Energy absorption connecting device

A connecting device and connecting technology, applied in the direction of shock absorber, spring/shock absorber, elastic shock absorber, etc., can solve the problems of reduced safety performance, complex structure, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

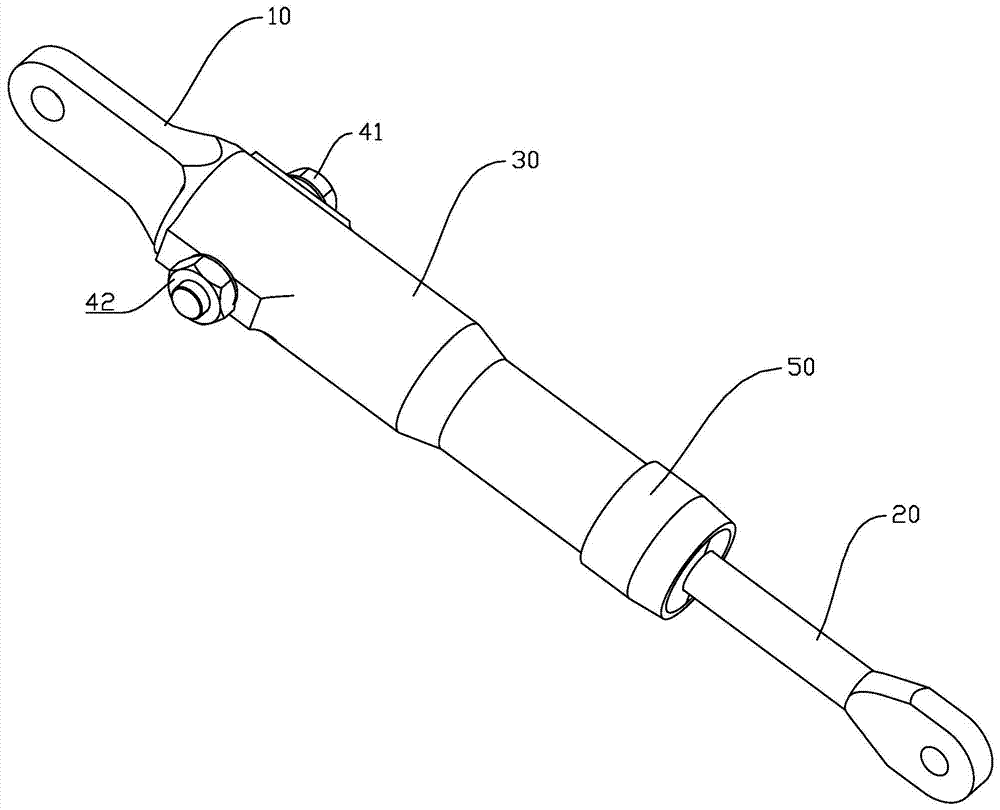

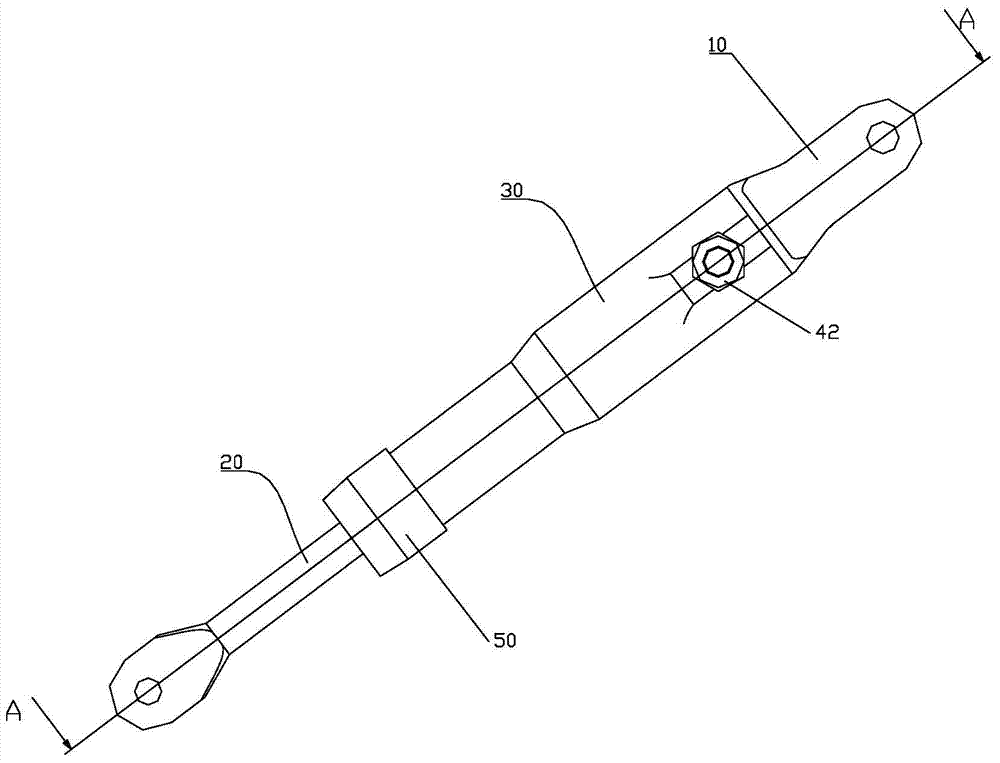

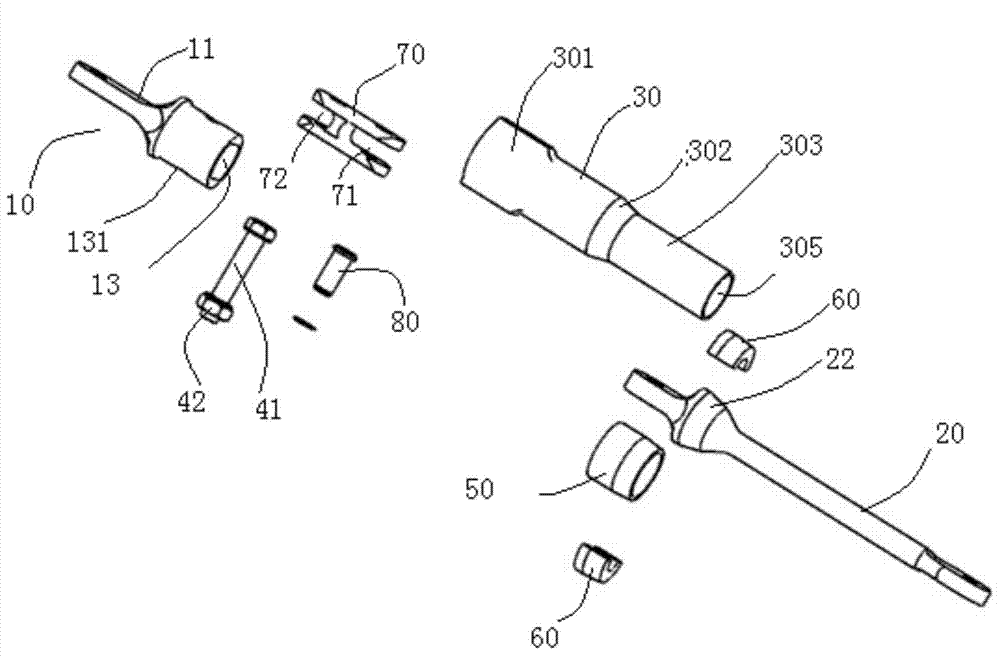

[0047] Such as Figure 1 to Figure 4 As shown, the energy-absorbing connection device is used to connect two connected devices, and includes a first joint 10, a second joint 20, and a connecting sleeve 30. The first joint 10 and the second joint 20 are respectively connected to a connected device. The connection method of the first joint 10 and the connected device can adopt the existing technology. The connection method of the second joint 20 and the connected device can adopt the existing technology. The cross-sectional shape of the first joint 10, the second joint 20, and the connecting sleeve 30 can be set according to the application. The cross section is a section perpendicular to the axis. In this embodiment, the cross section is circular as an example. The first joint 10 includes a flat connecting rod 11 and a cavity 13.

[0048] The connecting sleeve 30 has a tube wall 304 and a circular lumen 305. The connecting sleeve 30 has a accommodating section 301 and an exp...

Embodiment 2

[0056] Such as Figure 5 As shown, the difference in structure from Embodiment 1 is that only the first groove 71 is provided in the adapter 70. One end of the second groove 72 is a solid cylinder. The rest of the structure is the same as the first embodiment.

Embodiment 3

[0058] Such as Image 6 As shown, the energy-absorbing connection device is used to connect two connected devices, and includes a first joint 10, a second joint 20, and a connecting sleeve 30. The first joint 10 and the second joint 20 are respectively connected to a connected device. The connection method of the first joint 10 and the connected device can adopt the existing technology. The connection method of the second joint 20 and the connected device can adopt the existing technology. The cross-sectional shape of the first joint 10, the second joint 20, and the connecting sleeve 30 can be set according to the application. The cross section is a section perpendicular to the axis. In this embodiment, the cross section is circular as an example. The first joint 10 includes a flat connecting rod 11 and a cavity 13.

[0059] The connecting sleeve 30 has a tube wall 304 and a circular lumen 305. The connecting sleeve 30 has a accommodating section 301 and an expansion section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com