Steam generator for garment steamer

A steam generator and garment ironing technology, applied in the field of garment ironing machines, can solve problems such as boiler water pollution, aluminum surface oxidation and dirt, etc., and achieve the effects of convenient processing and assembly, fast gas outlet speed, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The present invention intends to provide a steam generator with good water quality, large gas output and fast gas output. More specifically, the shape and material of the components constituting the steam generator are processed, including the shape of the heating element and the cavity. And size design and material selection. In some embodiments, one or more of the above-mentioned treatments may be provided, so as to ensure that the water quality and water vapor quantity in the steam generator achieve the desired effect.

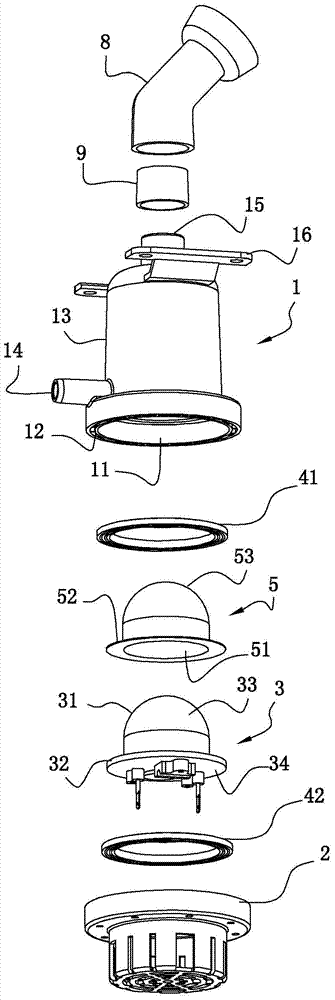

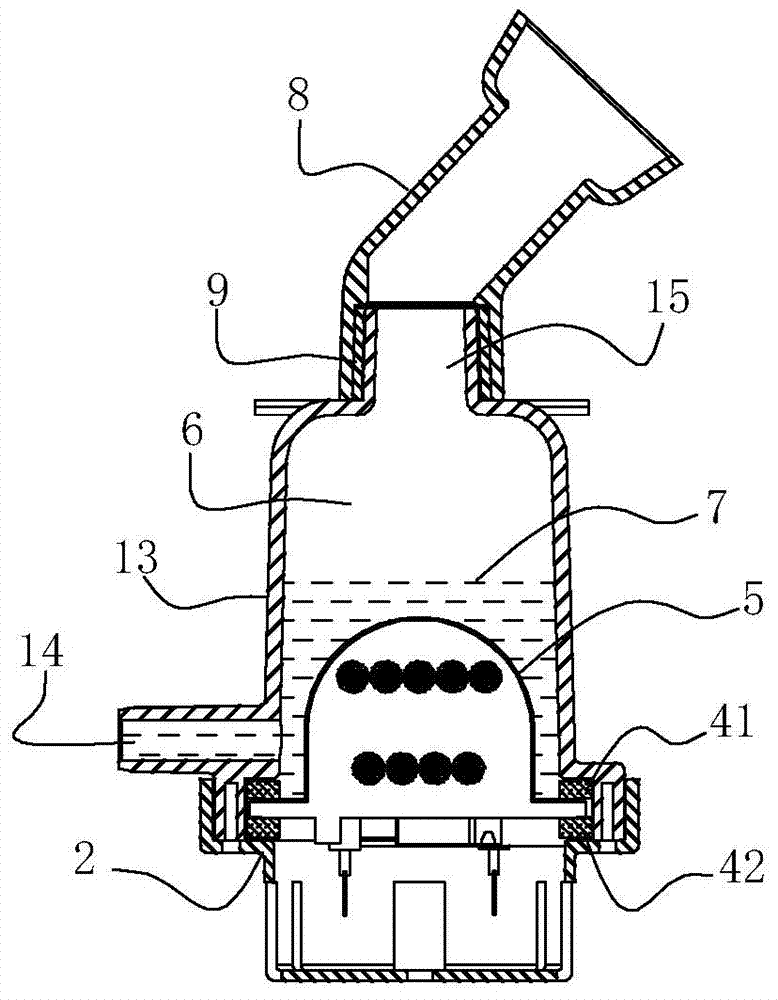

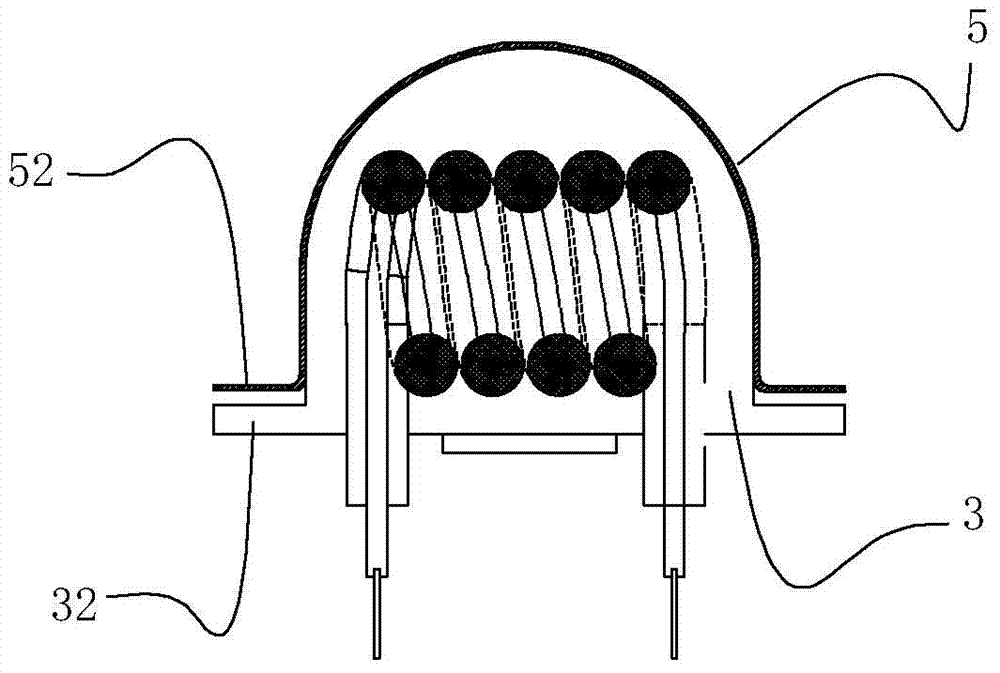

[0026] Such as Figure 1A , 1B , 1C, 3A, and 3B, the steam generator of the preferred embodiment of the present invention includes a cavity 1, a cover 2 located below the cavity 1, a heating element 3, a sealing ring 4 and a cover 5, the The cover 5 is set on the outside of the heating element 3 and has better ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com