Device and method for automatically calibrating performance parameters of CCD (Charge Coupled Device)

An automatic calibration and parameter technology, which is applied in the direction of testing optical performance, can solve the problems of difficulty in ensuring repeatability and test accuracy, inability to realize automatic testing, and lack of unified control, so as to avoid unstable factors, avoid errors, and improve confidence degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

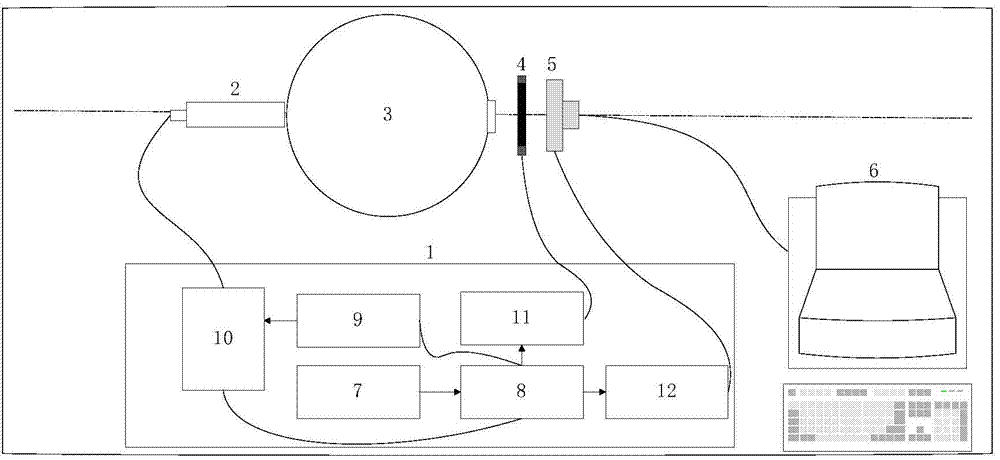

[0038] Such as figure 1 As shown, the present invention is composed of a control module 1 , a pulsed laser 2 , an integrating sphere 3 , a mechanical shutter 4 , a tested CCD detector 5 and a main control computer 6 . Among them, the control module 1 is composed of a clock pulse generation circuit 7 , an automatic pulse width adjustment circuit 8 , an output pulse driving capability amplification circuit 9 , a power module 10 , a shutter control circuit 11 and a CCD trigger signal output circuit 12 . The specific working process is as follows:

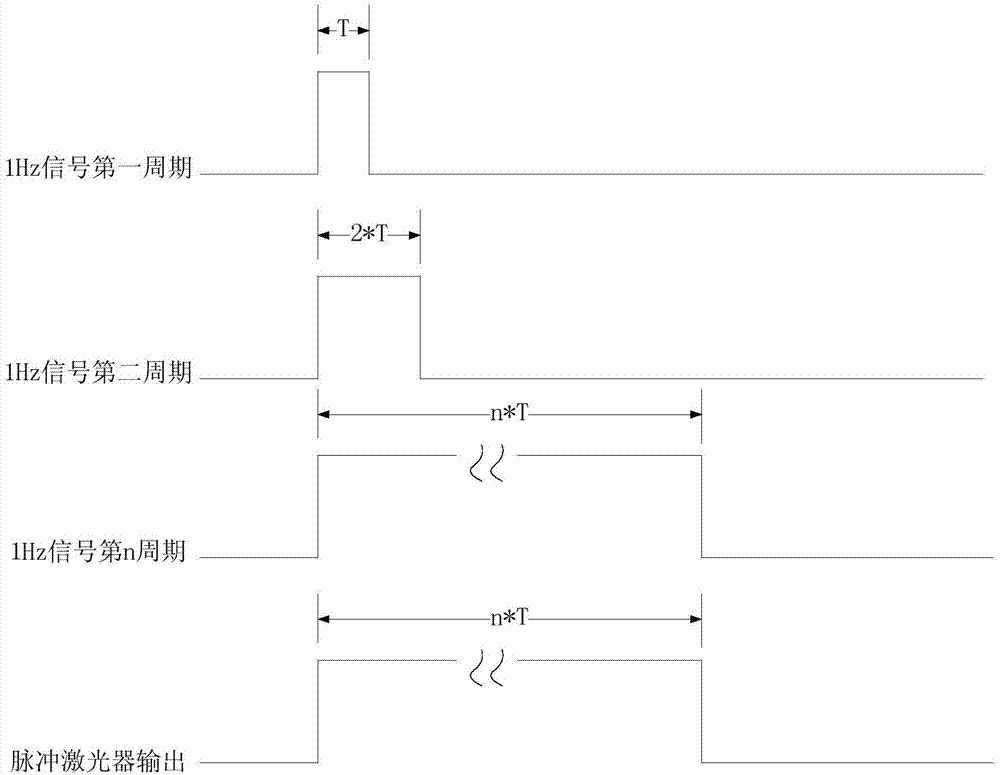

[0039](1) The pulse laser output pulse excitation period is T, and a clock signal with a frequency of 1 Hz is generated by a clock pulse generation circuit. Set the initial pulse width to the pulse laser output pulse excitation period, and its frequency stability is -9 , frequency accuracy -7 .

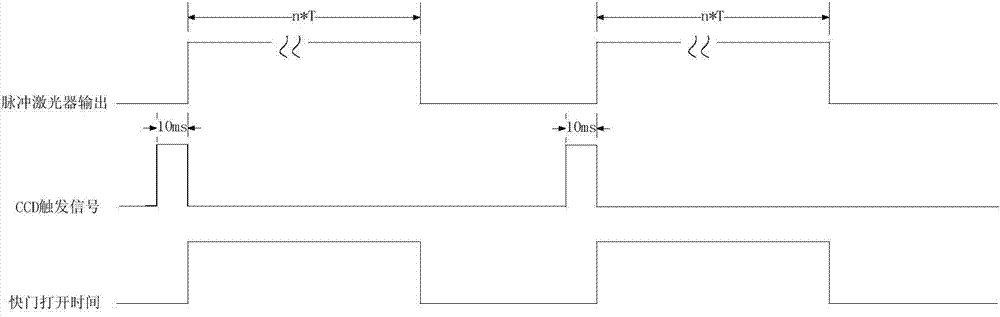

[0040] (2) 2s before the automatic test starts, the CCD trigger signal output circuit triggers the CCD exposure, and the image data at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com