Aerial fog diffuser and production method

A disperser and aerosol technology, which is applied in the field of nano-scale aerosol dispersers, can solve the problems of increasing oxygen machine requirements and high pressure, and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

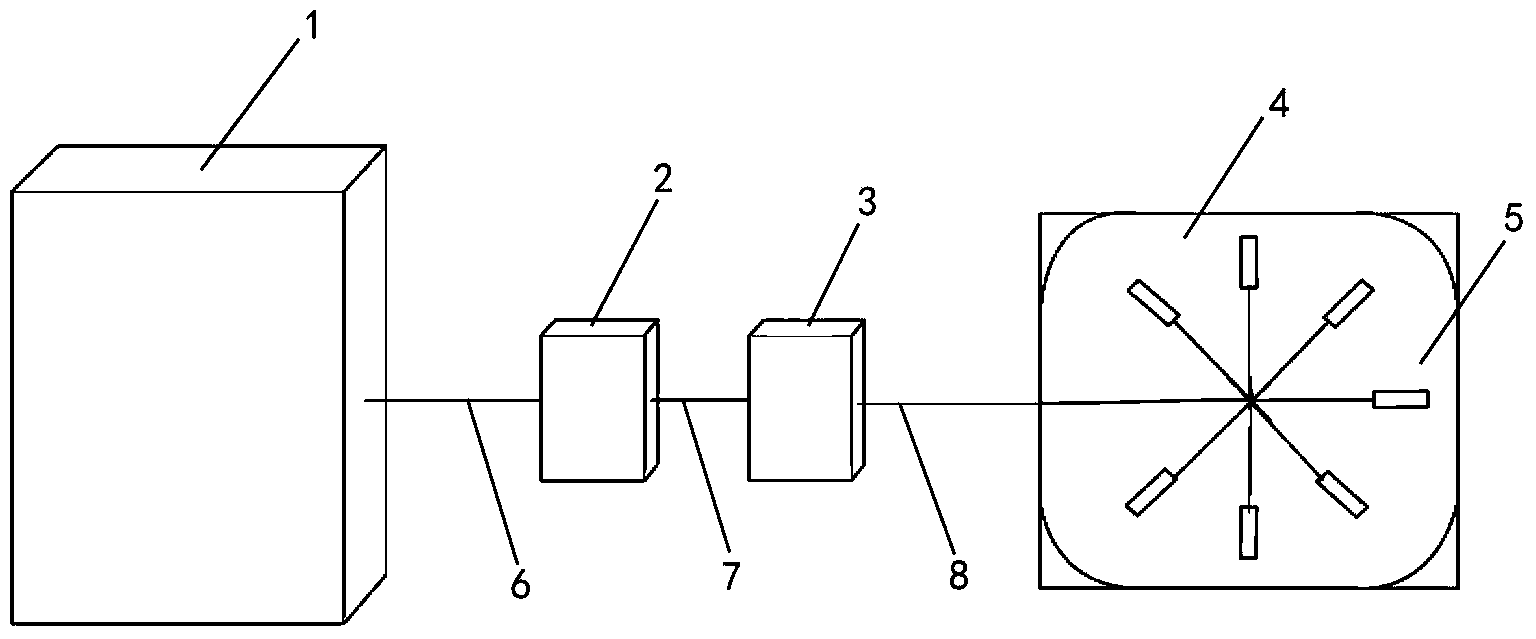

[0034] The present invention is applied to an underwater aerosol generation system, and the system includes a gas source station 1, a first-level control device 2, a second-level control device 3, a pool 4, an aerosol pipe network, and pipelines 6, 7, and 8. The aerosol pipe network is composed of a plurality of aerosol dispersers arranged in various ways.

[0035] The main components of the system are described in detail below:

[0036] 1. Air source station: Air source station 1 supplies air or oxygen in various ways.

[0037] The first way: Air compressor supply air. Oil-free air compressor 1 is used, and then the temperature is lowered by the air refrigerator of the first-stage control device, and then the clean cold air with a certain pressure and temperature is input through the pipeline through the second-stage control device including filters and other devices. The aerosol in the pool produces a pipe network, and then produces ultra-fine bubbles through the micro-nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com