OLED (organic light-emitting diode) display screen, manufacturing method for same and display device

A technology for display screens and substrates, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, electrical components, etc., can solve problems that affect production efficiency and product quality, and achieve improved production efficiency and product quality, large process error range, The effect of reducing the difficulty of debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

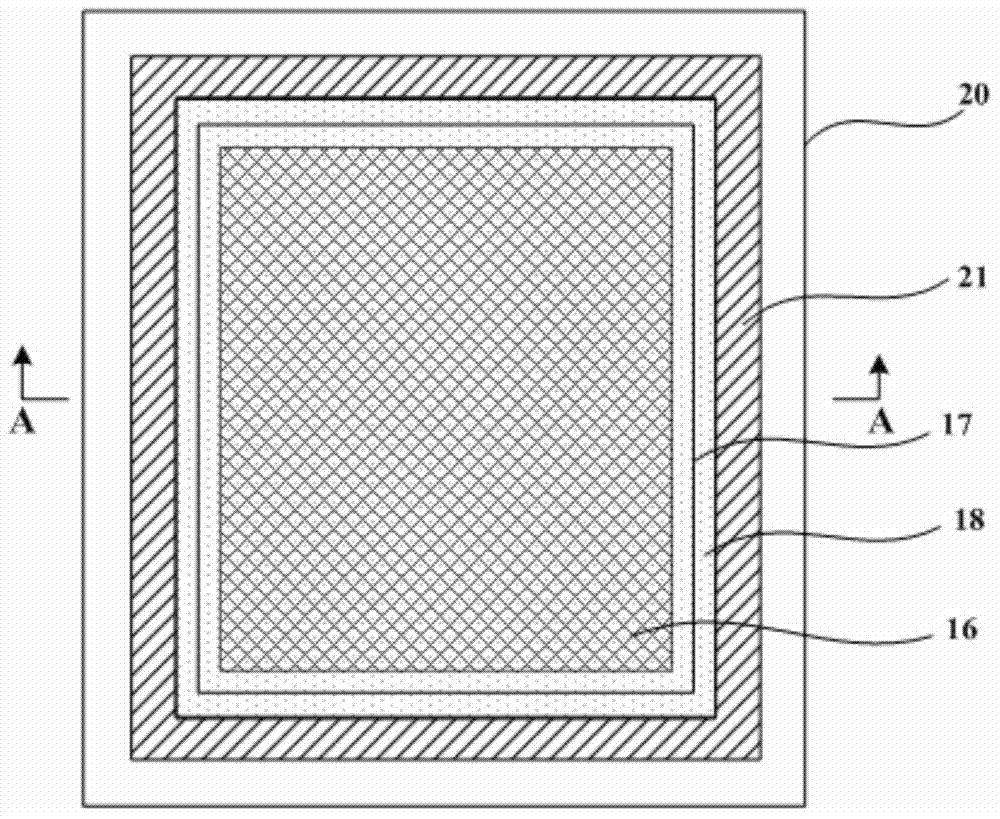

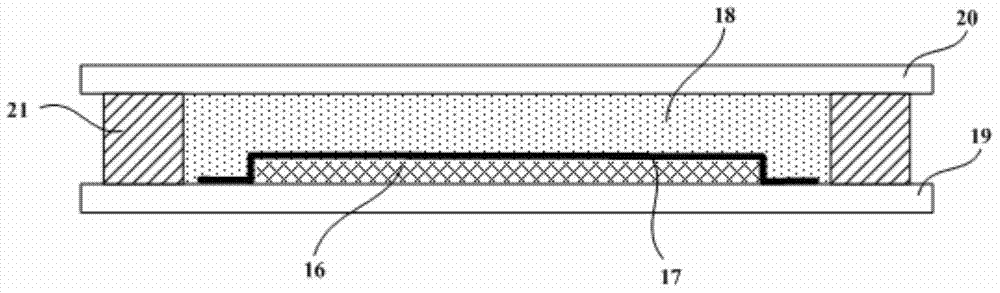

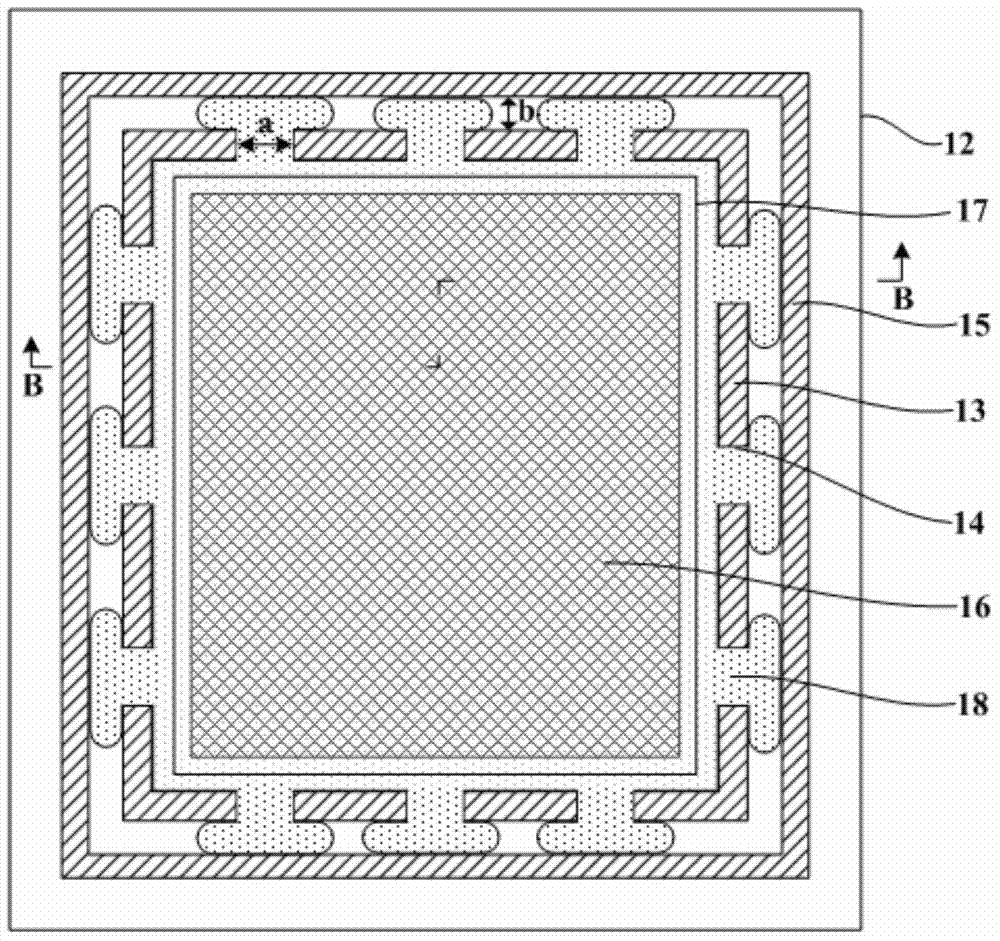

[0037] In order to reduce the difficulty of debugging the OLED display production process and improve the production efficiency and product quality of the product, embodiments of the present invention provide an OLED display, a manufacturing method of the OLED display, and a display device. In the technical solution of the OLED display screen of the present invention, two inner and outer dam glues are provided. The filler only needs to fill the inner area of the first dam glue, and the excess filler can be removed from at least one opening of the first dam glue. It flows out and fills the gap area between the first dam glue and the second dam glue. With this design, the filling amount of the filler has a larger process error range compared with the prior art, and therefore, greatly reduces the OLED The difficulty of debugging the display screen production process is conducive to improving the production efficiency and product quality of the product. In order to make the objec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com