Method for determining content of components in blended fiber

A technology of blended fiber and component content, applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of unstable signal strength and difficult control, etc., achieve high accuracy, convenient operation, simple and fast method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

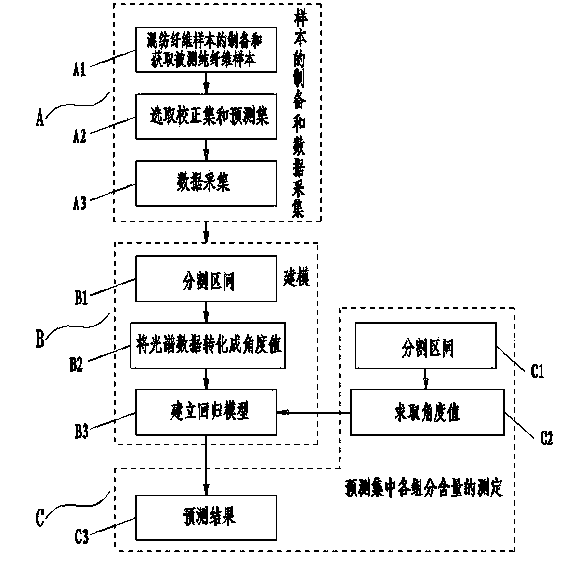

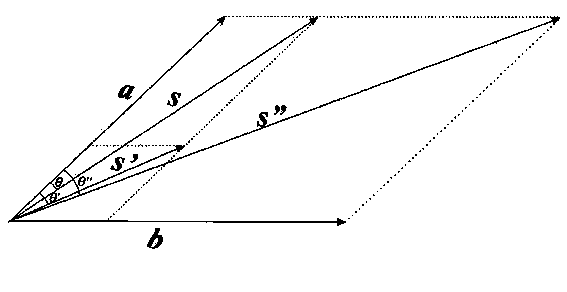

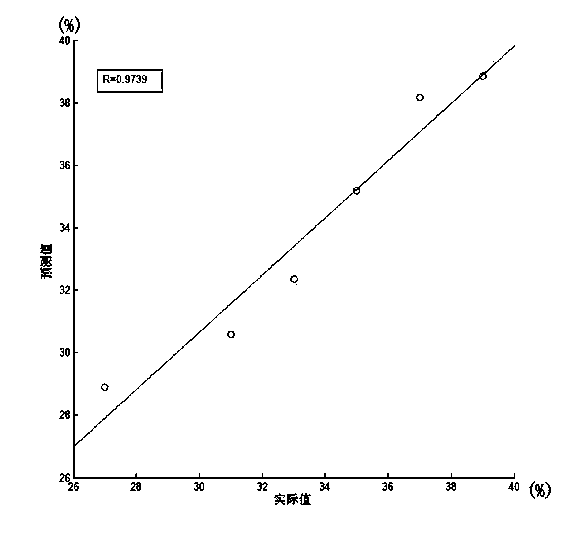

[0053] A method for determining the content of components in blended fibers. The blended fibers contain cotton, polyester and viscose. Now it is necessary to measure the contents of cotton, polyester and viscose in the blended fibers. The method first obtains the blended fibers and quilt Measure the near-infrared spectrum data of pure fibers - cotton, polyester and viscose, and then convert the obtained near-infrared spectrum data into the angle value between the blended fiber and cotton, polyester and viscose; select the modeled blended fiber sample as a calibration Set, the blended fiber sample to be tested is used as the prediction set, the content of cotton, polyester and viscose in the correction set is used as the dependent variable, the matrix formed by the correction set and the angle values of cotton, polyester and viscose is used as the independent variable, and the partial least squares method is used Establish a multivariate regression model; Substituting the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com