Ammonium lignin sulphonate compound dust-proof agent and application thereof

A technology of ammonium lignosulfonate and ammonium lignosulfonate, which is applied in the field of ammonium lignosulfonate compound dustproof agent, can solve the problems of high cost, large water consumption, and not obvious dust removal effect, and achieve improved hydrophilicity The effect of improving mutual adsorption and reducing dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 25% ammonium lignosulfonate, 5% ethylene glycol and water are compounded according to weight percentage to form ammonium lignosulfonate compound dustproof agent. Then put the prepared ammonium lignosulfonate compound dustproof agent in the container for dilution, and the diluted use concentration is 5%.

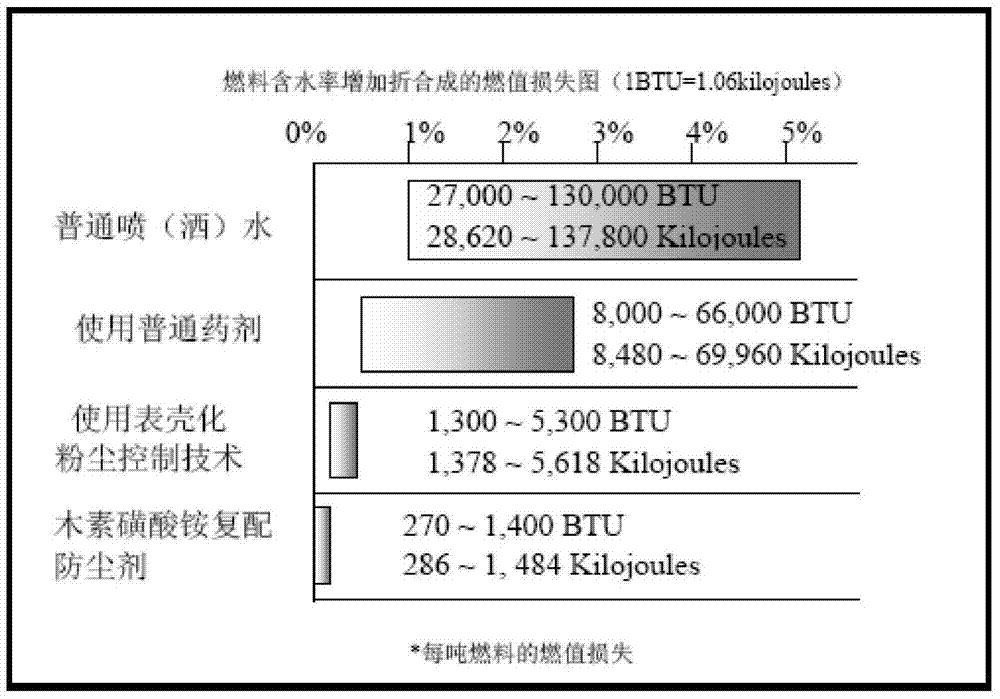

[0025] The diluted ammonium lignin sulfonate compound dustproof agent solution with a concentration of 5% is sprayed on the loose dust material through a high-pressure spray gun. The experimental results are as follows: figure 1 shown. It can be seen from the figure that spraying with ordinary water has poor effect, high moisture content, simple maintenance, but high cost. After adding common chemicals for spraying, the effect is good, the moisture content is significantly reduced, and the maintenance is simple, but the overall cost is high. Using the dustproof agent of the invention has good effect, lowest water content, simple maintenance and low cost.

[0026] Us...

Embodiment 2

[0028] 30% ammonium lignosulfonate, 10% ethylene glycol and water are compounded according to weight percentage to form ammonium lignosulfonate compound dustproof agent. Then place the prepared ammonium lignosulfonate compound dustproof agent in the container for dilution, and the diluted use concentration is 1%.

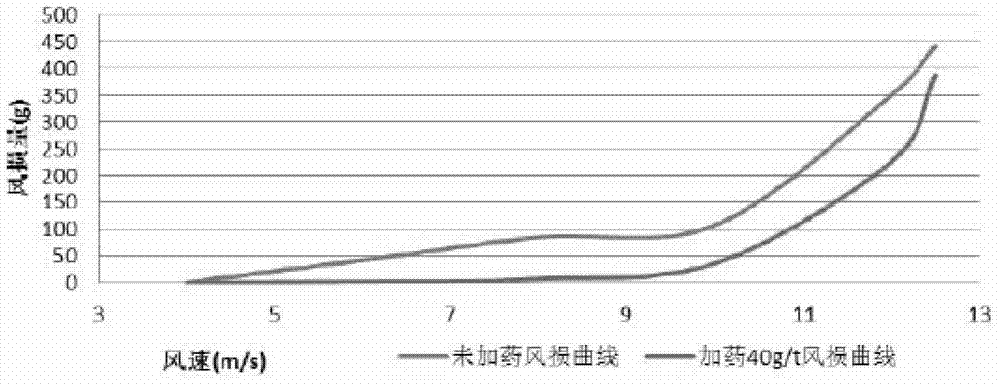

[0029] Use the diluted ammonium lignin sulfonate compound dustproof agent solution with a concentration of 1% to carry out dustproof treatment on loose dust materials by using a high-pressure spray water gun. The results are shown in Table 1 and Table 2 below through the detection of coal wind loss at a coal ore wharf in a certain port.

[0030] Table 1 Comparison table of effects before and after spraying

[0031]

[0032] The above experiments are comparisons carried out on a single coal stack. According to the experimental results, after spraying the first few transfer points with the ammonium lignosulfonate compound dustproof agent solution, the subsequent ...

Embodiment 3

[0037] 60% ammonium lignosulfonate, 15% ethylene glycol and water are compounded according to weight percentage to form ammonium lignosulfonate compound dustproof agent. Then place the prepared ammonium lignosulfonate compound dustproof agent in the container for dilution, and the diluted use concentration is 0.1%.

[0038] The diluted ammonium lignin sulfonate compound dustproof agent solution with a concentration of 0.1% was used for dustproof treatment and detection on the road surface of a mining area through a high-pressure water spray gun, and the results were as follows: image 3 shown.

[0039] The experimental results show that after spraying the ammonium lignosulfonate compound dustproof agent solution on the road surface, the dustproof water and power consumption are reduced by 30-50%, thereby reducing the dustproof cost and improving the environmental quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com