A storage and spraying device for release agent for rubber shredder

A technology of release agent and glue crusher, which is used in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of difficulty in controlling the amount of spraying, difficulty in spraying evenly, etc., and achieve the effect of spraying evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

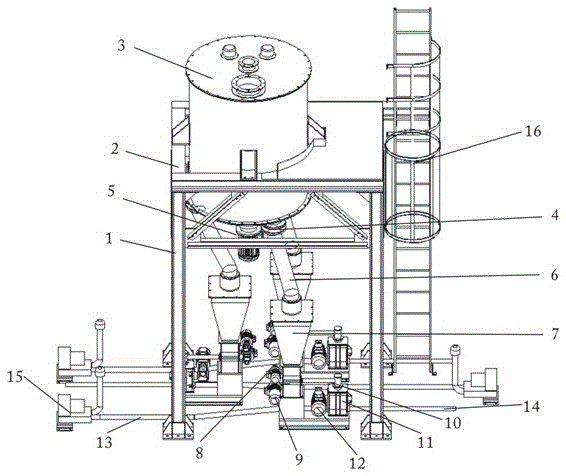

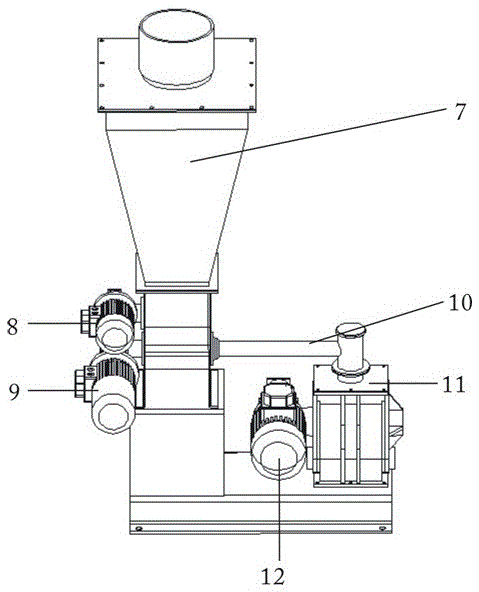

[0018] A kind of release agent spraying device for rubber shredder, such as figure 1 As shown, the support frame 1 and the top platform 2 form a rectangular support frame, and a cylindrical storage tank 3 is set on the top platform 2 for storing the release agent. The motor drive system 5 is used to stir the release agent to prevent precipitation and hardening. Three control butterfly valves 4 are arranged below the storage tank 3 to control the feeding speed of the release agent. The control butterfly valve 4 communicates with the hopper 7 through the feed pipe 6 .

[0019] The left side of the hopper 7 is provided with an anti-freezing motor drive system 8 and a blanking motor drive system 9. The anti-freezing motor drive system 8 drives the stirring device provided in the hopper 7 to prevent the release agent from depositing and hardening in the hopper 7. The blanking motor drive system 9 The screw conveying device installed in the drive hopper 7 is used to control the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com