A rotating split riser tensioning ring

A riser, split-type technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of cumbersome connection and disassembly operations, complex structure, insufficient work efficiency and safety, and achieve convenience The effect of correct connection, flexible and convenient operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

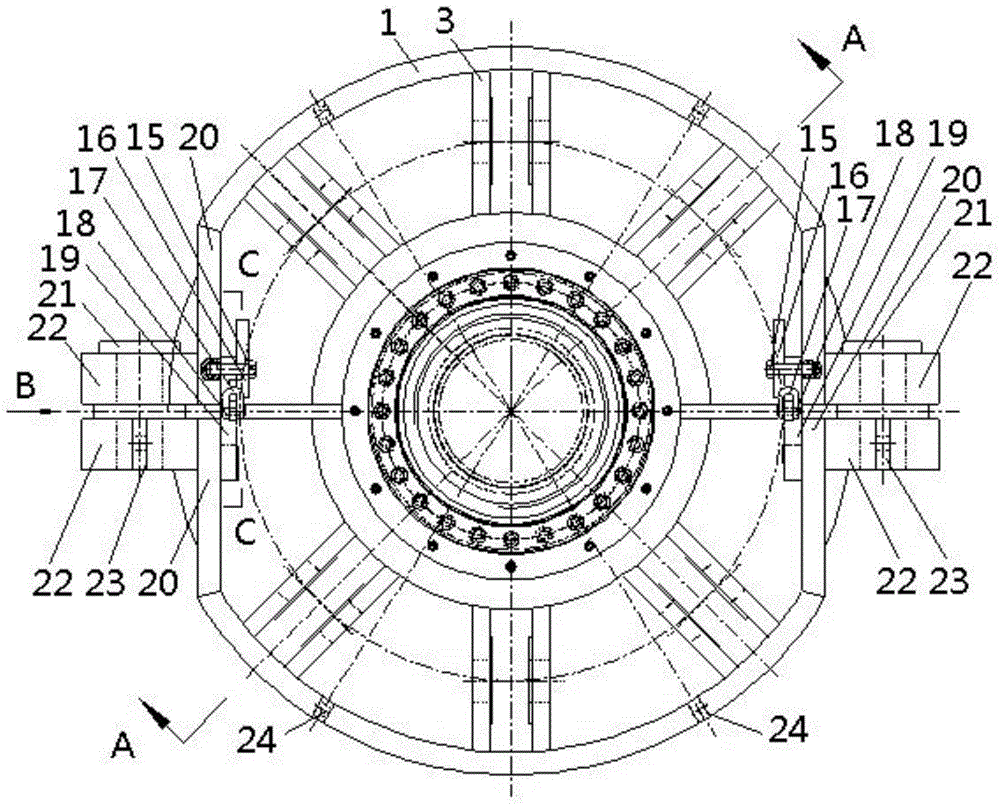

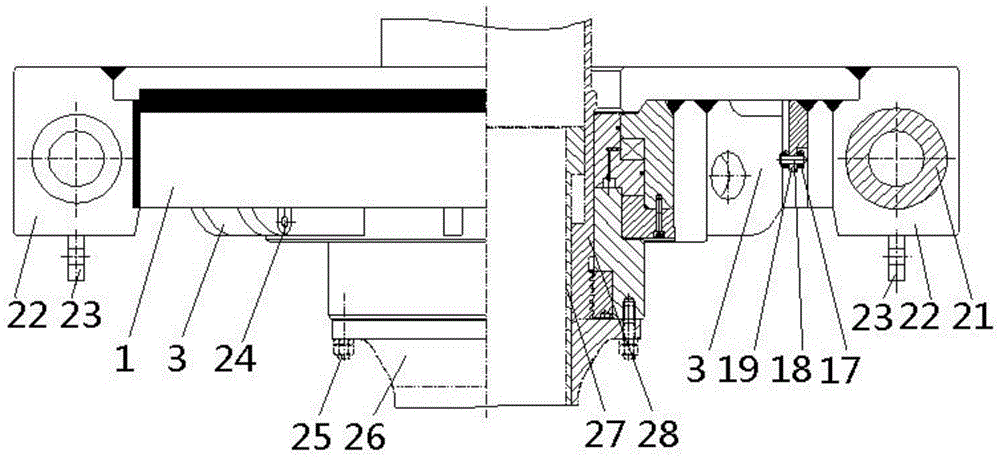

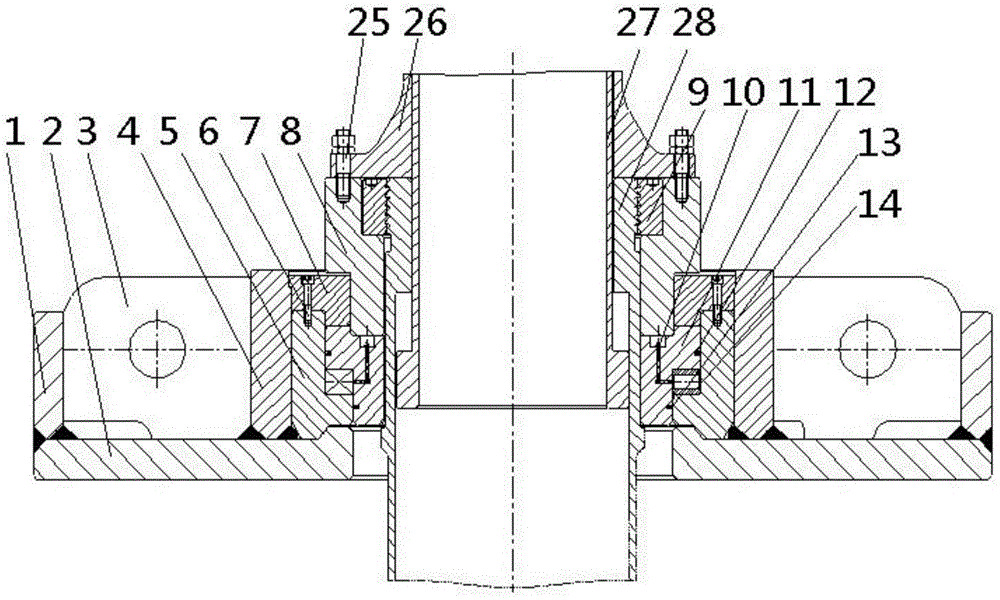

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The structure of the rotating type split riser tensioning ring of the present invention is that the riser tensioning ring is arranged as a symmetrical two-half structure,

[0028] refer to figure 1 and figure 2 , each half structure includes an outer peripheral vertical plate 1, an inner peripheral vertical plate 4, two vertical vertical plates 20 and multiple sets of wing plates 3 fixedly installed (welded) on the upper surface of the pressure-bearing bottom plate 2, wherein the outer peripheral vertical plate 1 and two The section of upright plate 20 is fixed (welded) on the outer periphery of pressure-bearing base plate 2, and the two sections of upright plate 20 are respectively located on the chord planes at both ends of the circumference of the outer peripheral vertical plate 1, and a plurality of lifting rings III 24 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com