Method and device for calibrating optically biaxial return and gas bath type angular displacement laser interferometer

A laser interferometer, laser interference technology, applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve the effect of small Abbe error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

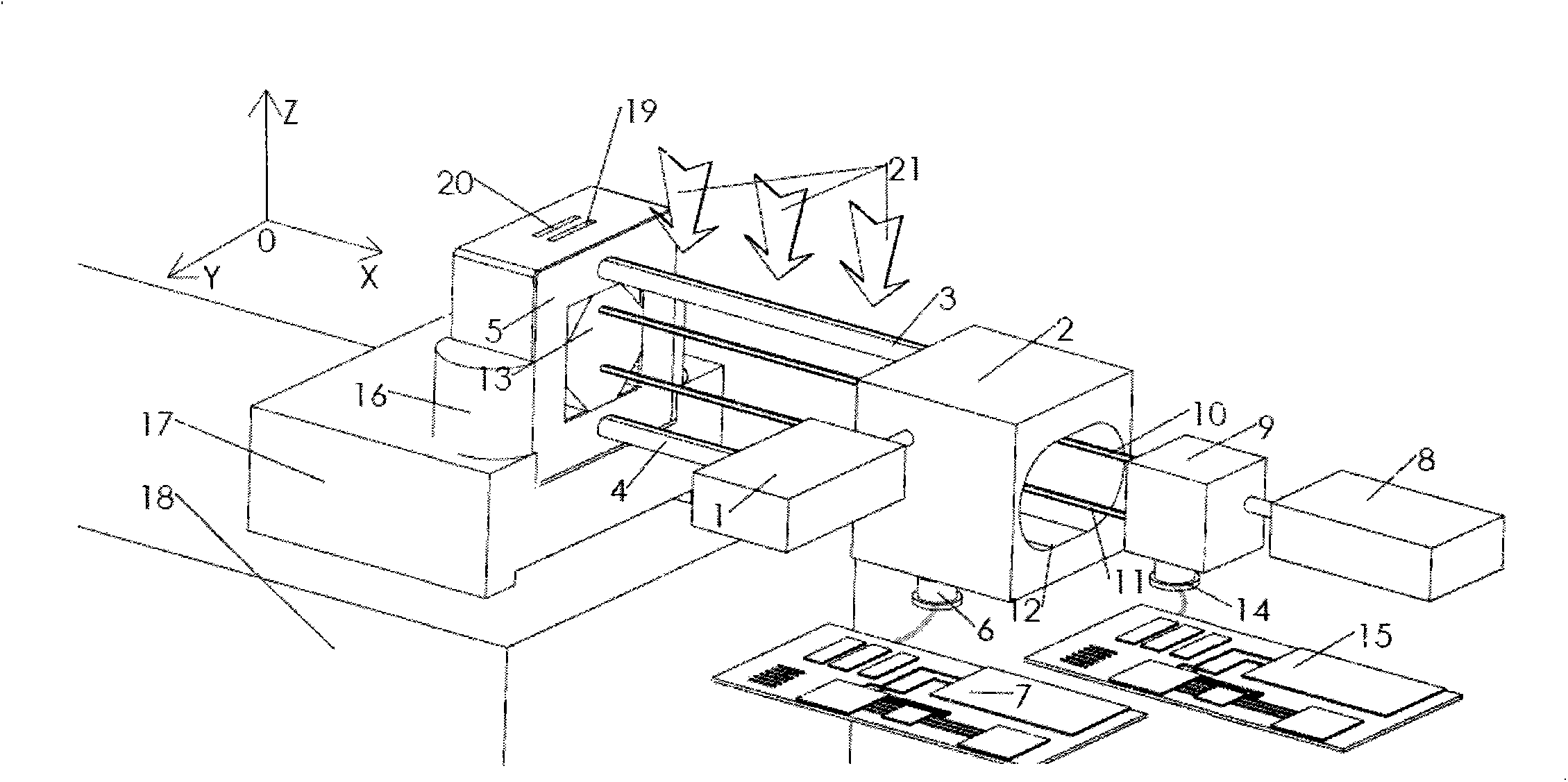

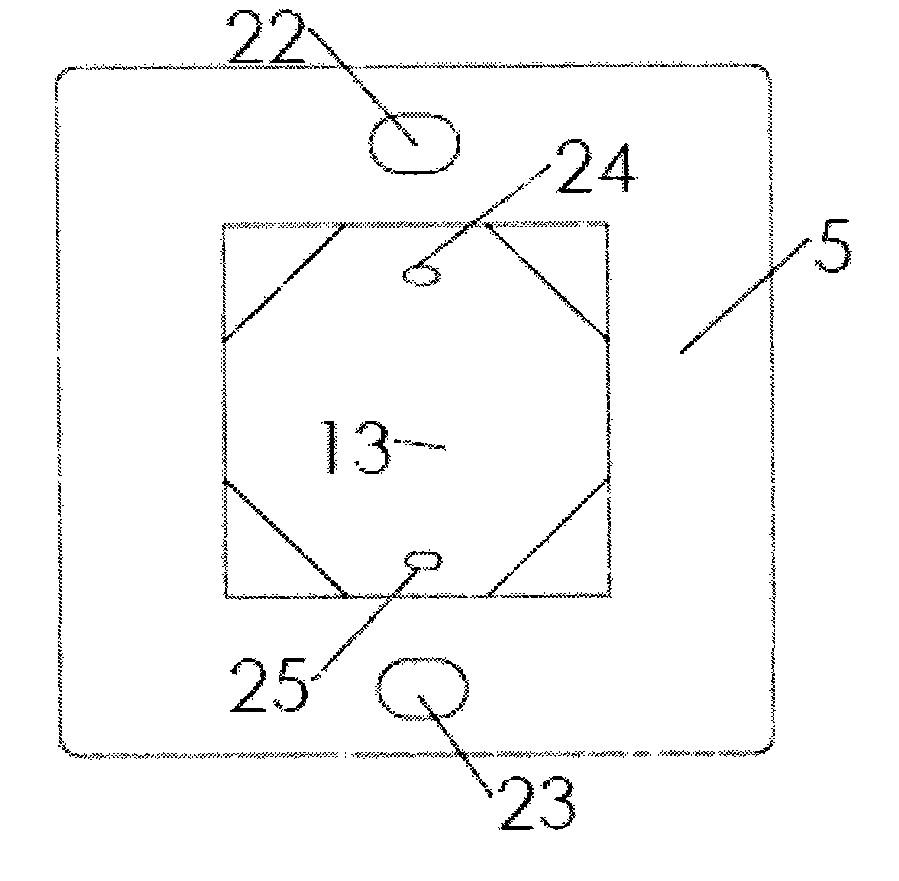

[0022]A dual-optical axis return and air bath angular displacement laser interferometer calibration device, including a standard laser interferometer laser 1, a receiver 6 at the position that can receive the interference signal of the standard laser interferometer, and a wire that connects the receiver 6 to the standard laser The interferometer signal processing system 7 is connected; on the output optical path of the standard laser interferometer laser 1, there is a dual-axis hollow standard laser interferometer group 2 that can allow the calibrated laser interferometer measurement beams 10, 11 to pass through the middle through hole 12; The guide rail 18 is arranged on one side of the two-axis hollow standard laser interference mirror group 2, and the moving table 17 is fitted on the guide rail 18. The plane mirror 5 with the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com