Ultrasound vortex flowmeter

A vortex flowmeter and ultrasonic technology, applied in the field of flowmeters and flowmeters for measuring gas flow, can solve the problems of unstable square wave sequence frequency, affecting readings, affecting the ventilation quality and breathing safety of artificial ventilators, and achieving low pressure Loss, improve stability, improve real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

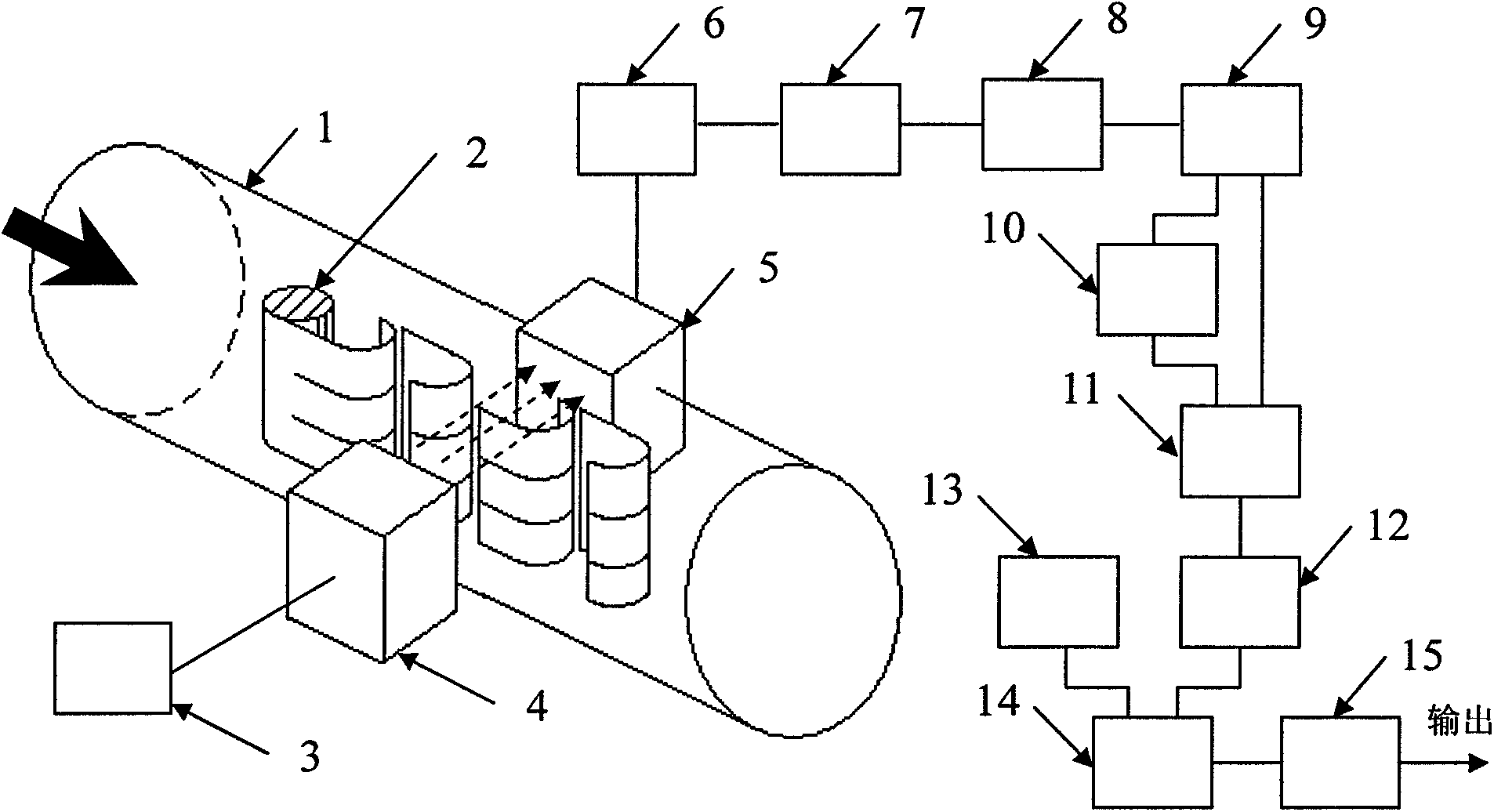

[0030] See figure 1 , An ultrasonic vortex flowmeter, consisting of a vent pipe 1, a vortex generator 2, an ultrasonic oscillator 3, an ultrasonic transmitting crystal 4, an ultrasonic receiving crystal 5, a first amplifier 6, a geophone 7, a second amplifier 8, Schmidt The flip-flop 9, the delay 10, the first multiplier 11, the first integrator 12, the oscillator 13, the second multiplier 14, the second integrator 15 and so on. The output of the ultrasonic oscillator 3 is connected to the input of the ultrasonic transmitting crystal 4, the output of the ultrasonic receiving crystal 5 is connected to the input of the first amplifier 6, the output of the first amplifier 6 is connected to the input of the detector 7, and the output of the detector 7 is connected. To the input of the second amplifier 8, the output of the second amplifier 8 is connected to the input of the Schmitt trigger 9, the output of the Schmitt trigger 9 is connected to the input of the delay 10, and at the sa...

