A jig for processing the outer wall of thin-walled sleeve parts without a through hole and its use method

A technology of thin-walled sleeves and parts, which is applied in the field of mechanical processing, can solve problems such as processing failure, reduced precision, and unstable clamping, and achieve the effects of reducing processing costs, improving production efficiency, and enhancing clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

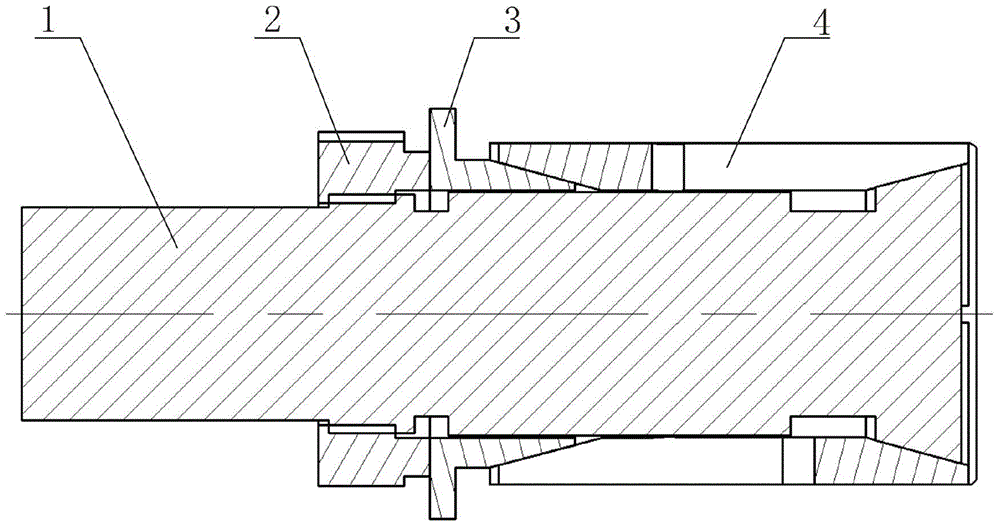

[0039] Embodiment: before use, need processing such as figure 1 For the parts shown in the figure, first use the three-jaw chuck on the lathe or grinder to clamp the upper clamping position of the mandrel 1, and calibrate the mandrel 1 so that the outer conical surface of the mandrel 1 is coaxial with the machine tool spindle.

