Trough type automatic feeding unit for breeding poultry

A kind of poultry breeding and automatic technology, applied in poultry industry, application, animal husbandry, etc., can solve the problems affecting poultry mechanization and large-scale management, the inability to control the feeding in time, the inability to control the supply of feed amount, etc., to reduce the Labor intensity and breeding cost, saving feed cost, and improving the effect of growth uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

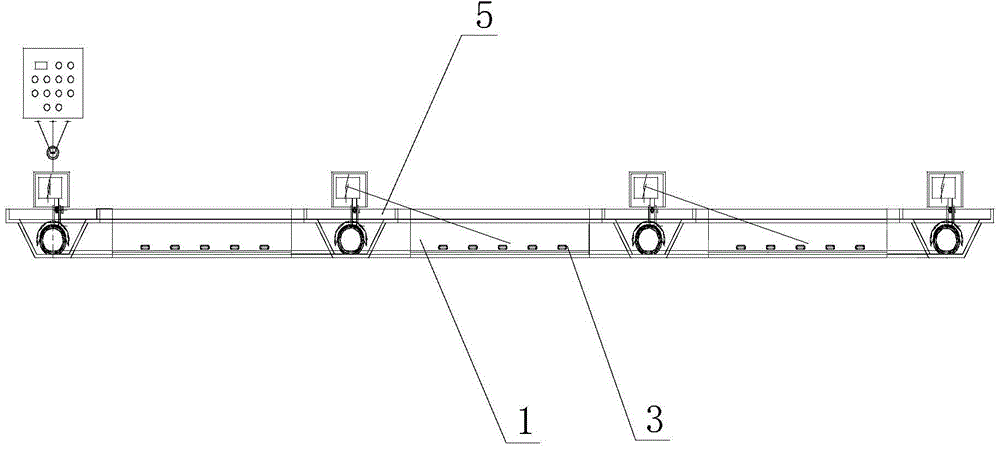

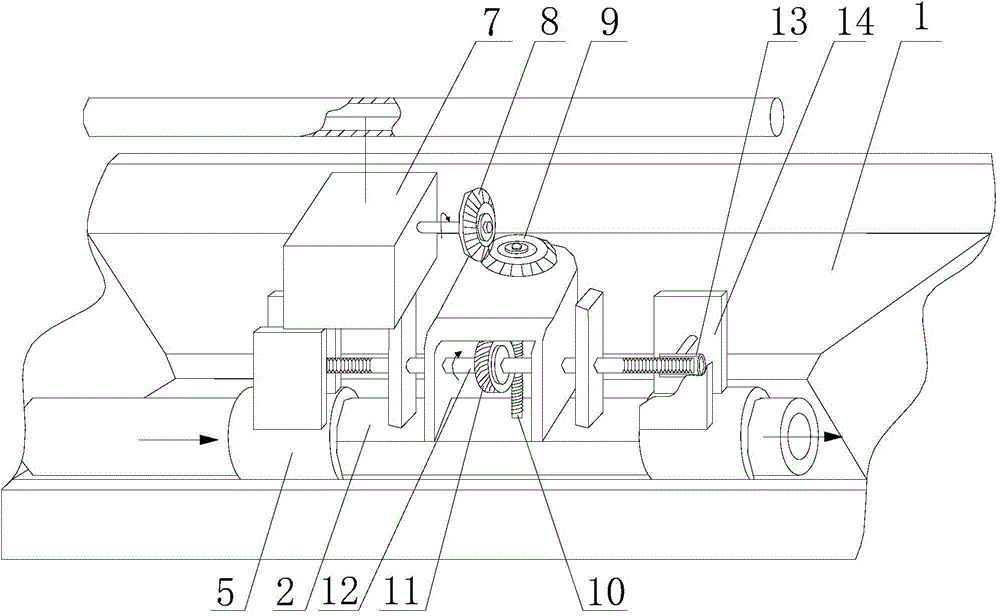

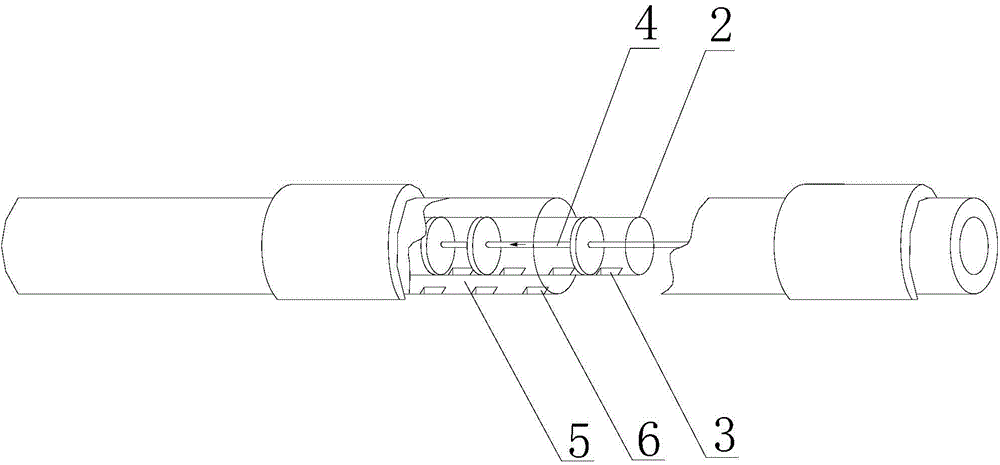

[0026] see figure 1 , figure 2 , image 3 and Figure 4 , a trough-type automatic feeding equipment for breeding poultry, mainly composed of a feed conveying device, a plurality of feed volume adjustment devices, a feed volume adjustment control device and a feeding tank 1, and the feeding tank 1 is designed as a continuous line along the extending direction of the feeding pipe 2 Or spiral design, the two ends of the feed conveying device are fixed on the two side plates of the feeding trough 1, including the horizontal linear feeding pipe 2, several discharge holes 3 on the pipe wall of the feeding pipe 2 and the 2. The feeding rod 4 inside and coaxial with the feeding pipe 2; the material volume adjustment device includes a material volume adjustment tube 5 located outside the material delivery pipe 2, and several tubes on the wall of the material volume adjustment tube 5 are arranged toward the feeding tank 1. The material volume adjustment hole 6 of the material and th...

Embodiment 2

[0032] see figure 1 , Figure 4 , the idea of this embodiment is basically the same as that of Embodiment 1, the difference is that the AC contactor control module can be set to multiple, the output ends are respectively connected to a plurality of material volume adjustment devices, and each material volume adjustment device is connected to monitor The material volume control sensor of the opening and closing degree and opening and closing time of the material volume regulating device.

[0033] When the feeding equipment is working, the PLC controller controls the operation of multiple feed volume adjustment devices at the same time, and can adjust the opening and closing degree and opening and closing time of the feed volume adjustment devices of the feeding equipment according to different feed requirements such as cubs and breeders, so as to realize different regions. , Precise feeding at different times and in different amounts facilitates the mechanization and large-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com