Trough beam

A groove-shaped beam and groove-shaped technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of unsafe, large space occupation, poor installation stability, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

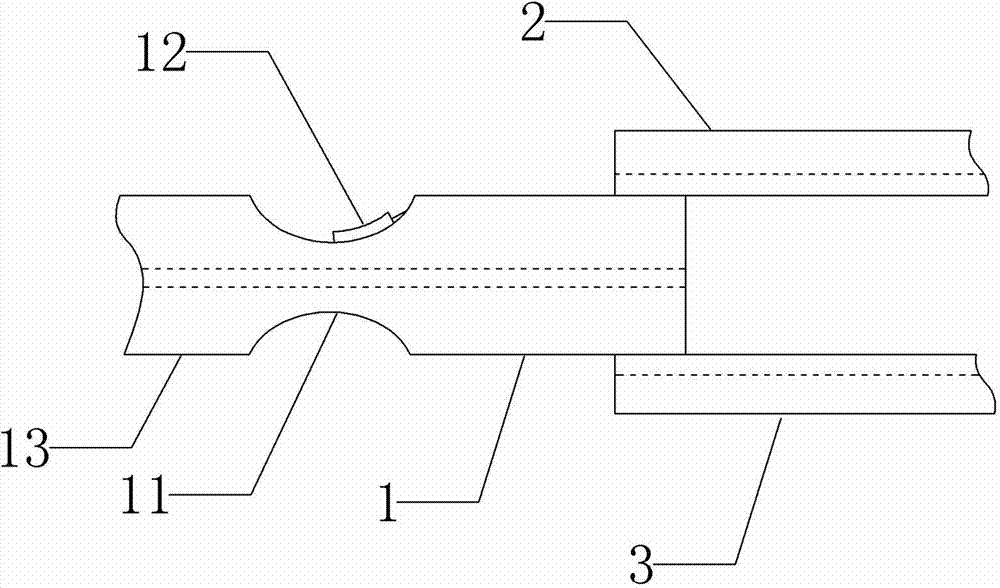

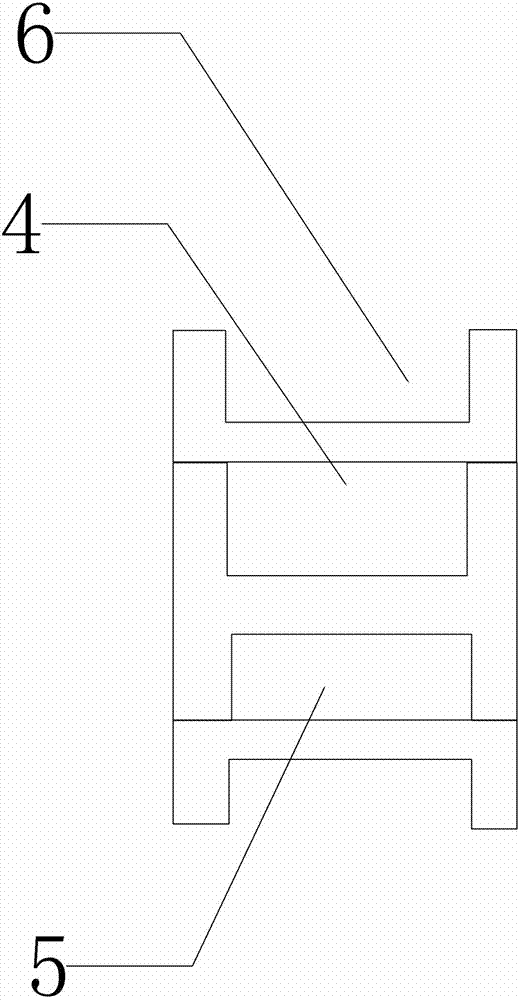

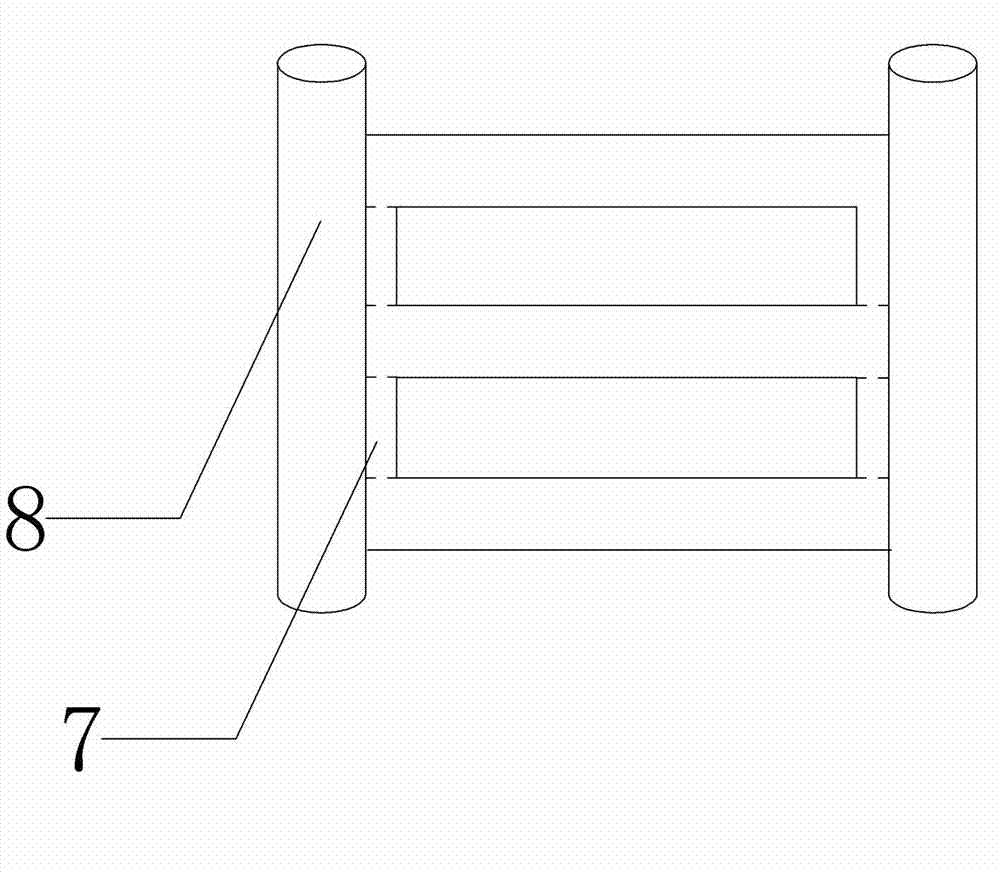

[0017] Such as figure 1 , figure 2 Shown is the schematic diagram of the channel beam of this embodiment, the channel beam includes a main beam 1, the main beam 1 is an I-shaped beam, one side of the main beam 1 is provided with a first side beam 2, and the other side of the main beam 1 A second side beam 3 is provided, the lengths of the first side beam 2 and the second side beam 3 are smaller than the length of the main beam, the widths of the main beam 1, the first side beam 2 and the second side beam 3 are equal, and the main beam 1 and the first side beam 2 form a first grooved channel 4 along the length direction of the main beam, a second grooved channel 5 is formed between the main beam 1 and the second side beam 3 along the length direction of the main beam, and the first side beam 2 and the second side beam 3 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com