LED (light emitting diode) module and LED lamp manufactured by same

A technology for LED modules and LED lamps, which is applied to lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting components, etc. The effect of utilization rate, increased uniformity, high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

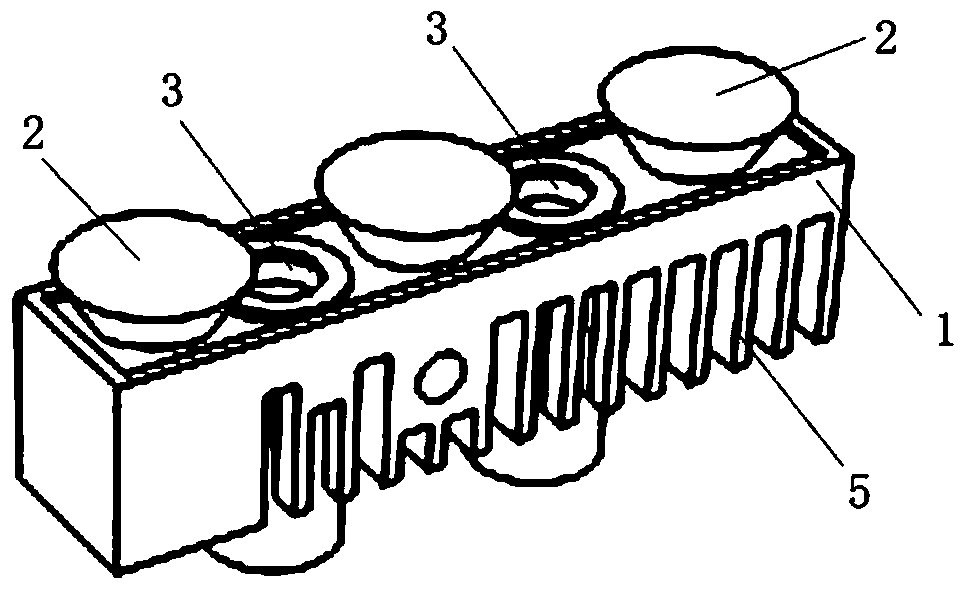

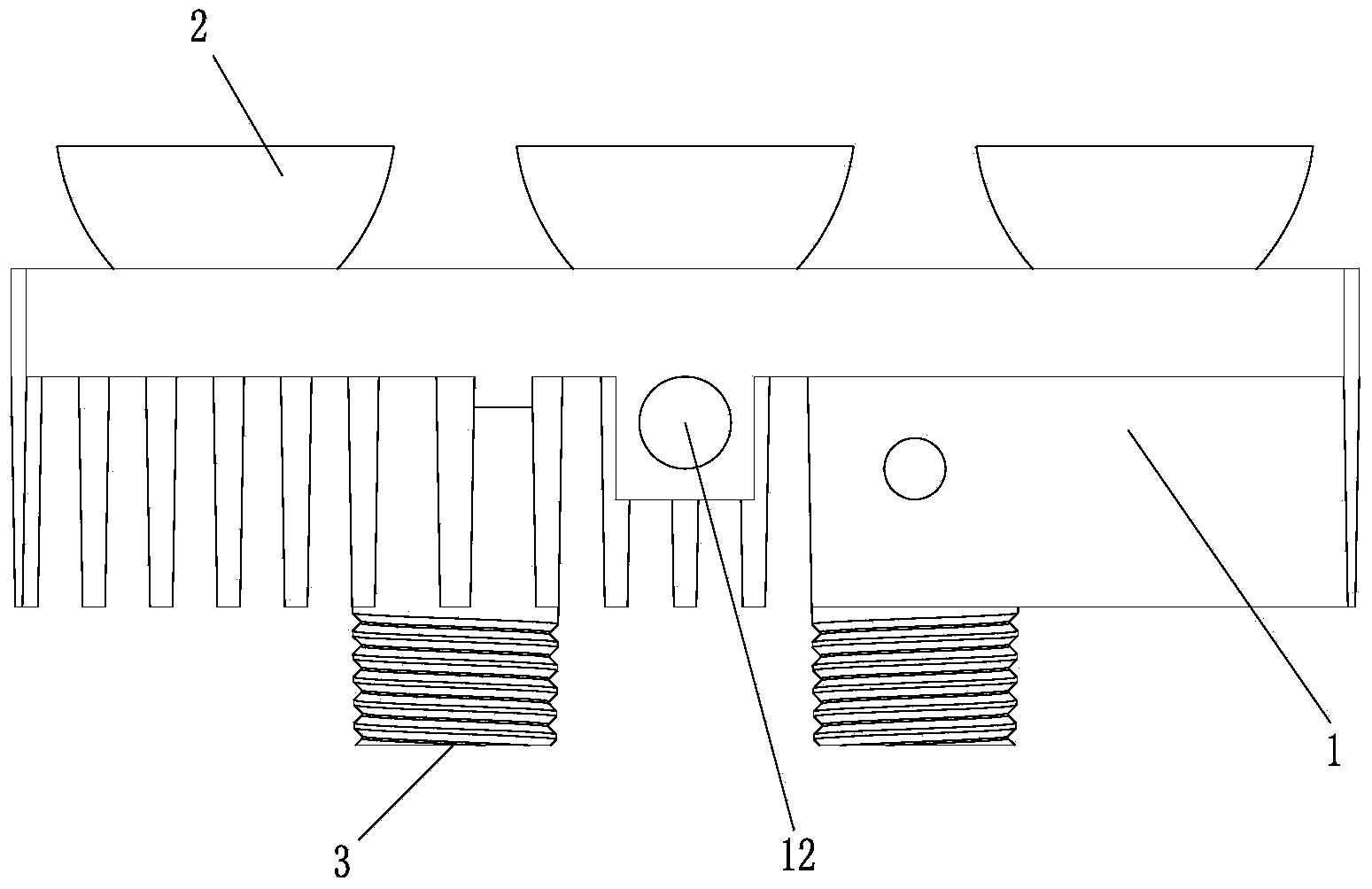

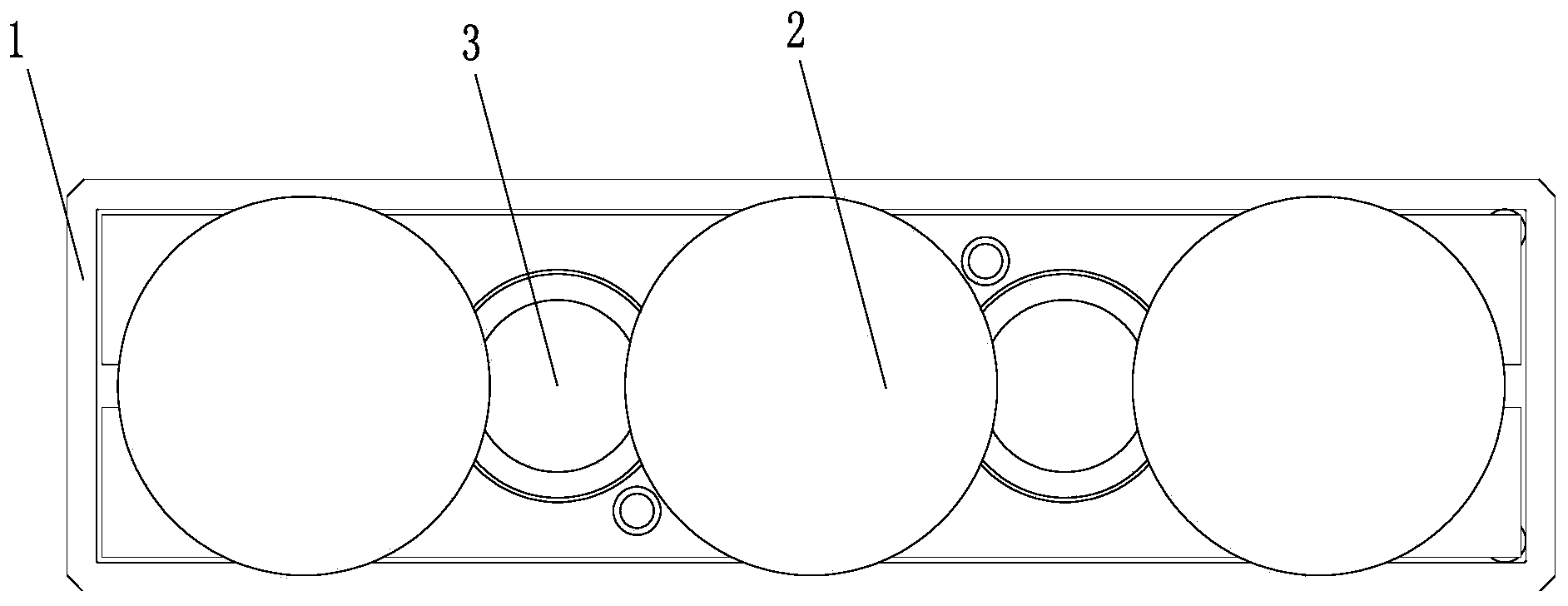

[0037] Such as Figure 1 ~ Figure 4 As shown, the LED module provided by this embodiment is very light and small in size, and it includes a base 1, an LED circuit board (not shown in the figure) fixed on the base, and a LED circuit board located on the base. The 3 LED lamp beads (not shown in the figure), these 3 LED lamp beads are distributed in a straight line on the LED circuit board, and each LED lamp bead is covered with a fixed on the LED circuit board Lens 2 on top. Moreover, several heat dissipation fins 5 and two air convection cooling holes 3 passing through the base are formed on the base 1 to ensure that the LED module has good heat dissipation performance, and the base in this implementation 1 Made of aluminum material with good heat dissipation.

[0038] In this embodiment, the outer contour of the base 1 is in the shape of a cuboid, such as figure 1 .

[0039] In this embodiment, the light emitting angles of all the lenses 2 fixed on the LED circuit board ca...

Embodiment 2

[0051] Such as Figure 9 ~ Figure 12 As shown, the structure of the LED module provided in this embodiment is similar to that of Embodiment 1, the main differences are:

[0052] a. In this example, the outer contour of the base 1 is in the shape of a regular hexagonal prism, on which 6 air convection cooling holes 3 penetrating the base are formed, and these 6 air convection cooling holes 3 are respectively arranged on the regular hexagonal prism on the six sides of the shape.

[0053] b. There are 6 LED lamp beads (not shown in the figure) on the LED circuit board, and the 6 LED lamp beads are distributed in a regular hexagon on the LED circuit board.

[0054] c. In this example, the base 1 is not provided with external threads surrounding the air convection cooling holes 3 , but a threaded hole 4 is formed at the center of the bottom of the base 1 . The purpose of this design is the same as the external thread surrounding the air convection cooling hole 3 in the first embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com