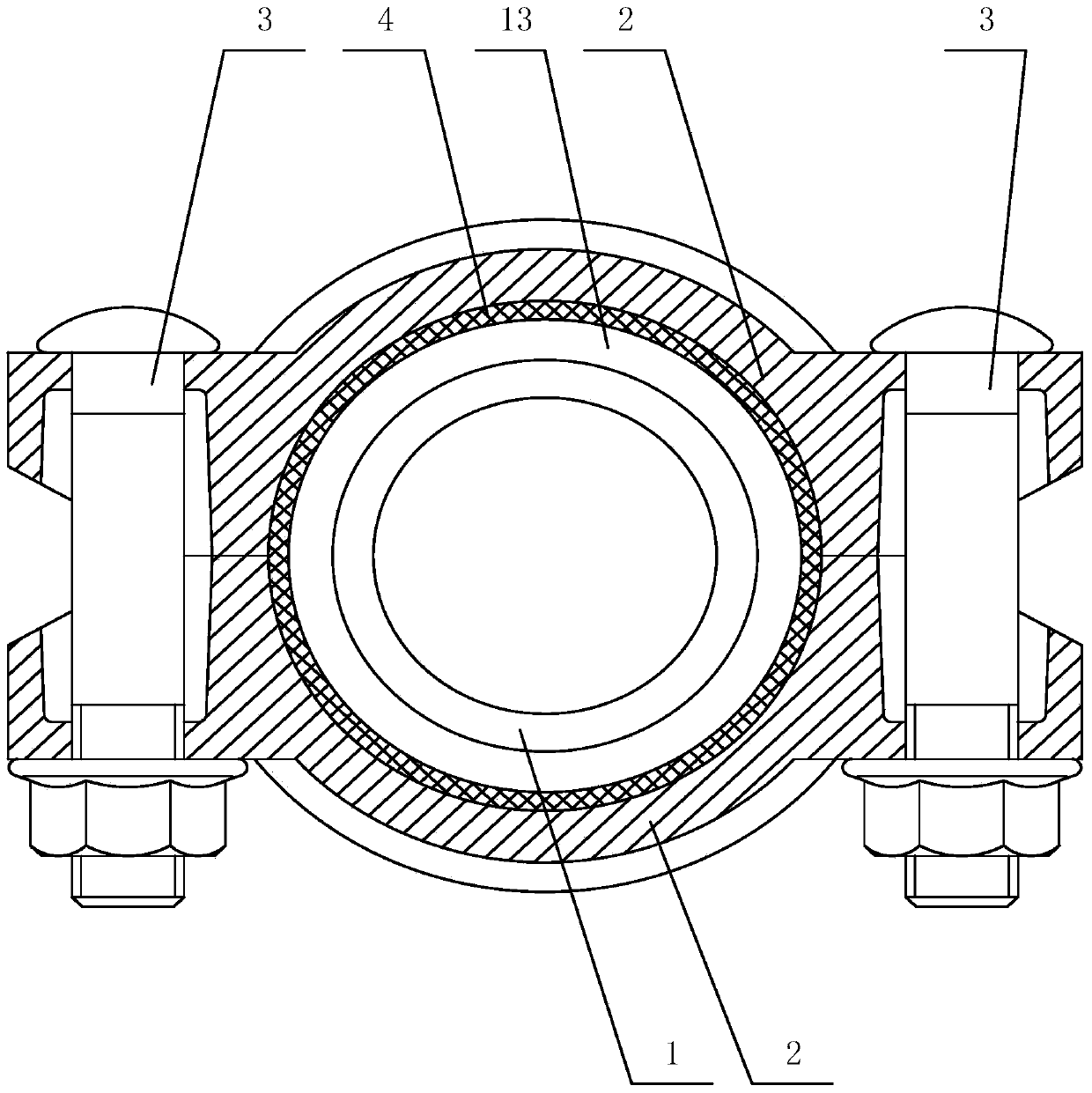

[0018] Such as Figure 1 ~ Figure 2 As shown, a pipeline clamp connection system with a single groove and double clamp structure includes a connecting pipe 1 and a clamp 2 for tightly connecting two adjacent connecting pipes 1, as shown in figure 1 As shown, the two adjacent connecting pipes 1 in this embodiment are the first connecting pipe 101 and the second connecting pipe 102 . The end of the connecting pipe 1 has a connecting end 14, the connecting end 14 of the connecting pipe 1 is a large pipe diameter section 141 near the nozzle, and the outer wall of the large pipe diameter section 141 is the sealing section 6 of the entire connecting pipe 1. After the first connecting pipe 101 and the second connecting pipe 102 are connected by the clamp 2, an airtight structure is formed at the sealing section 6 of the first connecting pipe 101 and the second connecting pipe 102 to ensure the airtightness of the two connected pipes. There is a groove 5 on the outer surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com