Easy-peeling-type flame-retardant thermal insulation cable

A flame-retardant cable, easy-stripping technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of casualties, equipment damage, easy damage, etc., to increase bending strength, reduce deformation, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

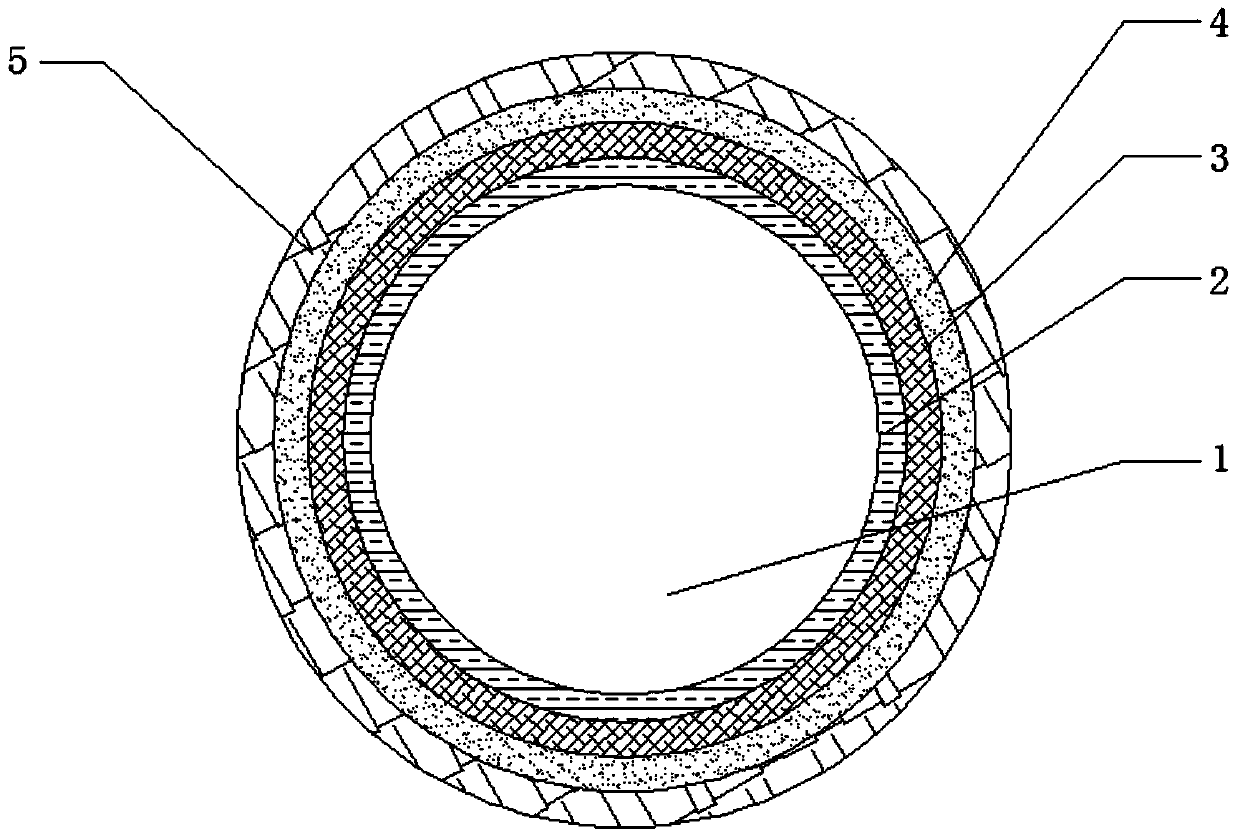

[0016] Please refer to figure 1 , is an easy-peelable heat-insulating and flame-retardant cable proposed by the present invention, comprising a wire core 1 and a shielding layer 2 arranged on the outer periphery of the wire core 1, and a heat-insulating and flame-retardant layer 3 is arranged on the outside of the shielding layer 2, The heat insulation and flame retardant layer 3 is provided with an insulating outer sheath 5 .

[0017] In this embodiment, the heat-insulating and flame-retardant layer is made of fiber cloth; the insulating outer sheath is a low-smoke, halogen-free, flame-retardant sheath made of polyethylene; and the shielding layer is made of semiconductor crosslinking material.

[0018] Please refer to figure 1 A filling material 4 is provided between the heat-insulating and flame-retardant layer 3 and the insulating outer sheath 5 , and the filling material 4 is peelably adhered to the insulating outer sheath 5 .

[0019] The filling material 4 is talcum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com