Gas stove timing pulse controller and gas stove adopting pulse controller

A technology of pulse controller and timing pulse, which is applied in applications, household heating, heating fuel, etc., can solve the problems of increasing costs and reducing versatility, and achieve the effects of increasing selling points, improving cost performance, and improving safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

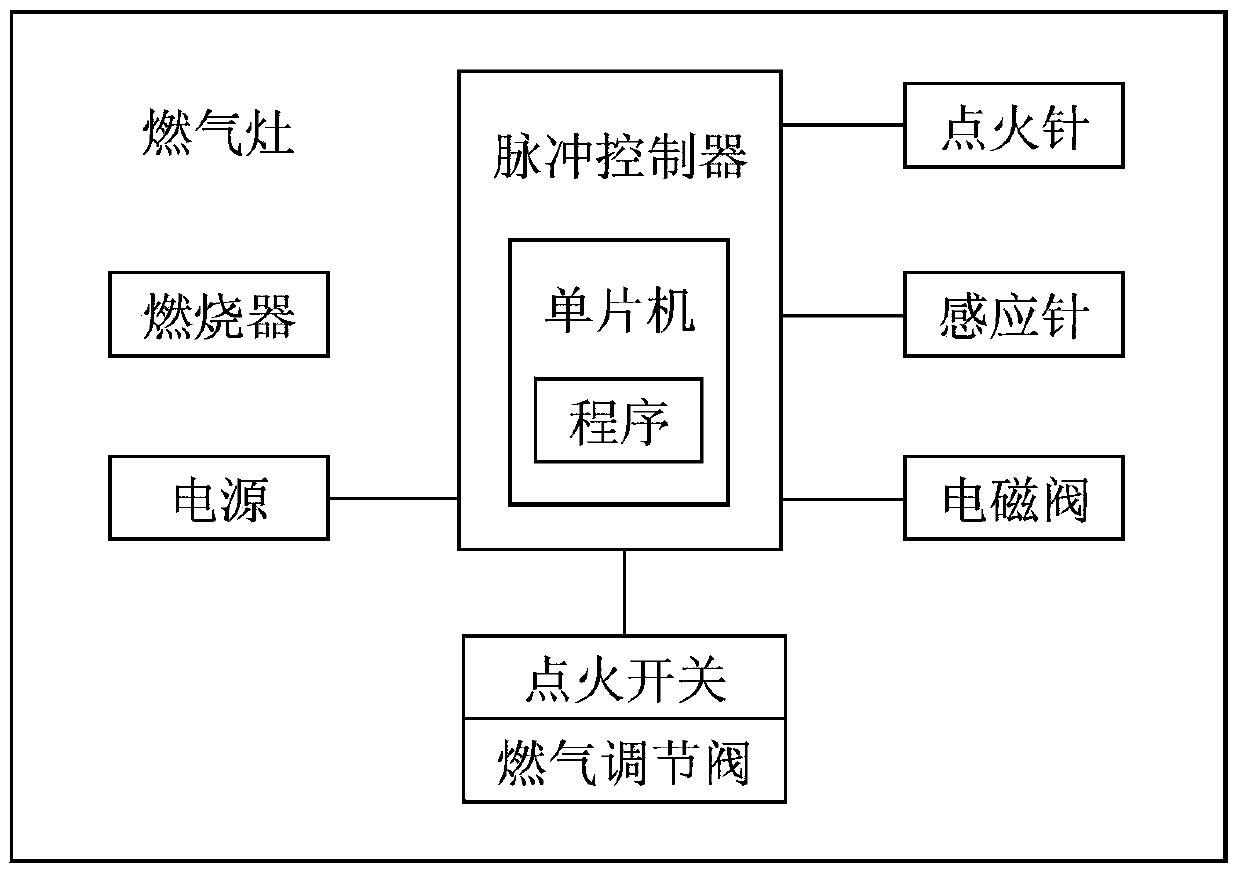

[0023] see figure 1 . A gas stove adopting the timing pulse controller of the present invention mainly includes a pulse controller, an ignition needle, an induction needle, a gas regulating valve, an ignition switch on the gas regulating valve, a solenoid valve, a power supply, a burner and a panel, etc. . The pulse controller mainly includes a single-chip microcomputer, an ignition high-voltage circuit, a flame detection circuit, a solenoid valve drive circuit, a sound prompt circuit, an ignition switch input circuit, a power supply circuit, and the like. The pulse controller is connected with the ignition needle, the induction needle, the ignition switch, the electromagnetic valve and the power supply. The hardware and structure of the above-mentioned timing pulse controller and the gas cooker adopting the pulse controller are no different from the common pulse controller and gas cooker. The feature of the timing pulse controller is that the software of the original pulse...

