Durability test device for simulating ocean tidal action in artificial environment

A technology of durability test and artificial environment, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., it can solve the problems of inability to add artificial environment conditions, inability to control temperature and humidity, and inability to adjust wind speed, so as to increase the amount of water added. Protection device, low price, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

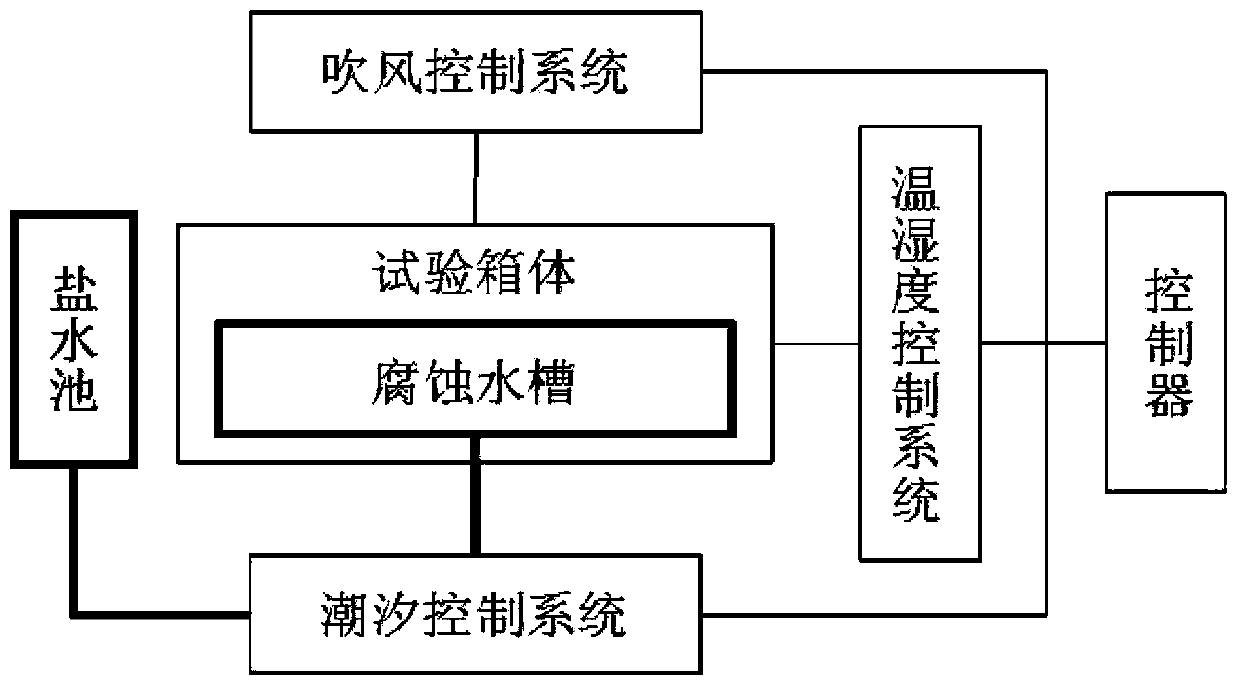

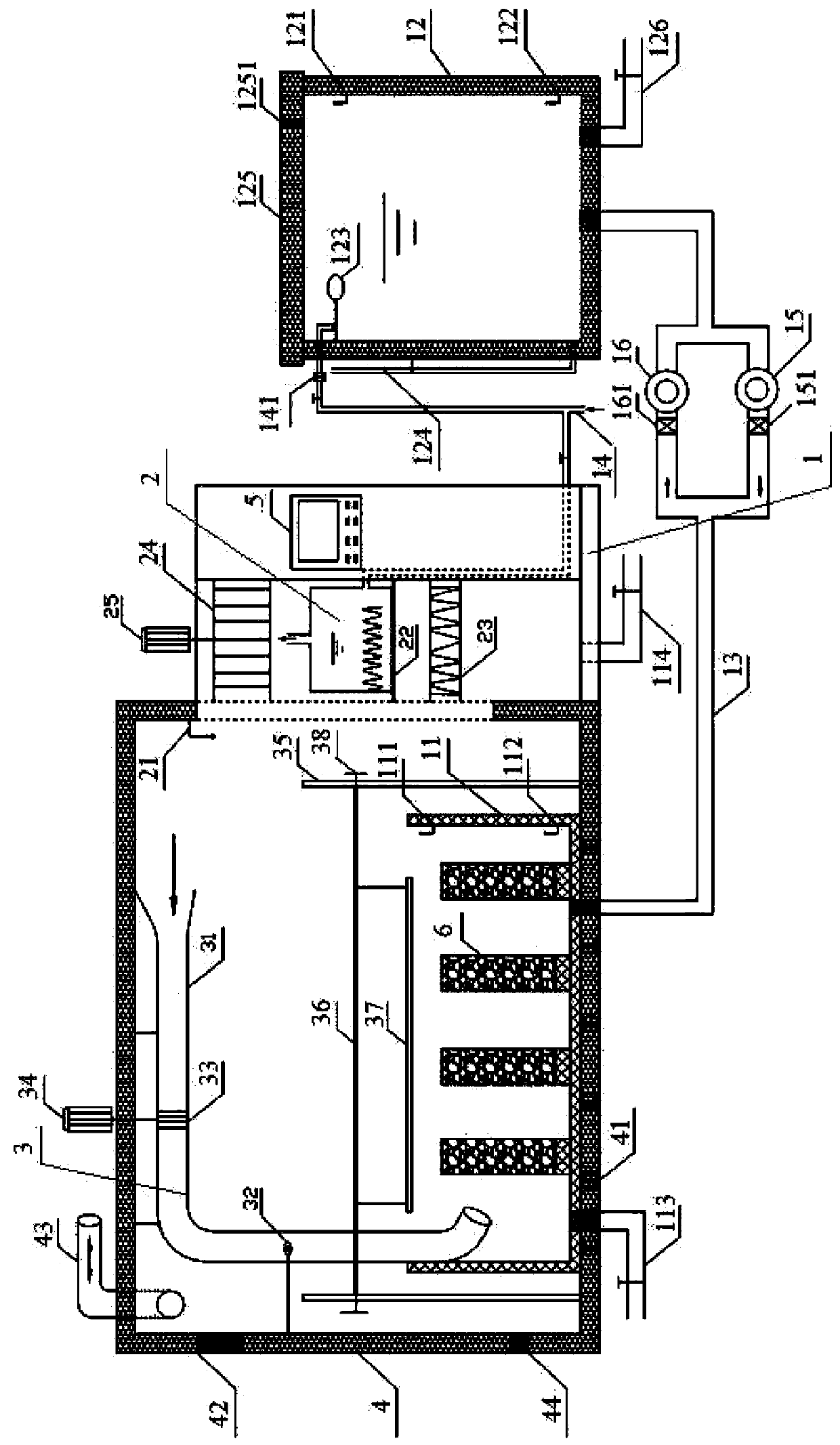

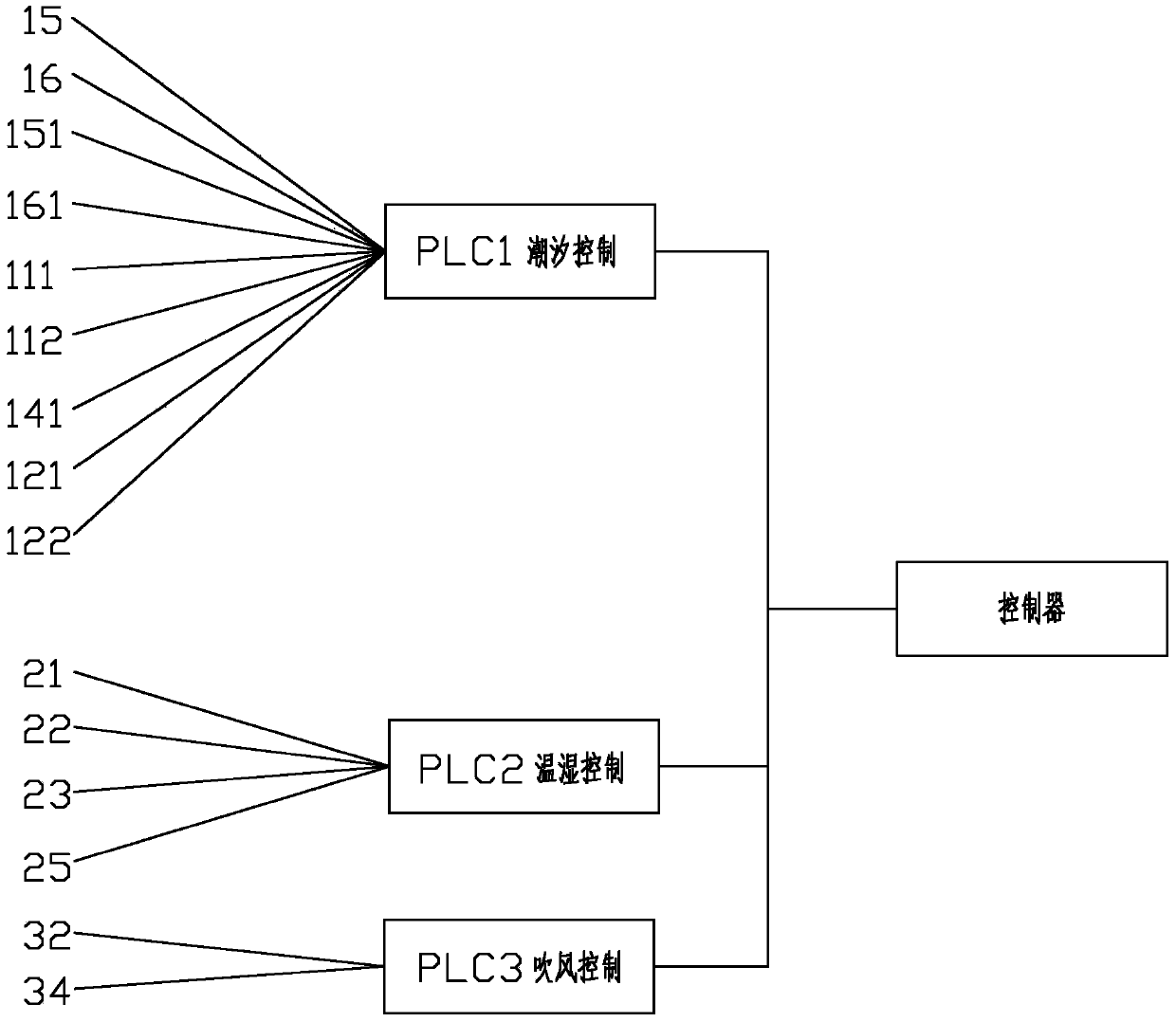

[0024] Embodiment 1 The durability test device for simulating ocean tide action in the artificial environment of the present invention comprises tide control system 1, temperature and humidity control system 2, blowing control system 3, test box body 4 and controller 5, and