Device structure based on quasi-linear doping of III-nitride materials

A device structure, quasi-linear technology, applied in the direction of semiconductor devices, electrical components, diodes, etc., can solve the problems of poor F processing stability, quasi-linear doping difficulty, etc., to reduce difficulty, reduce implementation costs, and reduce current collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

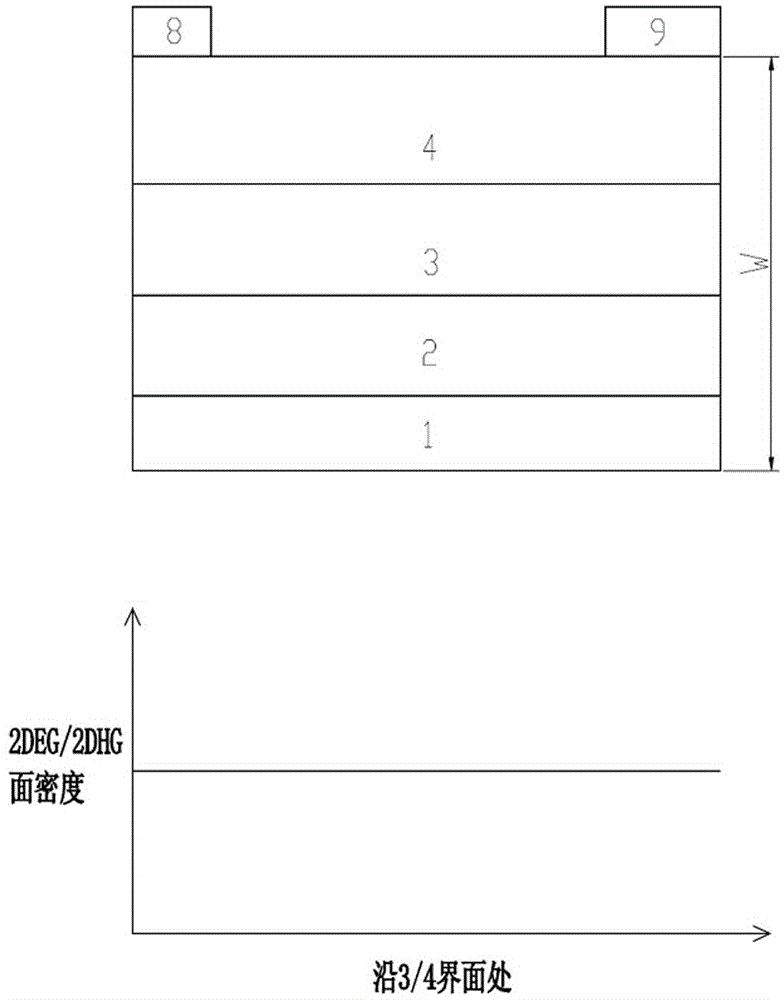

[0028] Depend on Figure 4 As can be seen, the quasi-linearly doped SBD device structure based on Group III nitride materials includes a substrate 1, a buffer layer 2, a channel layer 3 and a barrier layer 4 from bottom to top, and the barrier layer 4 An anode electrode 8 and a cathode electrode 9 are arranged at both ends of the upper surface; the upper surface of the barrier layer 4 increases stepwise, and the increasing direction is from the anode electrode 8 to the cathode electrode 9 . Because the changing direction of the incremental part should be gradually increasing from the low-potential electrode to the high-potential electrode under the reverse cut-off state of the device; 9 is a high potential voltage, so from Figure 4 It can be observed that the stepwise increase is from left to right.

[0029] In this embodiment, the incremental part starts from the anode electrode 8 at the left end of the barrier layer 4 and increases to the cathode electrode 9 at the right ...