Embodiment 2

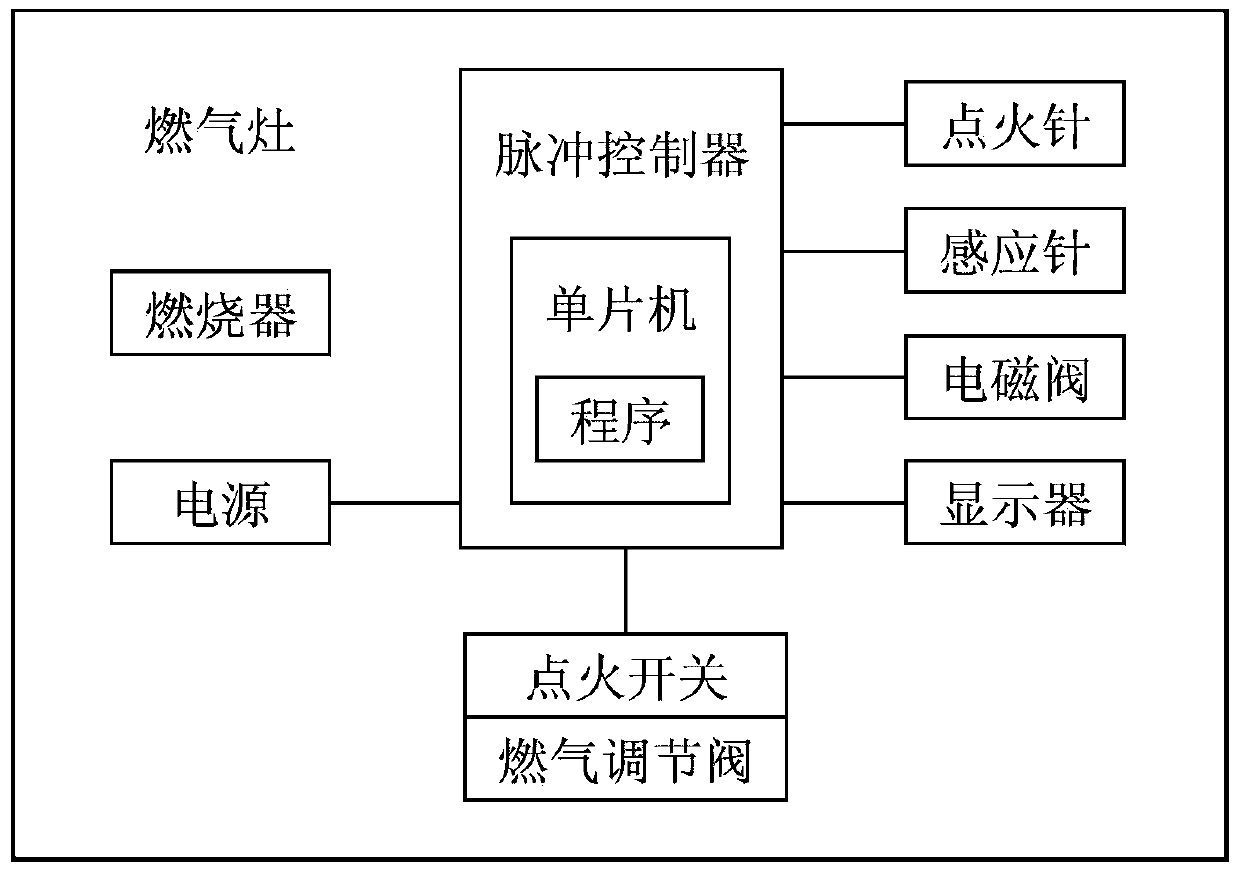

[0025] see figure 2 . Based on Embodiment 1, it is characterized in that there is a display driver in the single-chip microcomputer program of the pulse controller and a time display for timing flameout is added on the gas cooker panel.

Embodiment 3

[0027] see figure 1 with figure 2 . Based on Embodiment 1 or 2, it is characterized in that by pressing the knob of the original gas regulating valve, the ignition switch contact on the original gas regulating valve outputs an on-off signal to the single-chip microcomputer of the pulse controller, thereby realizing the timing extinguishment of the gas stove Manual adjustment of time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com