A method for correcting the absolute displacement of the endpoint of a vacuum laser alignment displacement measurement device

A technology of absolute displacement and displacement measurement, which is applied in measuring devices, optical devices, instruments, etc., can solve problems such as difficulty, and achieve the effect of saving engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

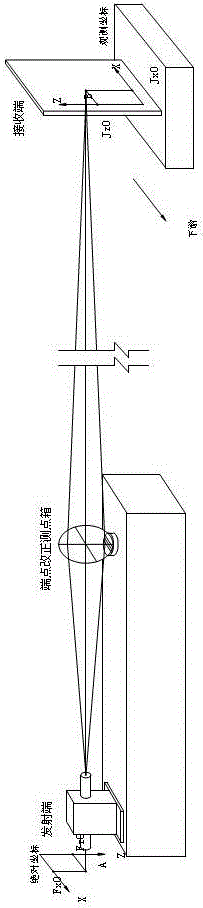

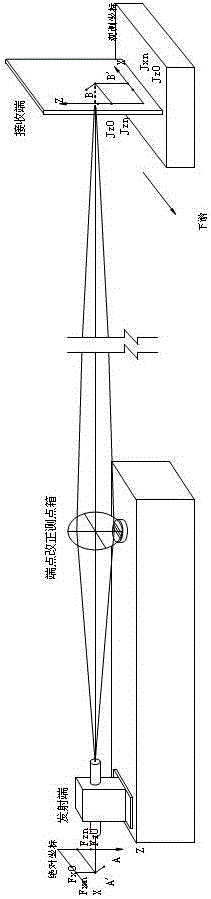

[0034] Include the following steps:

[0035] (1) Install either the transmitting end device or the receiving end device in a stable position. If the position is unstable, an absolute displacement measuring device for the end point must be installed;

[0036] (2) Install a measuring point box for displacement correction of the other end point within 5-20m from the end point. The measuring point box and the end point equipment are required to be installed on the same platform or ensure that the position of the calibration device is accompanied by the end point Simultaneous deformation;

[0037] (3) Calculate the relative displacement change between the receiving end and the transmitting end by measuring the displacement change of the position of the measuring point box, and calculate the relative displacement change between the receiving end and the transmitting end through the end point correction calculation method. The relative displacement change plus the absolute displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com