described tide The control system 1 includes a corrosion tank 11, a salt water tank 12, a water supply and drainage pipe 13, and a tap water inlet pipe 14. The corrosion tank 11 is placed in the test box 4, and the corrosion tank 11 and the salt water tank 12 are The water supply and drainage pipes 13 are connected between them, the corrosion tank 11 is provided with a first upper water level sensor 111 and a first lower water level sensor 112, and the inside of the brine pool 12 is provided with a second upper water level sensor 121 and a second lower water level sensor 122 The tap water inlet pipe 14 is connected with the brine pool 12 through the first electromagnetic valve 141, and the end of the tap wat...

Embodiment 2

[0036] Embodiment 2 is tested with the test device of Embodiment 1: test parameters are set on the controller: ambient temperature is 35°C, relative humidity is 70%, wind speed is 2m / s, and the tide system is 9:00~21:00 soaking process , 21:00~9:00 drying process, cycle 60 times. Suppose it is 9:00 at this time. After the parameters are set, start the program:

[0037] Before the test starts, put the test sample into the corrosion tank 11, calculate the volume of salt water required according to the volume of the concrete specimen volume and the volume of the corrosion tank 11, close the manual valves of the first drain pipe 113 and the third drain pipe 126, and the weighing Pour a good amount of solid salt into the brine pool 12, operate the controller 5 according to the control program, manually open the first electromagnetic valve 141, and determine the liquid level of the added tap water in the liquid level pipe 124 according to the required brine concentration and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com