Die bonding procedure of in-line LED bead packaging technology

A technology of LED lamp beads and packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as error-prone work efficiency, and achieve the effect of improving the quality of die-bonding processing, high processing efficiency, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

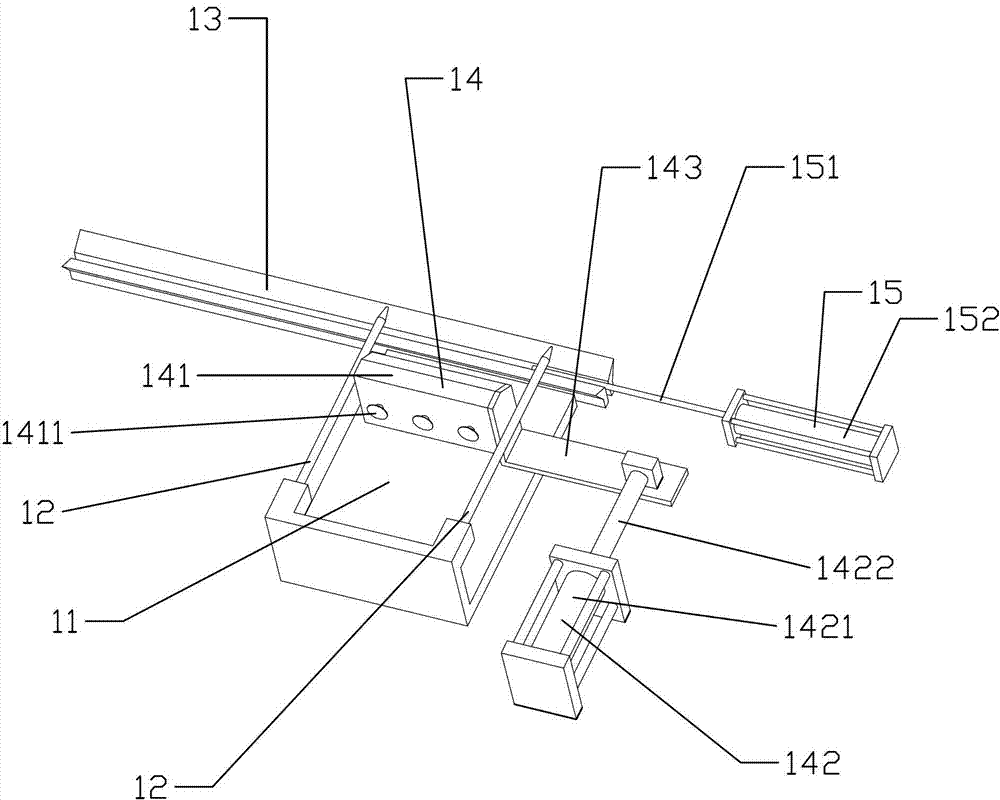

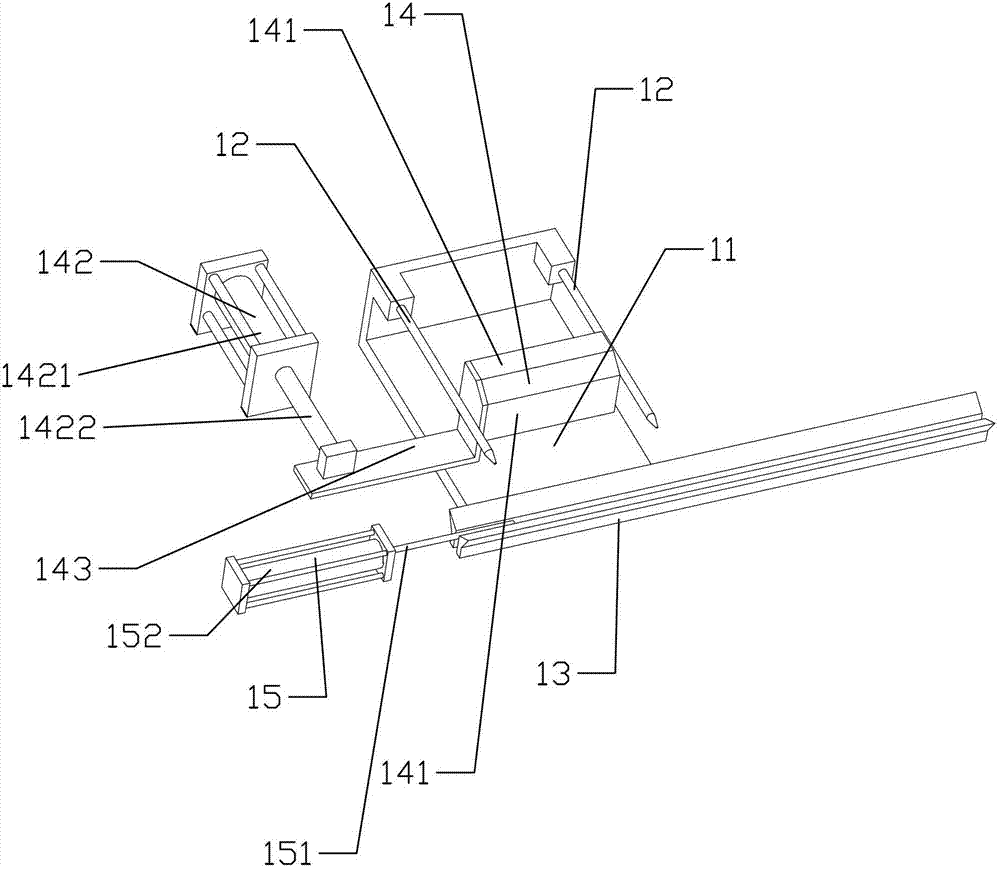

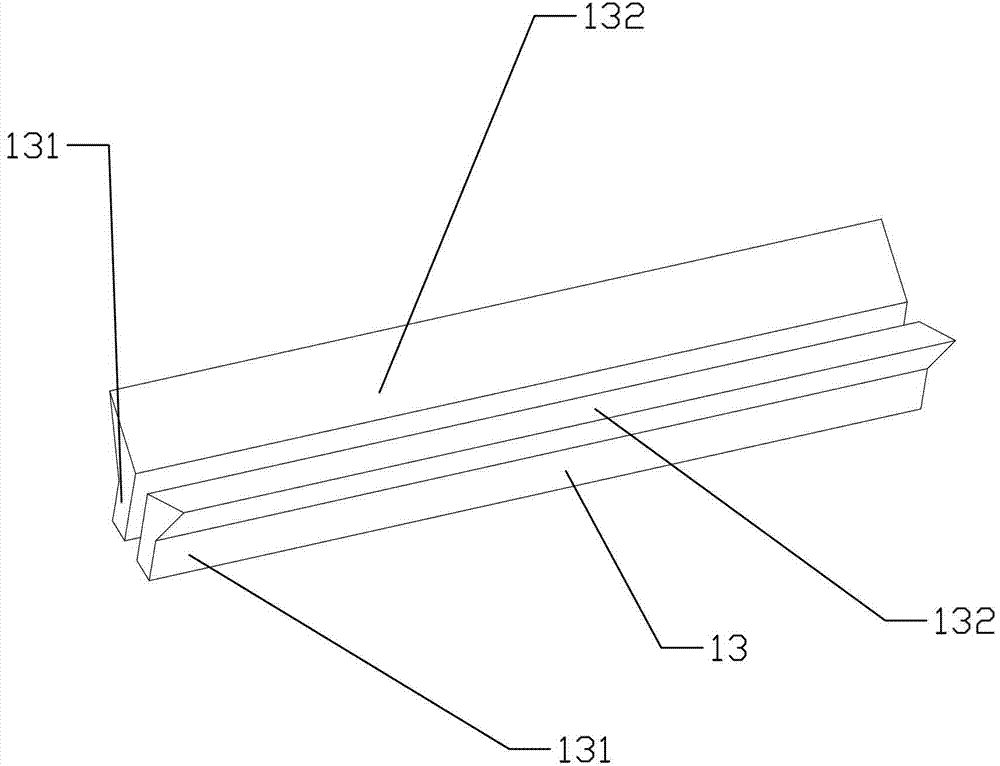

[0023] Such as Figure 1-7 As shown in the specific embodiment of the present invention, the crystal bonder used in the crystal bond operation of the present invention directly adopts the conventional crystal bonder on the market, such as the crystal bonder produced by Shenzhen Xinyichang Equipment Company.

[0024] Operation of the present invention comprises the following steps:

[0025] (1) Feeding, fix the positive and negative pins on the bracket of the crystal bonder, then transport the bracket to the processing position of the middle crystal bonder through the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com