Embodiment 2

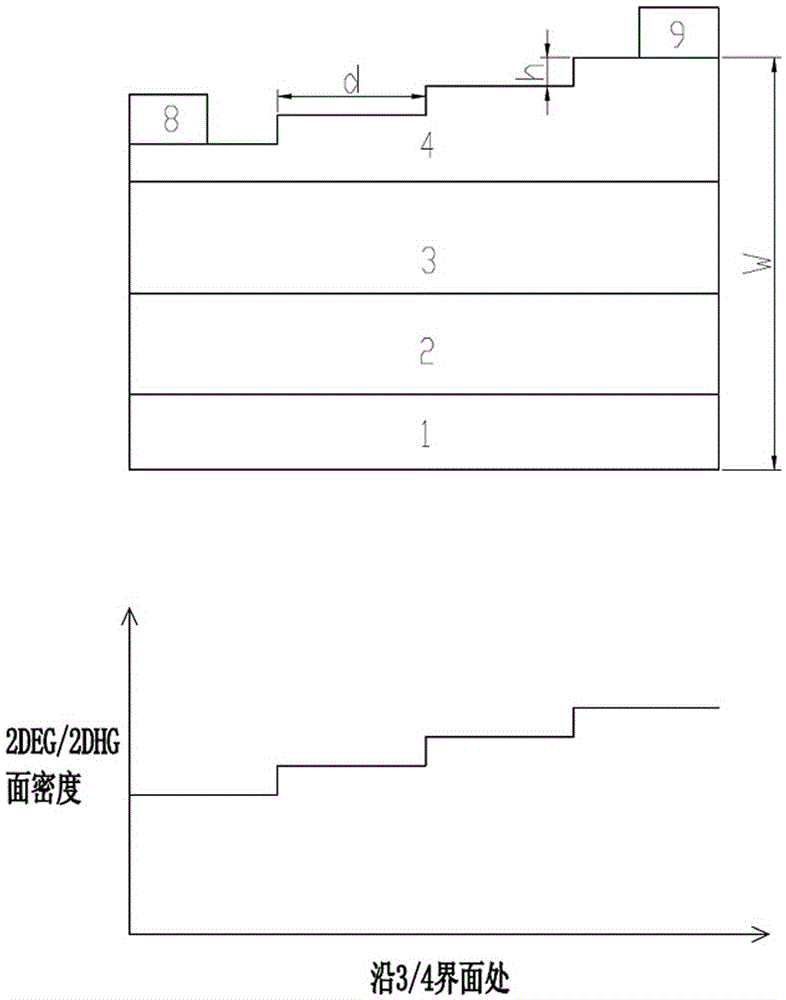

[0039] Such as Image 6 It can be seen that, unlike Embodiment 1, part of the upper surface of the barrier layer 4 increases in steps. Depend on Image 6 It can be seen that the stepwise increasing direction is increasing from right to left, and the increasing direction is just opposite to that of Embodiment 1. The rule of the direction: in the reverse cut-off state of the device, gradually increase from the low-potential electrode to the high-potential electrode. In this embodiment, the stepwise increasing direction should be from right to left.

[0040] The difference between this embodiment and Embodiment 1 is that: 1) the stepwise increasing part occupies part of the upper surface of the barrier layer 4; 2) the height difference h between the steps is different; 3) the width d of each step is also 4) The height of the highest step is lower than the equal plane height W of the barrier layer 4 .

[0041] Substrate 1 is diamond in the present embodiment; Buffer layer 2 is ...

Embodiment 3

[0043] Such as Figure 8 As shown, the HEMT structure based on the quasi-linear doping of group III nitride materials includes a substrate 1, a buffer layer 2, a channel layer 3 and a barrier layer 4 from top to bottom; different from Embodiment 1, the The upper surface of the barrier layer 4 is provided with a source electrode 5 , a gate electrode 6 and a drain electrode 7 . The height of part of the upper surface of the barrier layer 4 increases stepwise, and this part is located between the gate electrode 6 and the drain electrode 7 on the barrier layer 4 , which is similar to the position of the second embodiment. The increasing direction is from the gate electrode 6 to the drain electrode 7, and here also follows the rules of the increasing direction: in the reverse cut-off state of the device, it gradually increases from the low potential electrode to the high potential electrode, and in the cut off state, the gate electrode 6 is applied with a low potential voltage, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com