Mounting structure and mounting method

A technology of installation structure and installation method, which is applied in the direction of circuit devices, electrical components assembled printed circuits, printed circuits, etc., can solve the problems such as difficult to suppress "sounding" and achieve the effect of suppressing ringing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

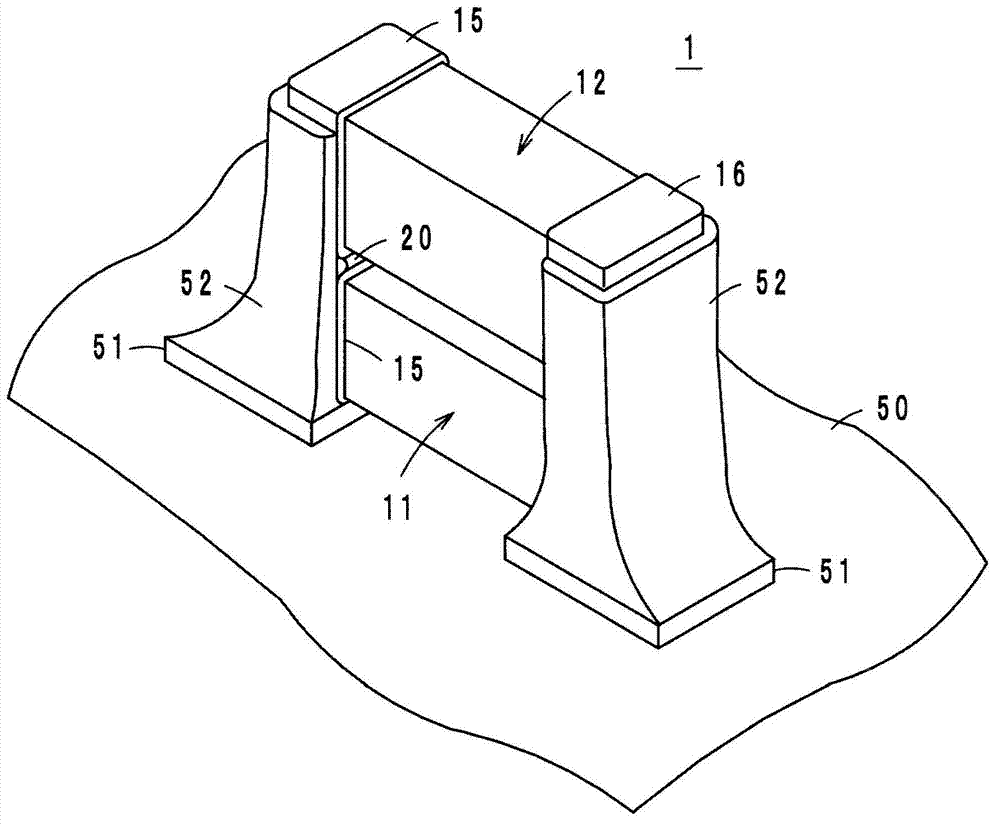

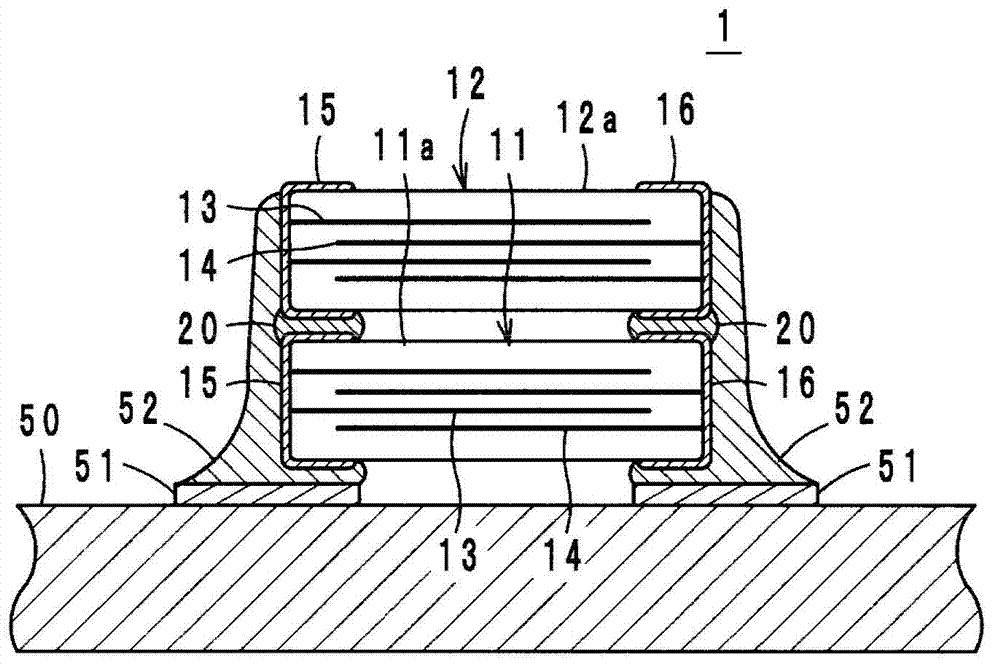

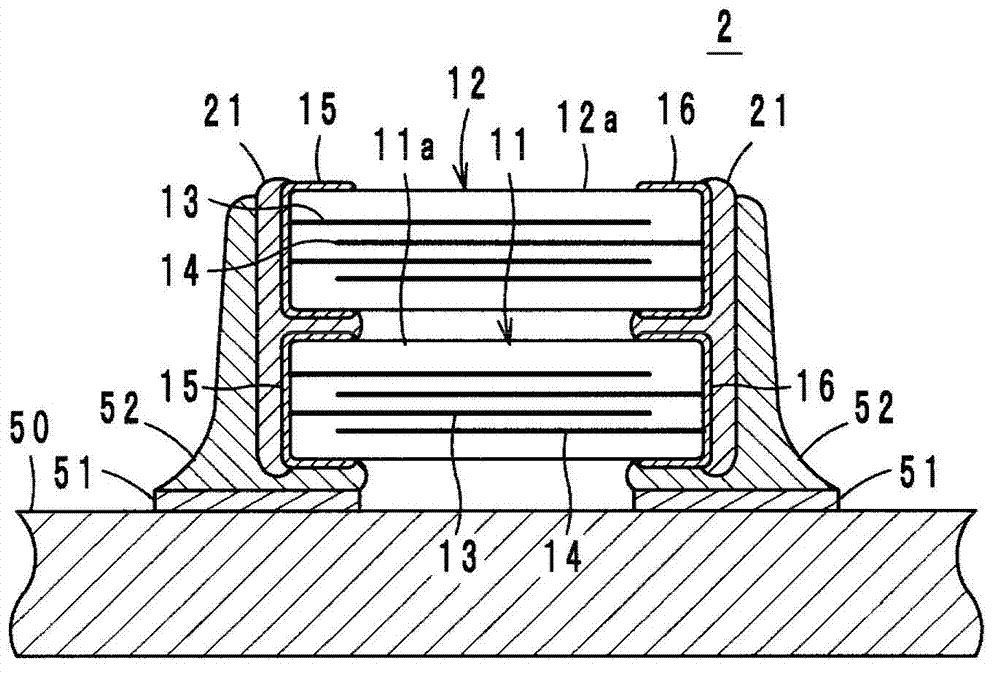

[0035] Hereinafter, embodiments of the multilayer capacitor of the present invention will be described with reference to the drawings.

[0036] Such as figure 1 and figure 2 As shown, the mounting structure 1 as an embodiment is constituted as follows: a second ceramic electronic component (second ceramic capacitor 12) is mounted on a first ceramic electronic component (first ceramic capacitor 11), and the first ceramic electronic component is bonded by solder 20. The external electrodes 15 , 16 of the electronic component and the second ceramic electronic component are joined to each other, and the external electrodes 15 , 16 are joined to pads 51 formed on the surface of the circuit board 50 via solder 52 .

[0037] In this mounting structure 1 , the solder 52 wets up to the external electrodes 15 , 16 of the upper ceramic capacitor 12 . It should be noted that, when the joint strength of the ceramic capacitors 11 and 12 by the solder 20 is sufficient, the joint to the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com