IGBT (Insulated Gate Bipolar Transistor) driving circuit

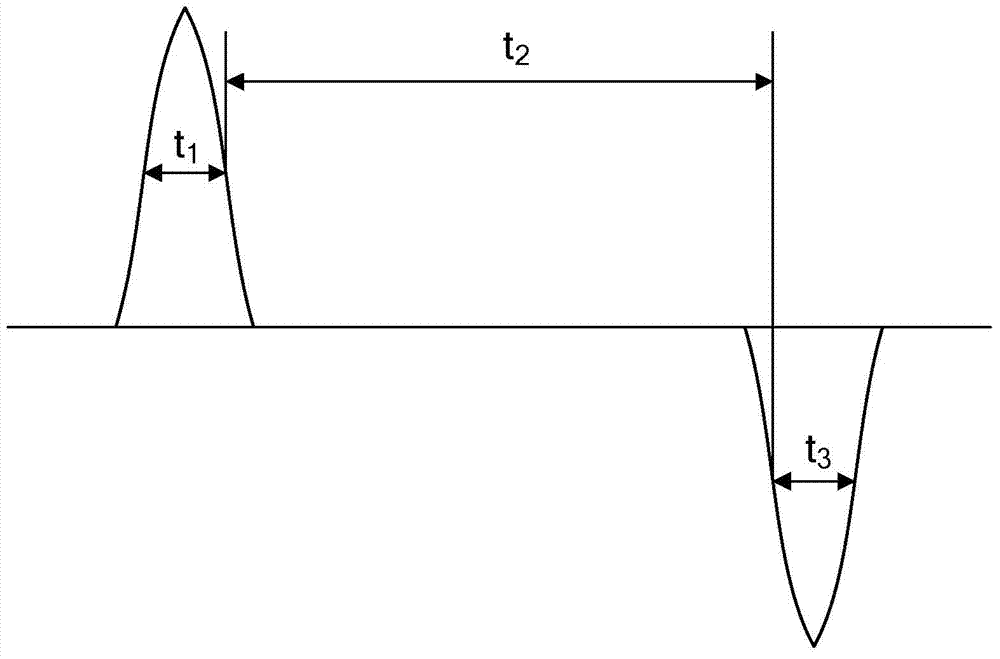

A technology for driving circuits and freewheeling circuits, which is applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of limited application range of IGBT series technology and short turn-on time of driving signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

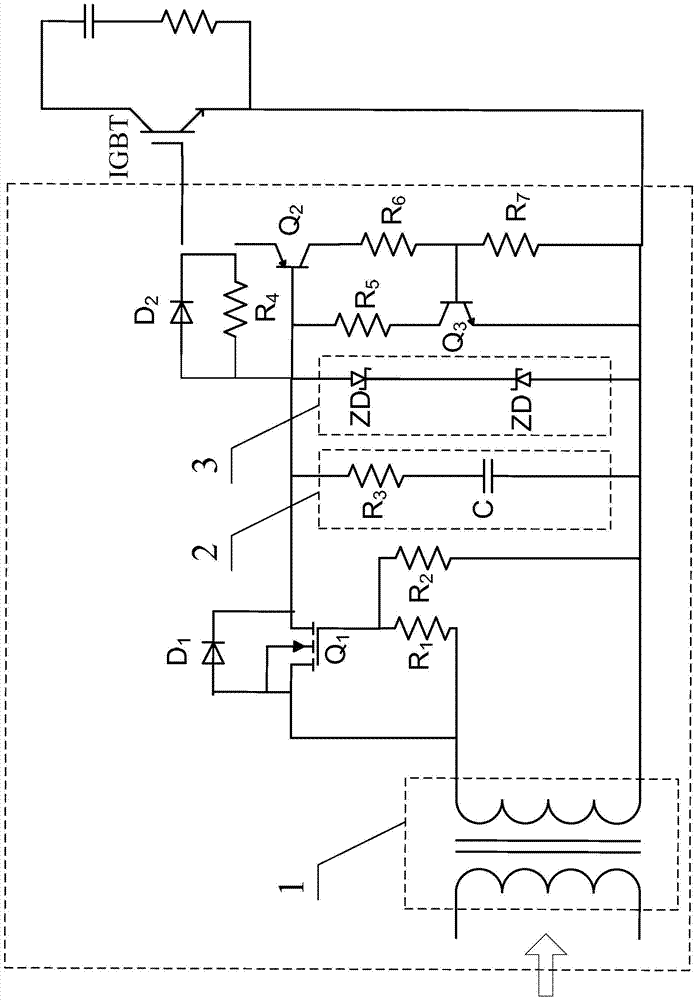

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of IGBT driving circuit described in this embodiment mode comprises ferrite bead 1, is characterized in that: it also comprises P-type MOSFET Q 1 , the first triode Q 2 , the second triode Q 3 , the first diode D 1 , the second diode D 2 , freewheeling circuit 2, voltage stabilizing circuit 3, first resistor R 1 , the second resistor R 2 , the fourth resistor R 4 , the fifth resistor R 5 , the sixth resistance R 6 and the seventh resistor R 7 , one terminal of the output end of the ferrite bead 1 is simultaneously connected to the first diode D 1 positive electrode, P-type MOSFET Q 1 source and the first resistor R 1 One end of the first resistor R 1 The other end is connected to the P-type MOSFET Q 1 gate, the first resistor R 1 with P-type MOSFET Q 1 The common terminal is connected to the second resistor R 2 One end of the freewheeling circuit 2 and the voltage st...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1This embodiment is described. This embodiment is a further limitation of the IGBT drive circuit described in Embodiment 1. In this embodiment, the freewheeling circuit 2 is composed of a third resistor R 3 connected in series with capacitor C.

[0017] The energy storage and discharge functions of the freewheeling circuit 2 are realized by the capacitor C.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the IGBT drive circuit described in Embodiment 1. In this embodiment, the voltage stabilizing circuit 3 is composed of two Zener diodes in series, and the two Zener diodes connected to the positive pole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com