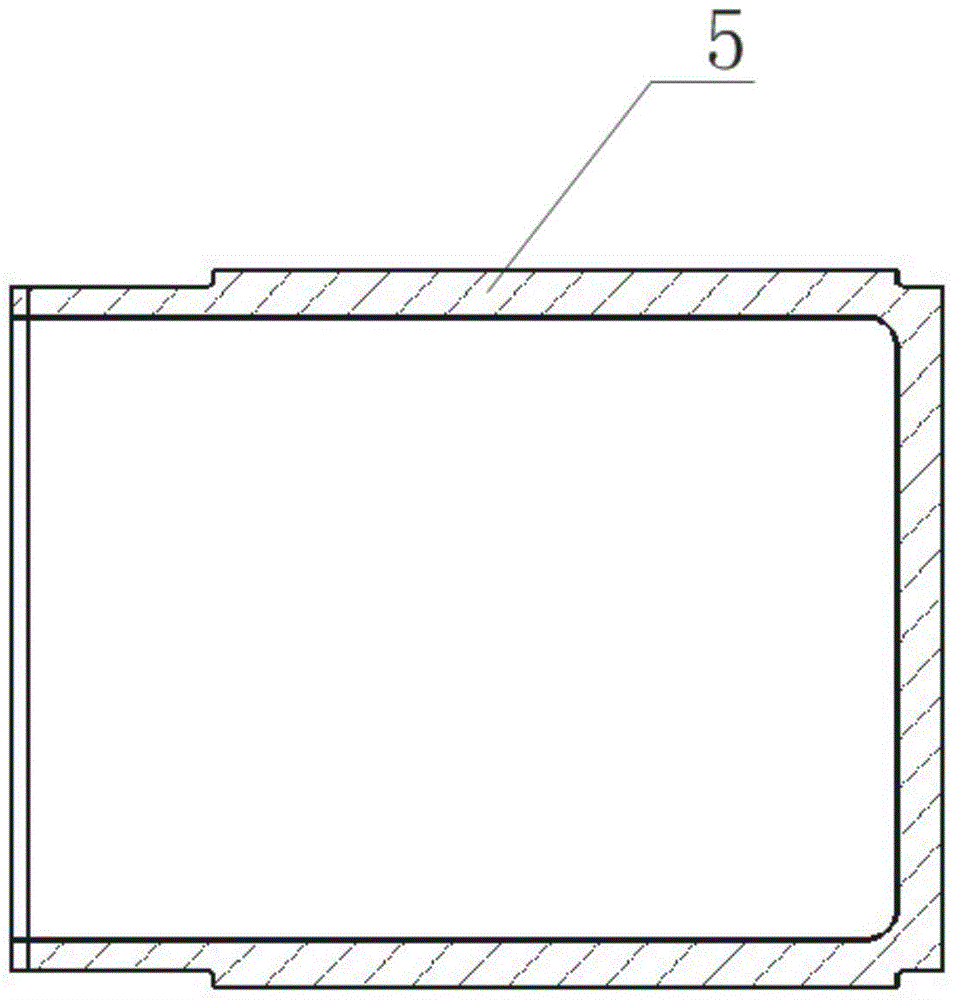

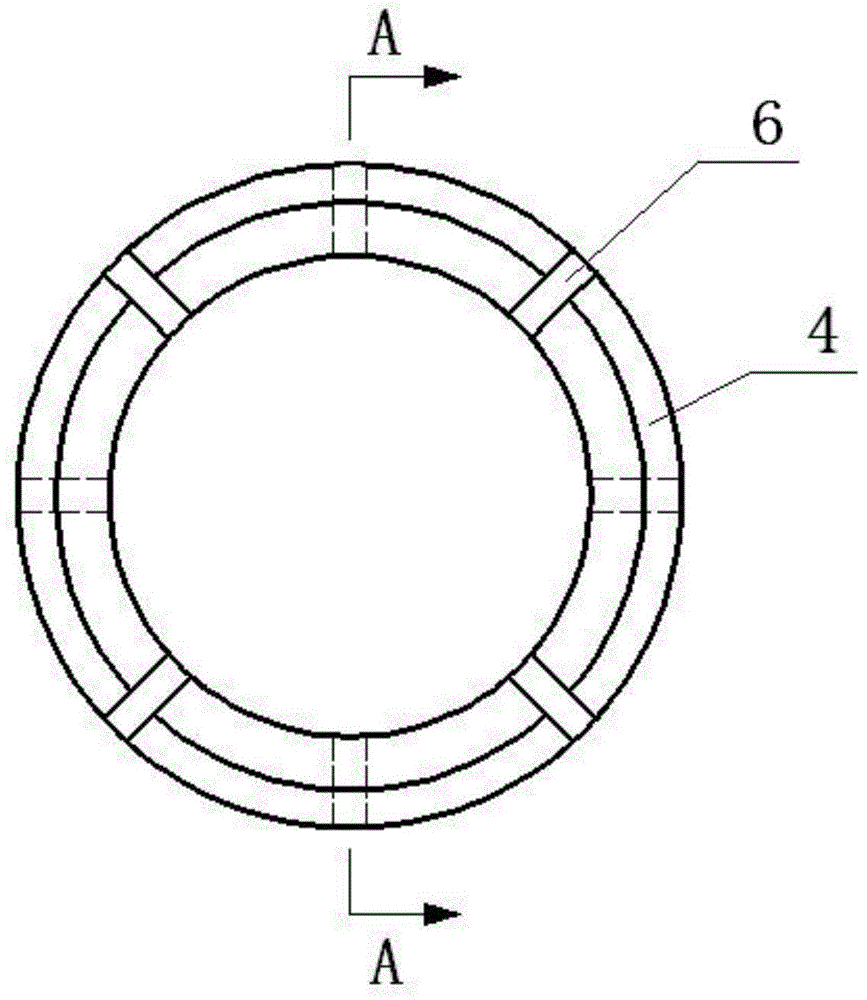

[0040] When used, it will be as figure 1 The opening of the part 5 shown is placed on the elastic collet 4 to the left and is as follows: Figure 5 In the state shown, make the inner bottom of the part 5 fit closely with the right end surface of the elastic collet 4, then turn the fastening nut 2 to the right to make the fastening nut 2 move axially to the right, and then push the taper sleeve 3 to Slide in the elastic jacket 4, and at the same time pull the end of the mandrel 1 to slide in the elastic jacket 4, due to the taper fit between the tapered sleeve 3 and the elastic jacket 4, the mandrel 1 and the elastic jacket taper fit, and the elastic j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com