Syringe putter with o-type ring rubber plug

A technology for a syringe and a rubber stopper is applied in the field of a syringe push rod with an O-ring rubber stopper, which can solve the problem of the large radius of the circular arc of the tip of the rubber stopper sealing ring, the large contact area between the rubber stopper and the liquid medicine, and the tip of the sealing ring ring falling off. Difficulty in molds and other problems, to achieve the effects of product safety, reduction of raw material costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

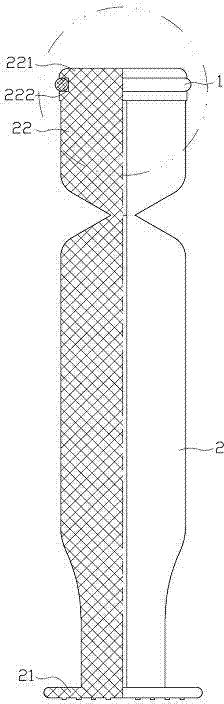

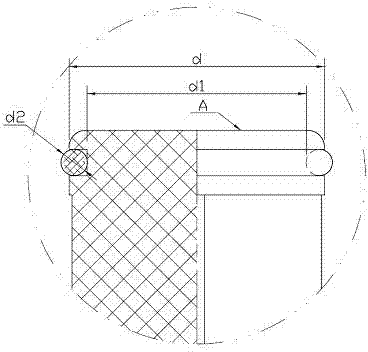

[0015] Such as figure 1 , 2 As shown, it includes an o-ring rubber plug 1 and a push rod body 2. The lower part of the push rod body 2 is provided with a pusher 21, and the upper part of the push rod body 2 is provided with a push rod head 22. A push-pull ring 221 is formed on the push rod head 22. The feature is: the push-pull ring 221 is provided with a groove 222 for installing the o-ring rubber plug 1 , and the groove 222 is located in the middle of the push-pull ring 221 .

[0016] Wherein, the diameter d of the push-pull ring 221 is slightly smaller than the inner diameter of the syringe barrel.

[0017] Wherein, the top surface A of the push-pull ring 221 is a plane or a curved surface, depending on the top shape of the syringe barrel.

[0018] Wherein, the groove 222 is square or arc-shaped, the inner diameter of the groove 222 is equal to the inner diameter d1 of the o-ring rubber plug 1, the width of the groove 222 is equal to the wire diameter d2 of the o-ring rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com