Embodiment 2

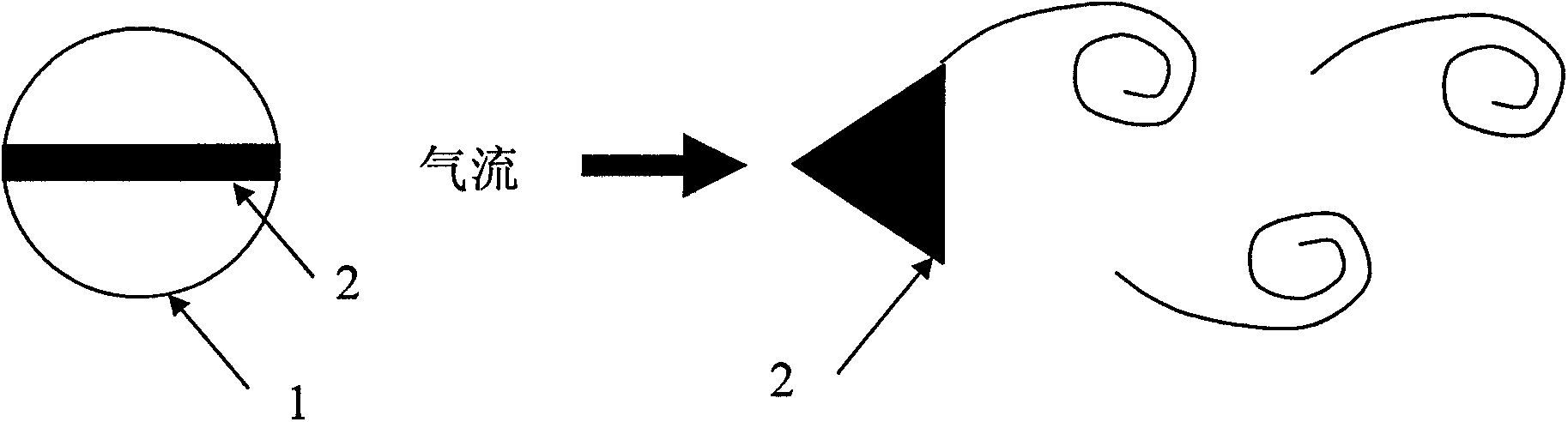

[0039] See figure 2 , The vortex generator 2 is a triangular column, which runs through the ventilation duct 1, and a vertex of the triangular column faces the direction of air flow. The ratio of the cross-sectional area of the triangular cylinder facing the air flow direction to the cross-sectional area of the air duct 1 is 1:50-1:2000.

Embodiment 3

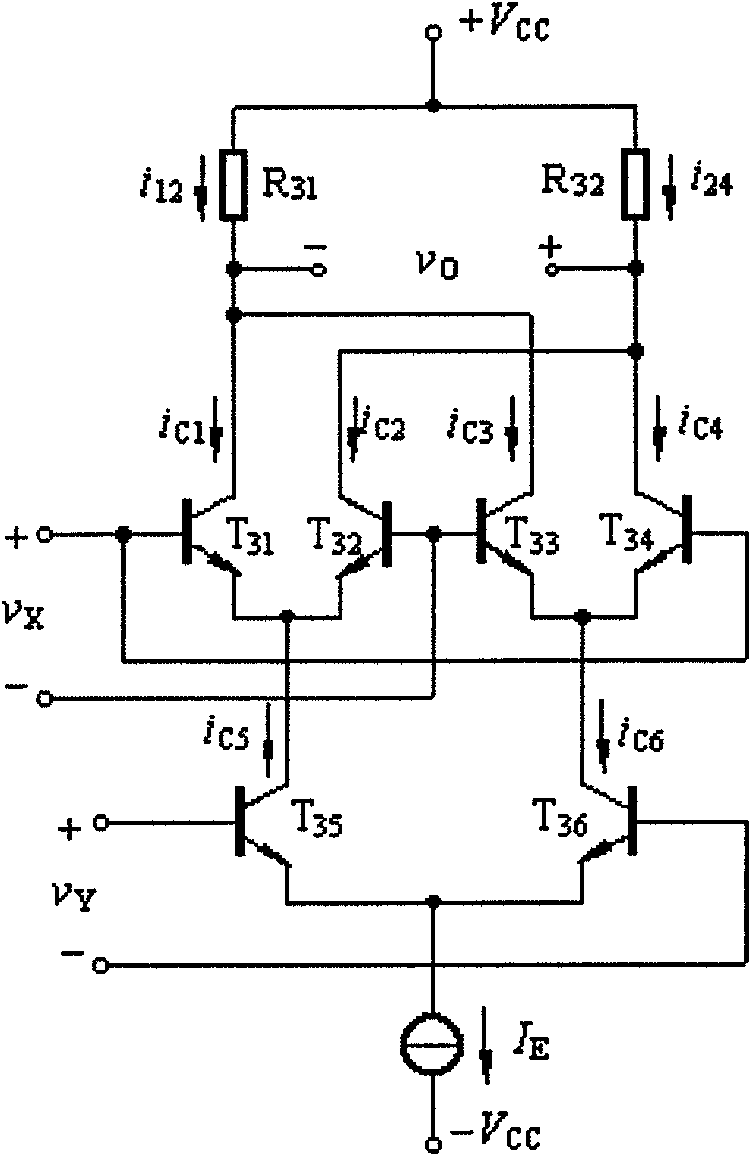

[0041] See image 3 , The first multiplier 11 and the second multiplier 14 are composed of a transistor T 31 , T 32 , T 33 , T 34 , T 35 , T 36 , Resistance R 31 , R 32 Double-balanced four-quadrant multiplier composed of other components, the input is v 1 And v 2 , The output is v o And there are:

[0042] v o =K m v x v y (3)

[0043] Where Is the multiplication coefficient, I E For T 35 And T 36 Emitter current, V T Is the cut-off voltage of the triode. In order not to saturate the output of the first multiplier 11 and the second multiplier 14 and cause the measurement range to be too small, the resistance R is adjusted 31 , Emitter current I E And choose the appropriate transistor cut-off voltage V T , So that the multiplication coefficient K m Between 0.01 and 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com