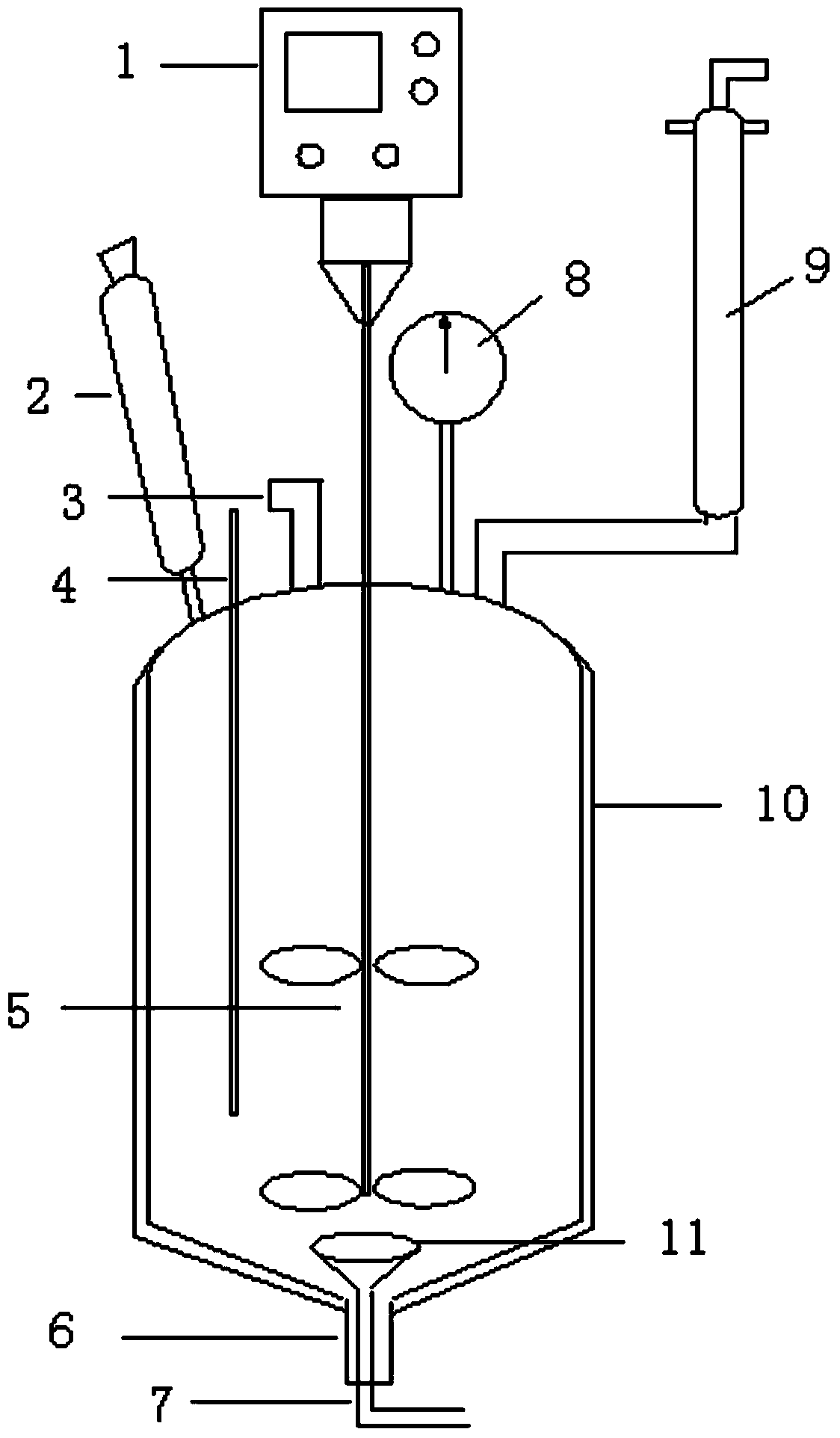

Uniform aerating double-layered glass reaction kettle

A double-layer glass, reaction kettle technology, applied in the field of reaction kettles, can solve the problems of small gas-liquid, gas-solid contact area, affecting the production efficiency of the reaction kettle, increasing production risks, etc. The effect of receptivity and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

