Gas corrosion characteristic testing apparatus

A characteristic testing and gas corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of equipment efficiency and finished product quality decline, and achieve convenient processing and operation, easy testing, and wide temperature range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

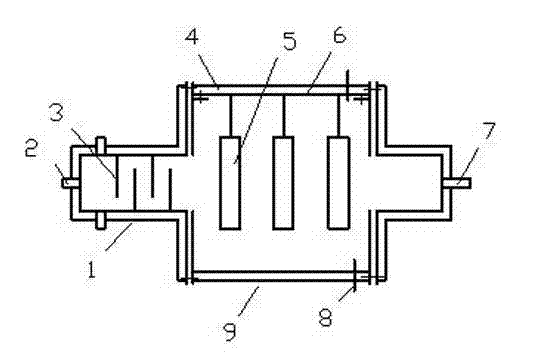

Embodiment 1

[0016] refer to figure 1 , a kind of gas corrosion characteristics testing device provided by the present invention, it is provided with gas mixing area 1 and coupon area 9 successively along gas flow direction between gas inlet 2 and gas outlet 7, the gas inlet on gas mixing area 1 has three One, the inside of the gas mixing area 1 is equipped with a baffle plate 3 forming a baffle, wherein, in the hanging piece area 9, a hanging piece 5 is installed perpendicular to the gas flow direction, and there are 3 hanging pieces 5 arranged along the gas flow direction. A cover plate 6 is installed above the piece area 9, and the hanging piece 5 is hooked on the bottom surface of the cover plate 6. The temperature measuring and sampling port 8 is installed on the hanging piece area 9, and an insulation layer 4 is installed on the surface of the overall device.

[0017] When the device is in use, the gas can be in contact with the coupons after good mixing, and the corrosion rate of th...

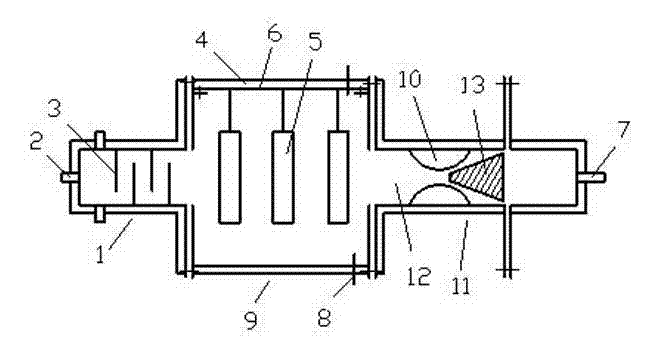

Embodiment 2

[0019] refer to figure 2 , the difference from Embodiment 1 is that a mixing and scouring area 11 is installed between the hanging piece area 9 and the gas outlet 7, and the mixing and scouring area 11 forms an air flow channel 12 with a circular cross section. The mixing and scouring The middle part of the gas flow channel 12 in the zone 11 has a convex circular constriction segment 10, and behind the convex circular constriction segment 10 there is a variable-diameter helix 13 with the apex of the cone in front. The surface of the convex constriction segment 10 is a streamlined structure, and the angle between the streamlined surface at the upper end and the vertical direction is 45° 0 , the angle between the streamlined surface of the lower end and the vertical direction is 35 0 The cross-sectional shape of the helix of the variable-diameter helix is circular, the helix diameter of the apex of the helix is 1.0 times the diameter of the helix, the pitch is 1.0 times th...

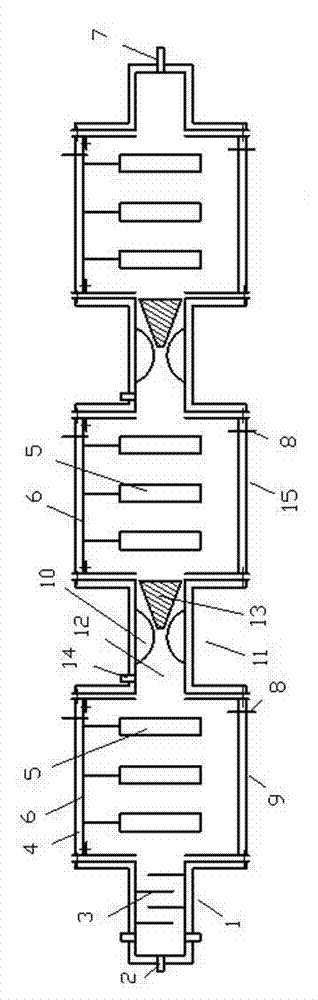

Embodiment 3

[0022] refer to image 3 An auxiliary functional area for investigating synergistic corrosion and scouring is installed between the hanging area 9 and the gas outlet 7. The auxiliary functional area is composed of two groups of mixing and scouring areas 11 and auxiliary hanging areas 15 connected to the hanging area 9 in sequence. A temperature-measuring sampling port 8 is installed on the hanging piece area 15. The mixing and scouring area 11 forms an air flow channel 12 with a circular cross section. There is a gas inlet 14 in the front of the slug 10, and a variable-diameter helix 10 with the tip of the cone in front at the back. The surface of the convex and constricted vein section is a streamlined structure, and the angle between the streamlined surface at the upper end and the vertical direction is 65° 0 , the angle between the streamlined surface of the lower end and the vertical direction is 45 0 The cross-sectional shape of the helix of the variable-diameter helix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com