A turntable structure and a crane with the turntable structure

A turntable and machine room technology, applied in cranes and other directions, can solve the problem of heavy turntable structure weight, and achieve the effects of weight reduction, lightweight design, and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

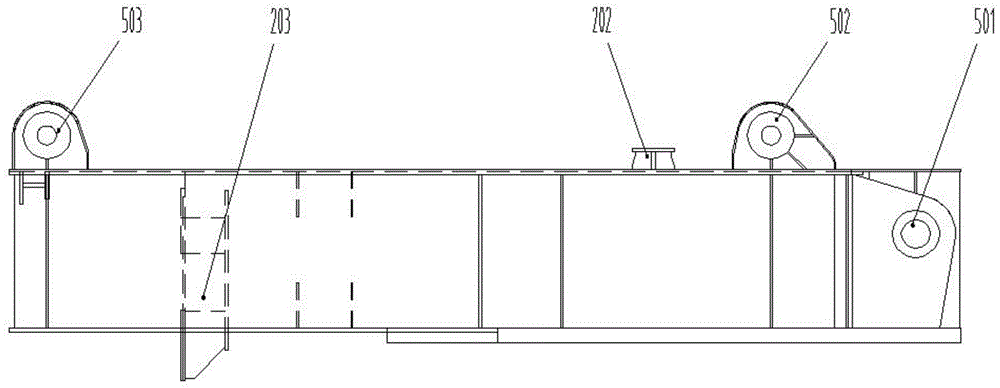

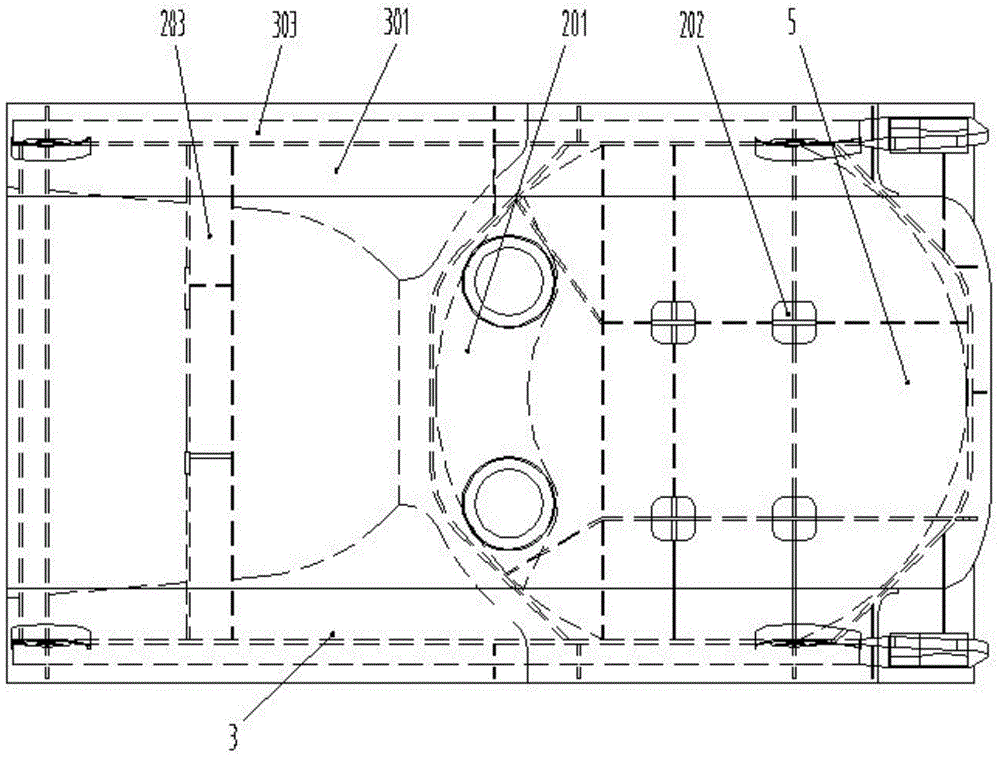

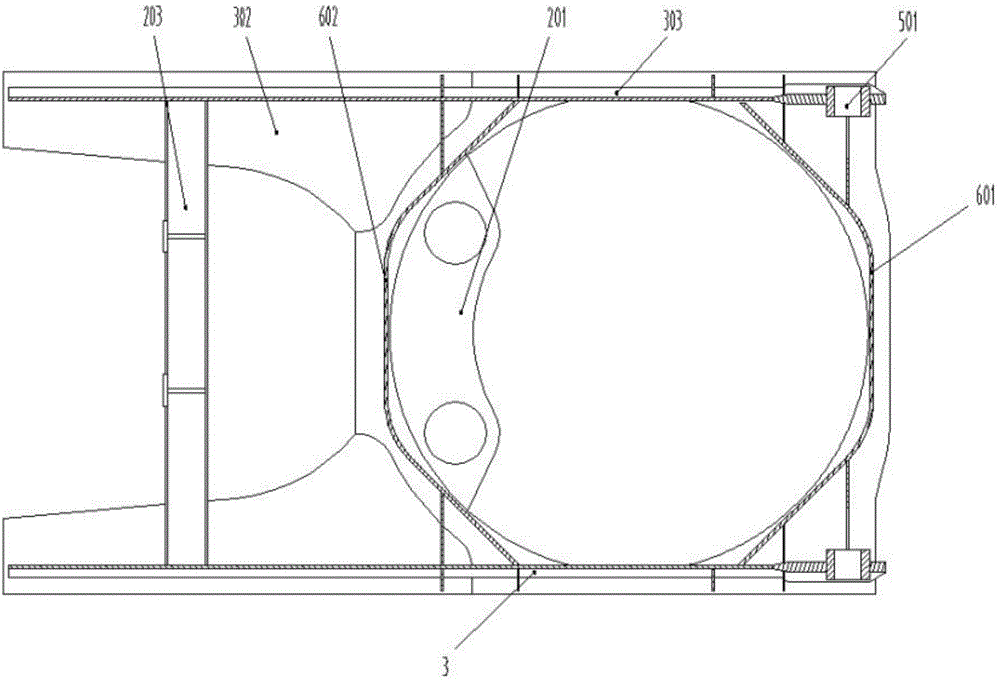

[0028] An embodiment of the present invention provides a turntable structure, such as Figure 1-3 As shown, the turntable structure includes a main body box 5 , and at least two I-beams 3 for fixing the A-frame 4 , a cylinder front plate 601 and a cylinder rear plate 602 are arranged inside the main body box 5 . to combine Figure 4 , the I-beam 3 includes an upper wing plate 301 and a lower wing plate 302 parallel to each other and a web 303 installed between the upper wing plate 301 and the lower wing plate 302, the upper wing plate 301 is connected with the main body box 5, and the web 303 The four legs 401 , 402 , 403 , 404 of the A-frame 4 are arranged in the main box 5 , that is to say, the web 303 and the upper wing 301 are arranged at an angle other than 90 degrees. Among them, the main body box 5 also includes a panel connected between the left and right upper wings 301 and a thick steel plate connected with the lower slewing bearing 7. The panel is relatively thin, ...

Embodiment 2

[0040] An embodiment of the present invention provides a crane, such as Figure 5 with Image 6 As shown, the crane includes the turntable structure 1 provided in the first embodiment, the A frame 4, the base column 8, the boom 11, the driver's cab 9, the machine room 10, the slewing mechanism and the luffing mechanism 13, the A frame 4, Base column 8 , boom 11 , driver's cab 9 , machine room 10 , slewing mechanism and luffing mechanism 13 are all arranged on the turntable structure 1 .

[0041] Wherein, the slewing mechanism includes: a slewing bearing 7 and a slewing reducer 14 , wherein the slewing reducer 14 is installed in the slewing reducer mounting support 201 . The second leg 402 and the third leg 403 of the A-frame 4 are located at the tail of the turntable structure 1, the first leg 401 and the fourth leg 404 of the A-frame 4 are located on the top surface of the head of the turntable structure 1, and the boom 11 The root is installed at the head of the turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com