An ultra-precise measurement method based on multi-sensor scanning

An ultra-precision measurement, multi-sensor technology, applied in the field of measurement applications, can solve problems such as affecting measurement results and low signal-to-noise ratio, and achieve the effects of improving measurement speed, reducing measurement time, and reducing the amount of sampled data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

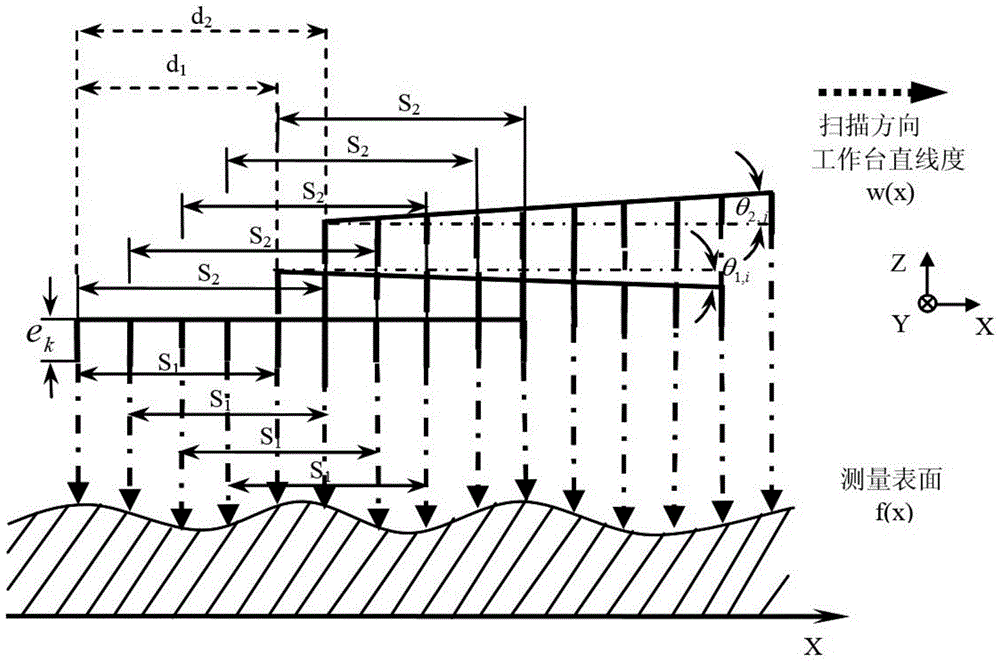

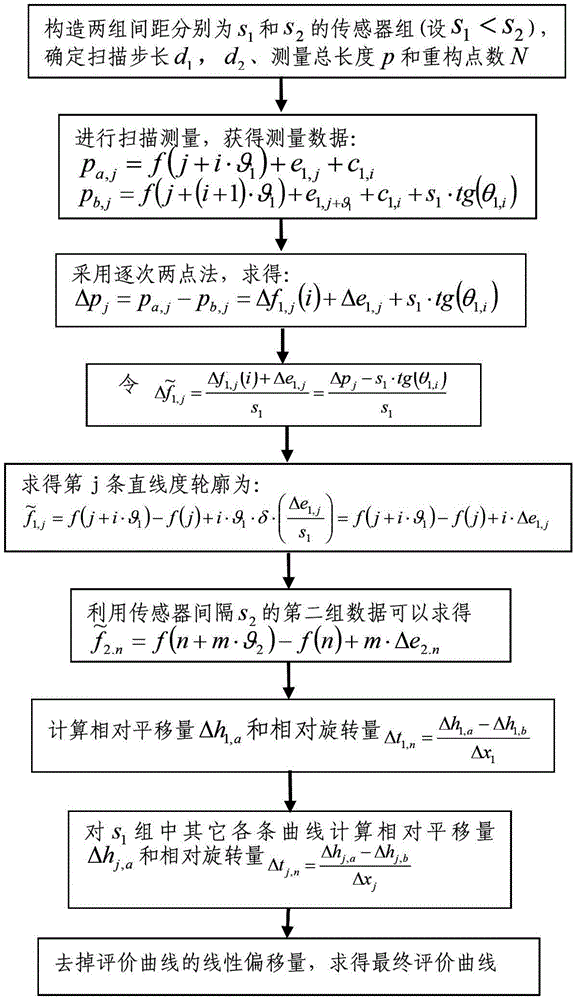

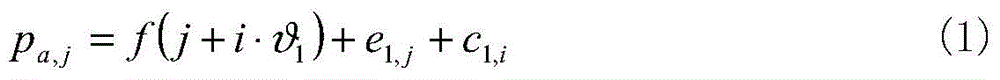

[0040] The successive two-point method can accurately reconstruct the straightness profile of the measured surface, but cannot determine its inclination and translation. The interferometer has a lot of pixels (that is, the distance sensor), and the spacing is small. Select a combination of sensors with a certain interval to implement successive two-point reconstruction. At this time, the reconstruction interval is equal to the selected sensor spacing (in order to improve the signal-to-noise Ratio / sensitivity, generally much greater than two effective pixel pitches), for the same section, every two sensors can reconstruct a straightness profile, but the relative positional relationship between these straightness profiles (relative inclination and translation amount) but need to try to determine.

[0041] In order to determine the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com