Treatment method of highly saturated non-uniform dredging fill soil foundation

A treatment method and technology of soil foundation, applied in soil protection, infrastructure engineering, construction and other directions, can solve problems such as inability to improve the unevenness of foundation soil, and achieve the effect of satisfying strength, improving unevenness and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

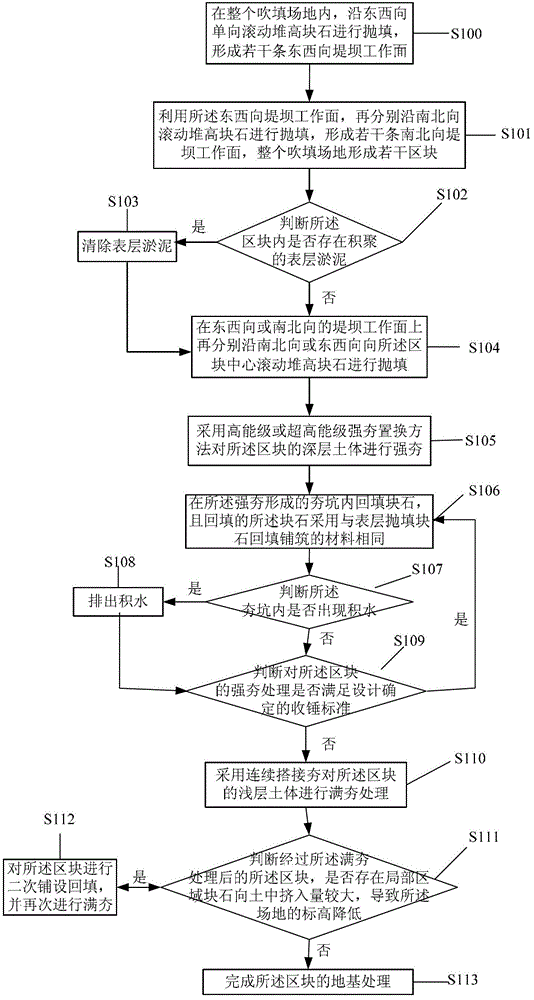

[0037] Such as figure 1 Shown, the highly saturated heterogeneous dredging fill foundation treatment method of the present invention comprises the following specific steps:

[0038] In step 100, within the entire dredging reclamation site, rolling piles of high rocks along the east-west direction are thrown and filled to form several east-west dyke working faces.

[0039] In step 101, use the east-west dike working face, and then pile up rocks along the north-south direction respectively for throwing and filling, forming several north-south dike working faces, and the entire dredging and filling site forms several blocks.

[0040] Step 102, judging whether there is accumulated surface silt in the block; if yes, proceed to step 103; if not, proceed to step 104.

[0041] Step 103, removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com