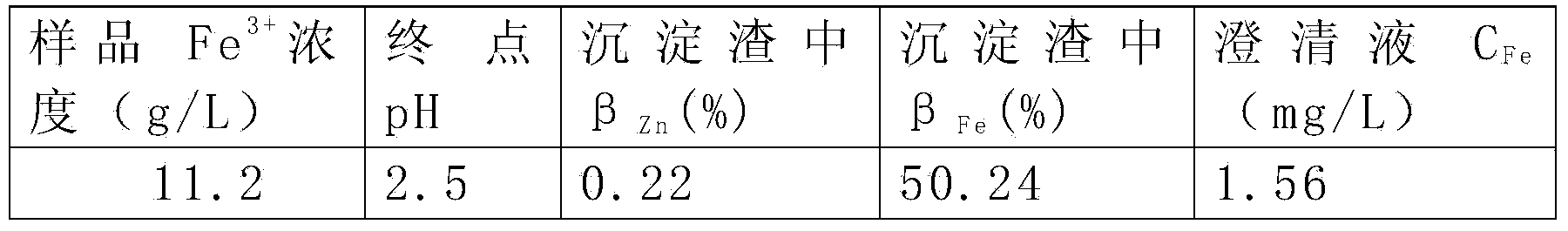

Embodiment 1

[0015] A 50L uniformly aerated double-layer glass reactor was used as the reaction vessel for the iron removal experiment of the zinc sulfate leaching solution. The zinc sulfate leaching solution contains 11.2g / L of ferrous iron, and the leaching solution is sprayed into the reactor from the feed port, and the inflatable disc is 1m 3 The rate of / h is evenly aerated, and at the same time, the neutralizing agent sodium carbonate is added at a certain speed to ensure that the pH of the solution in the reactor is maintained at 2-3, and the reaction temperature is 80-90°C. After the reaction is over, open the discharge valve, discharge the feed liquid under the gas pressure in the kettle, and obtain the purified iron removal liquid and iron slag after filtration.

[0016] Test results of iron removal by zinc sulfate solution

[0017]

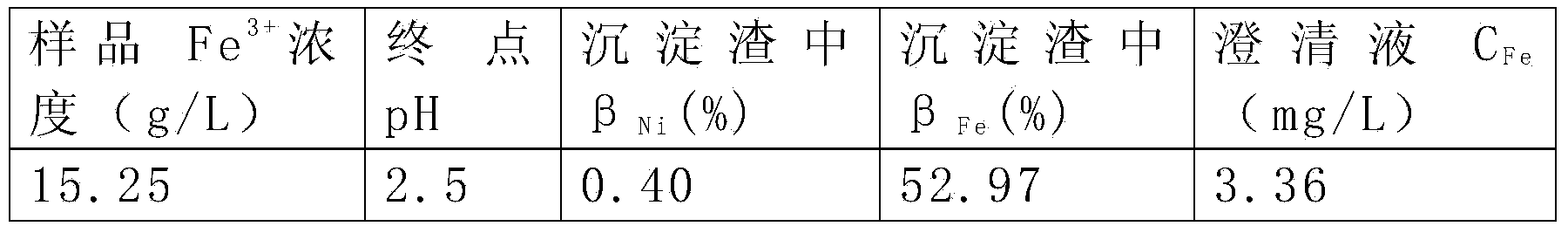

Embodiment 2

[0019] A 50L evenly aerated double-layer glass reactor was used as the experimental reaction vessel for the iron removal experiment of the nickel sulfate leaching solution. The nickel sulfate leaching solution contains 15.25g / L of ferrous iron, and the leaching solution is sprayed into the reactor from the feed port, and the inflatable plate is 1m 3 The rate of / h is evenly aerated, and at the same time, the neutralizing agent sodium carbonate is added at a certain speed to ensure that the pH of the solution in the reactor is maintained at 2-3, and the reaction temperature is 80-90°C. After the reaction is over, open the discharge valve, discharge the feed liquid under the gas pressure in the kettle, and obtain the purified iron removal liquid and iron slag after filtration.

[0020] Iron removal test results of nickel sulfate leaching solution

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com