Novel container valve for fire trace tube fire-extinguishing device

A technology of fire extinguishing device and fire detection tube, which is applied in valve device, lift valve, fire rescue and other directions, can solve the problems of wrong opening of container valve, insufficient fire extinguishing time and lack of rationality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

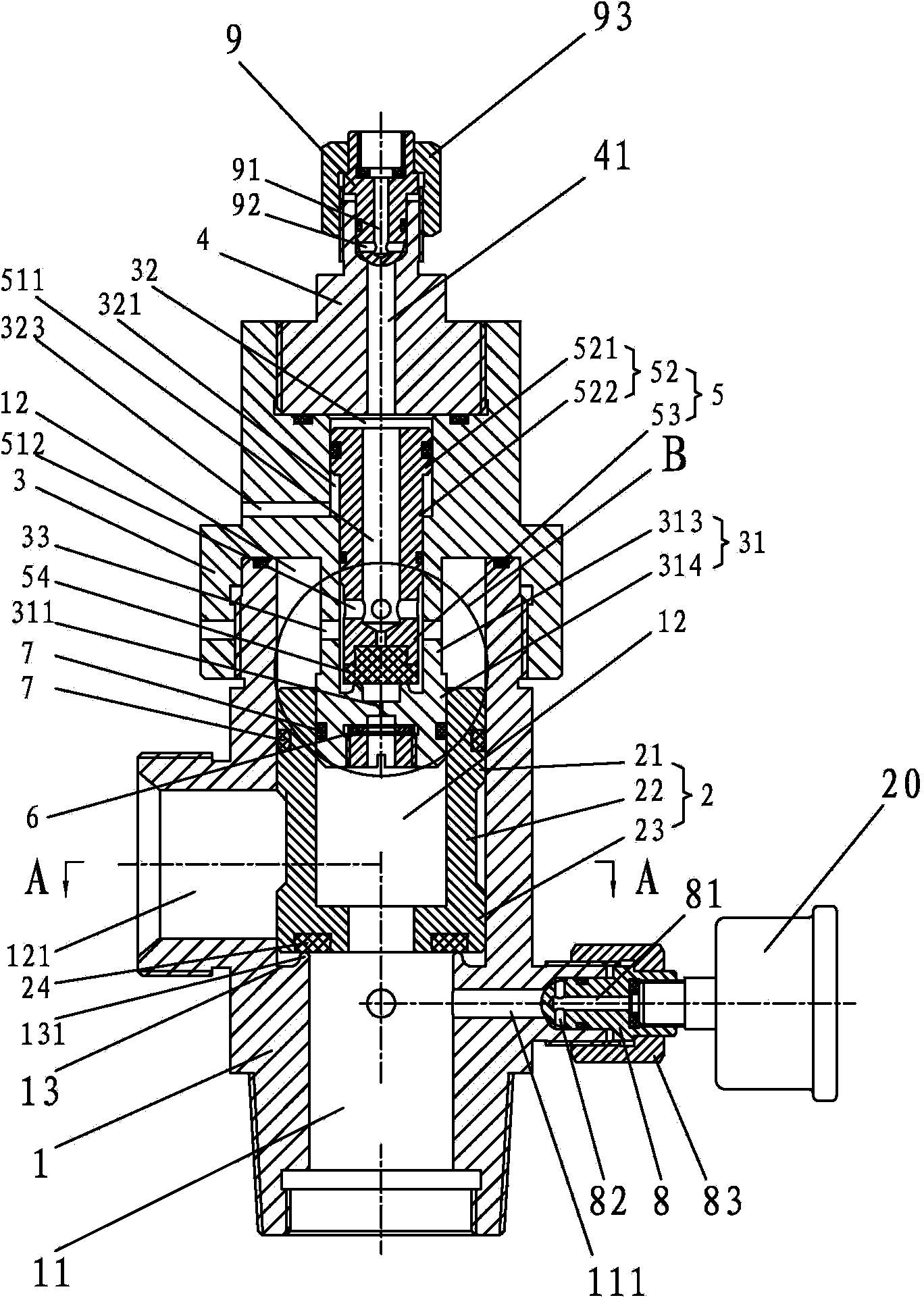

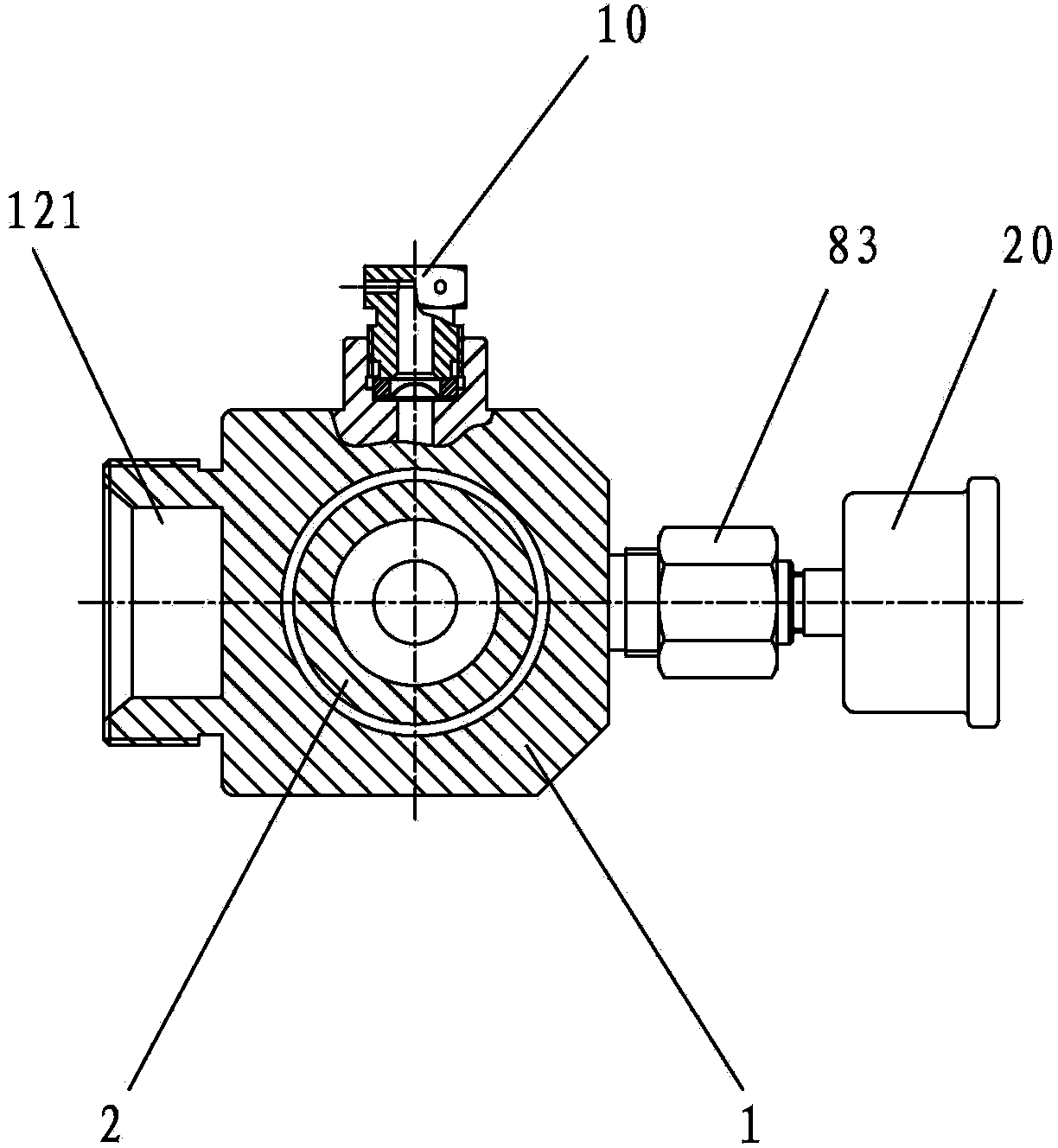

