Post-treatment method for desulphurization slag

A technology for desulfurization slag and crushed slag, applied in the field of comprehensive utilization of resources, can solve the problems of high production cost, low utilization rate of desulfurization slag, and inability to fully separate, and achieves the effect of cost saving and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

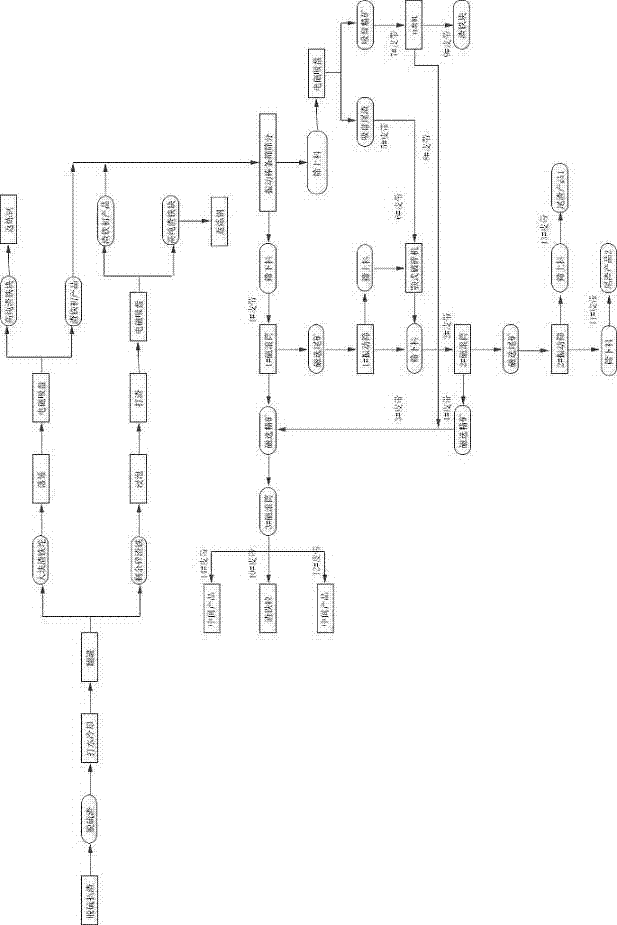

[0027] Such as figure 1 As shown, a post-treatment method for desulfurization slag includes the following steps:

[0028] (1) Cool the hot desulfurization slag, turn over the tank, and separate to obtain lump slag and broken slag;

[0029] (2) The slag is subjected to drop hammer treatment, and then screened with an electromagnetic chuck to obtain high-purity slag iron nuggets and slag iron preliminary products;

[0030] (3) Put the slag obtained in step (1) into a soaking tank equipped with industrial circulating water and soak for more than 4 hours. The soaked slag is slag treated, and the slag is screened by an electromagnetic chuck. Obtain high-purity slag iron nuggets and initial slag iron products;

[0031] (4) The primary slag iron product obtained in step (2) and step (3) is sieved through a vibrating rod sieve with a sieve aperture of 100×100 mm, and the oversize material and undersize material are separated;

[0032] (5) Flatten the screened material obtained in step (4), sc...

Embodiment 2

[0043] After desulfurization and slag removal in the steelmaking process, the hot desulfurization slag generated by the slag removal is quenched and cooled by water, and then the desulfurization slag is transported to the drop hammer workshop with a tank truck for tank turning, and large slag iron lumps are used with a forklift. It is pushed into the drop hammer pit to drop the hammer, and then the slag iron with the dropped hammer is magnetically separated by the electromagnetic chuck to obtain high-purity slag iron for steelmaking. The remaining broken slag iron is transferred to the soaking tank with a forklift. After more than 4 hours of soaking, the soaked broken slag iron is transferred to the slagging area by an excavator, and the soaked broken slag iron is broken with a slag breaker. , Take out the scum on the surface of the broken slag iron, so that this part of the broken slag iron can be further purified, and the high-purity slag iron can be returned to steelmaking. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com