Double-cavity hydraulic retarding device integrated at bottom of engine

A technology of retarder and hydraulic retarder, which is applied in the direction of mechanical equipment, brake type, liquid resistance brake, etc., to achieve the effect of improving low-speed performance, rapid warm-up or temperature increase, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

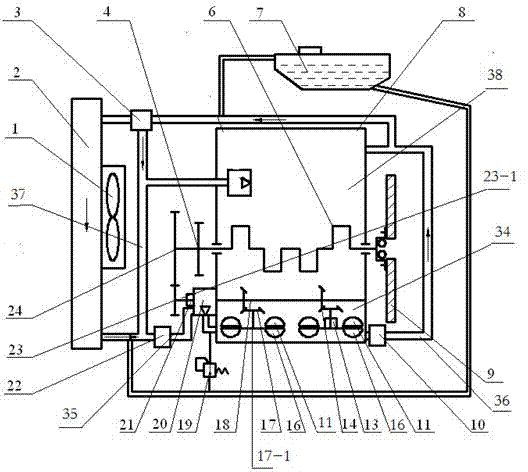

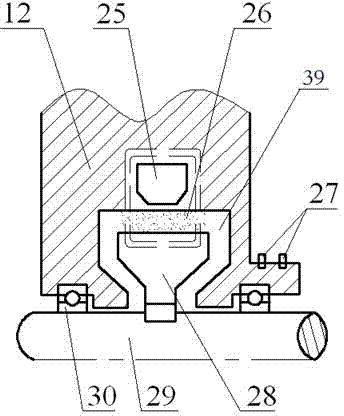

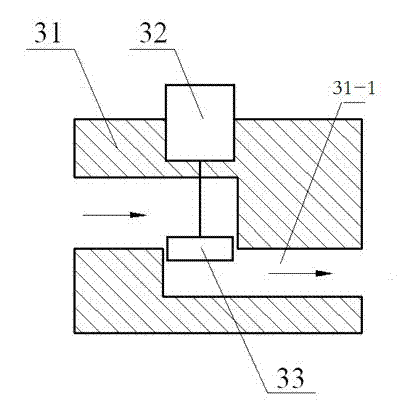

[0027] Such as Figure 1~3 As shown, a dual-chamber hydraulic retarder integrated at the bottom of the engine, including a hydraulic retarder and a control unit, the hydraulic retarder is installed at the bottom of the engine 8, and the hydraulic retarder has retarding work Cavity 34, which also includes centralized output shaft 18, inlet pipe 35, outlet pipe 36, pump 20, return pipe 37 and inlet throttle valve 22 for controlling the flow of coolant in the inlet pipe 35 and controlling the flow of coolant in the outlet pipe 36 A large amount of outlet throttle valve 10, the hydraulic retarder has at least two sets of moving wheel and fixed wheel devices and is arranged in the retarder working chamber 34, each set of moving wheel and fixed wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com