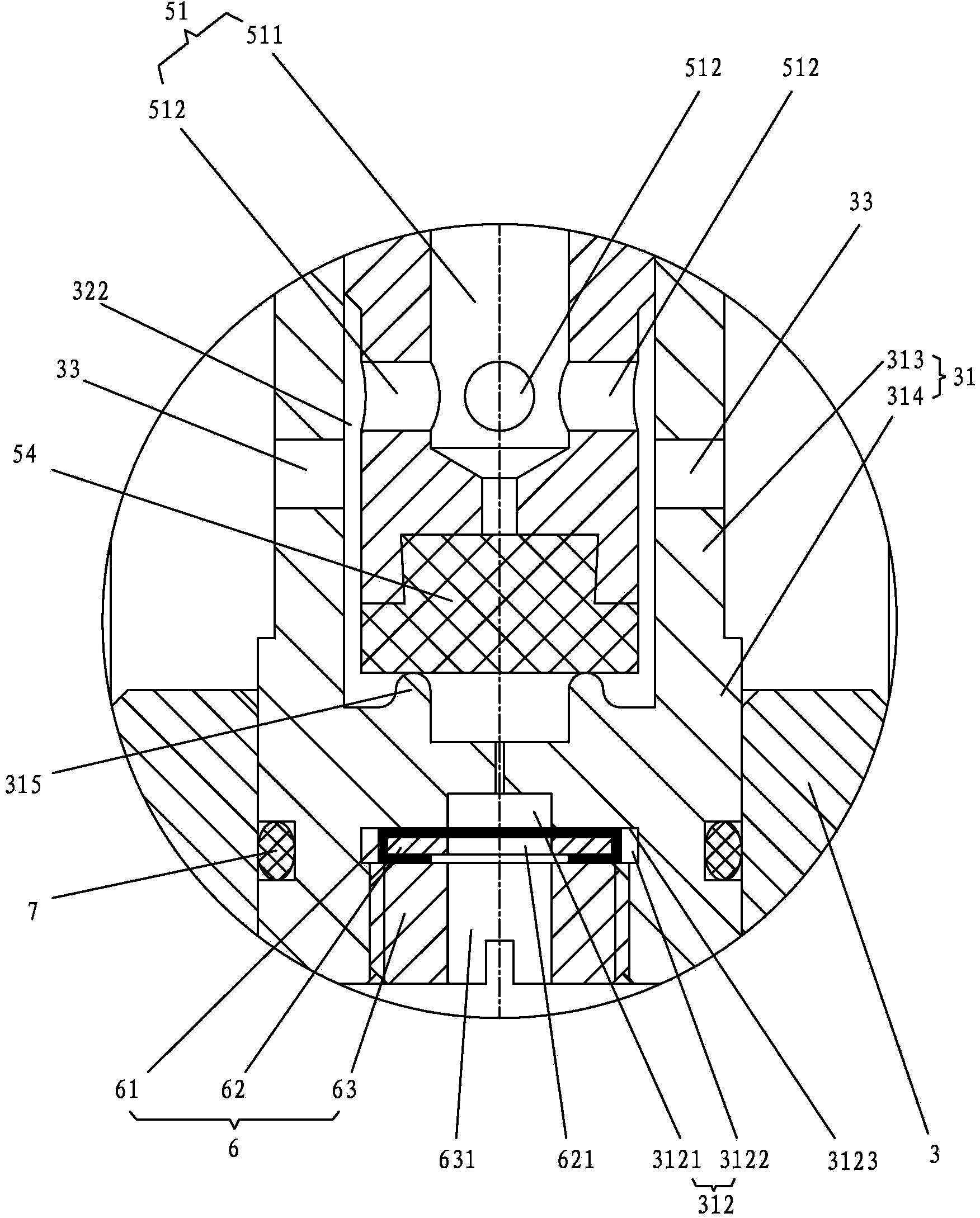

[0054] The novel container valve of a kind of fire detection tube fire extinguishing device of the present invention, as Figure 1-4 As shown, it includes a valve body 1, a valve disc 2, a valve cover 3 and a gland 4 communicating with a fire detection tube (not shown in the figure).

[0055] The valve body 1 has a lower chamber 11 that communicates with the fire extinguishing agent container (not shown in the figure) and has a lower inflation port 111, and an upper chamber 12 with a fire extinguishing agent nozzle 121; the valve cover 3 is connected to the valve in a sealed and firm manner. The upper end of the body 1; the gland 4 is connected to the upper end of the valve cover 3 in a sealed and firm manner; the valve cover 3 extends coaxially downwards with an extension 31 in the upper chamber 12, and the valve flap 2 is slidable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com