A Rotary Drill Rig with Controllable Compressed Gas Injection Rate

A technology of injection rate and compressed gas, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as affecting the drilling quality, inaccurate drilling position or angle, and offset of the top of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

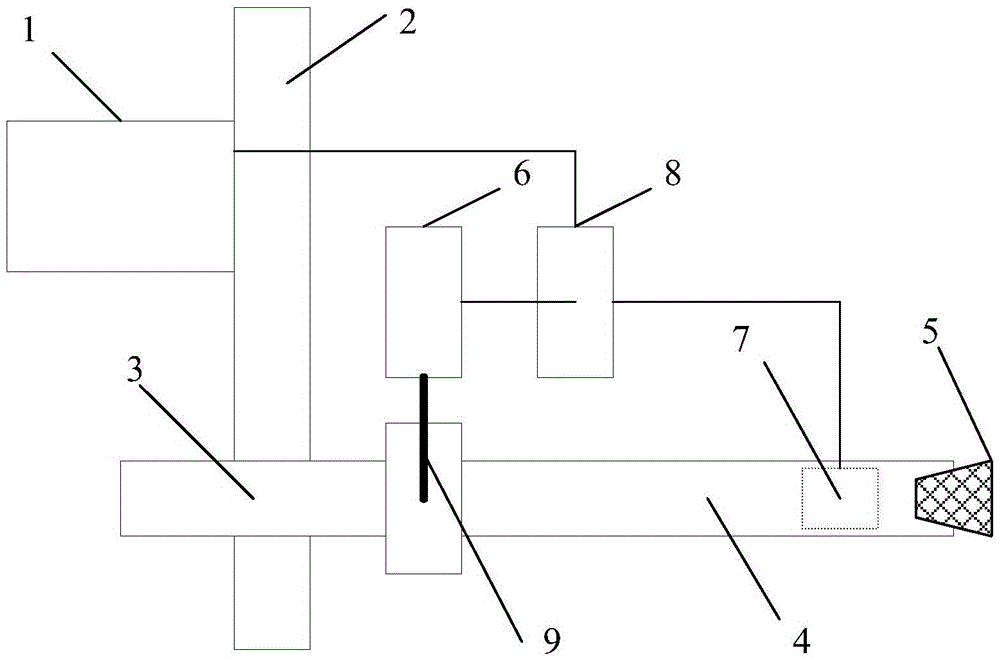

[0018] Embodiments of the present invention provide a roller cone drill with controllable compressed gas injection rate, such as figure 1 As shown, it includes a motor 1, a reducer 2, a hollow drill rod 4 and a drill bit 5, a compressed air tank 6, a detection unit 7 and a numerical control unit 8. Among them, the reducer 2 plays the role of matching speed and transmitting torque between the motor 1 and the hollow drill pipe 4, and can be divided into a general reducer and a special reducer according to the application. The input end of the reducer 2 is connected with the output shaft of the motor 1 , the hollow output shaft 3 of the reducer 2 communicates with one end of the hollow drill rod 4; the other end of the hollow drill rod 4 is equipped with a drill bit 5.

[0019] Described compressed air tank 6, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com