Supported catalyst preparing method and application of supported catalyst on electrode on dye-sensitized solar cell

A supported catalyst and solar cell technology, applied in the field of solar cells, can solve the problems of unsatisfactory carbon material adhesion and poor stability, and achieve the effects of easy control and operation, low equipment requirements, and rich material range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

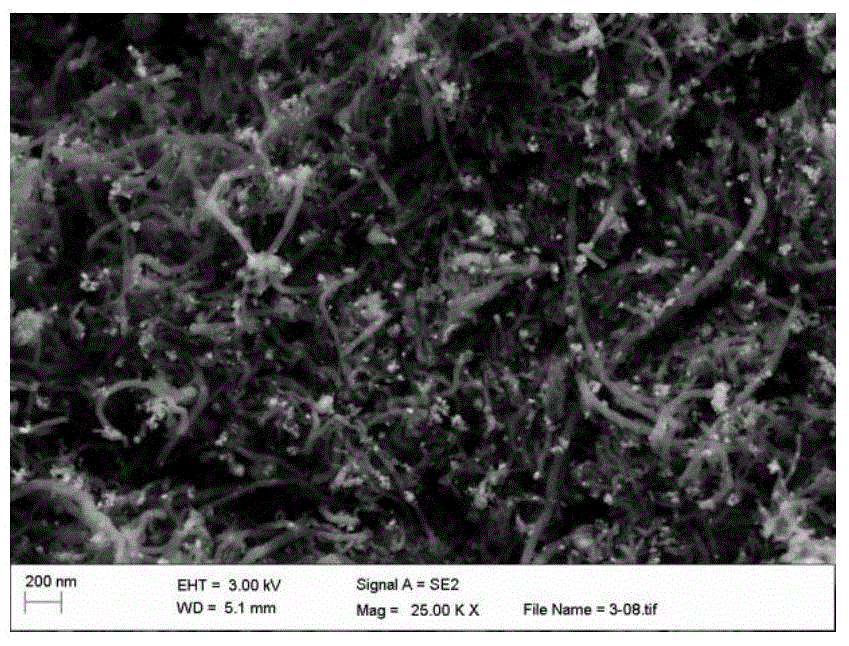

[0029] A method for preparing a supported catalyst, comprising the steps of mixing 0.6 mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, 0.6mmol of Cr(NO 3 ) 3 ·9H 2 O was dissolved in 20ml of distilled water; Co(NO 3 ) 2 Solution, Cr(NO 3 ) 3 The solution was mixed with 16.7 mmol of carbon nanotubes, immersed in the dark for 12 h, dried at 60 °C after dipping, and calcined at 500 °C for 3 h under nitrogen protection after drying.

Embodiment 2

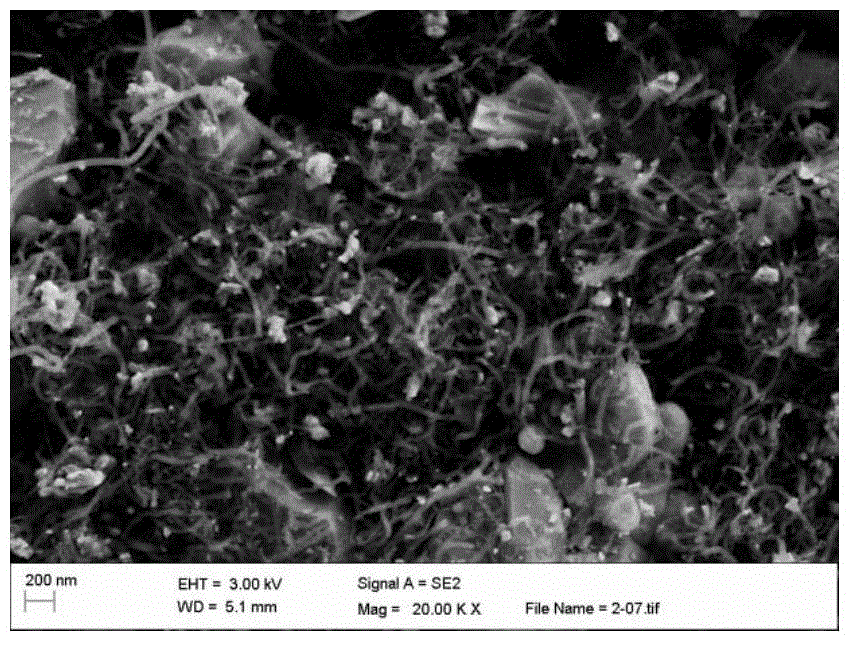

[0031] The difference from Example 1 is:

[0032] 0.4 mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, 0.6mmol of Cr(NO 3 ) 3 ·9H 2 O was dissolved in 20 ml of distilled water.

Embodiment 3

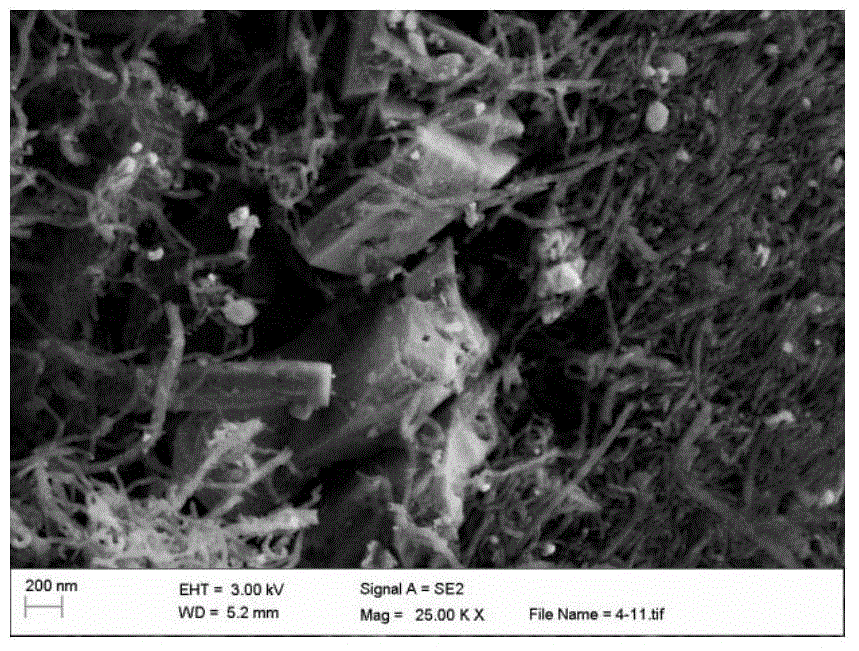

[0034] The difference from Example 1 is:

[0035] 0.6 mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, 0.4mmol of Cr(NO 3 ) 3 ·9H 2 O was dissolved in 20 ml of distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com