Kitchen ventilator, spiral case and volute tongue thereof

The technology of a range hood and a volute tongue is applied in the field of a volute casing and its volute tongue structure, which can solve the problems of whistling, noise, and difficulty to achieve, and achieve the effects of smooth airflow, noise reduction and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

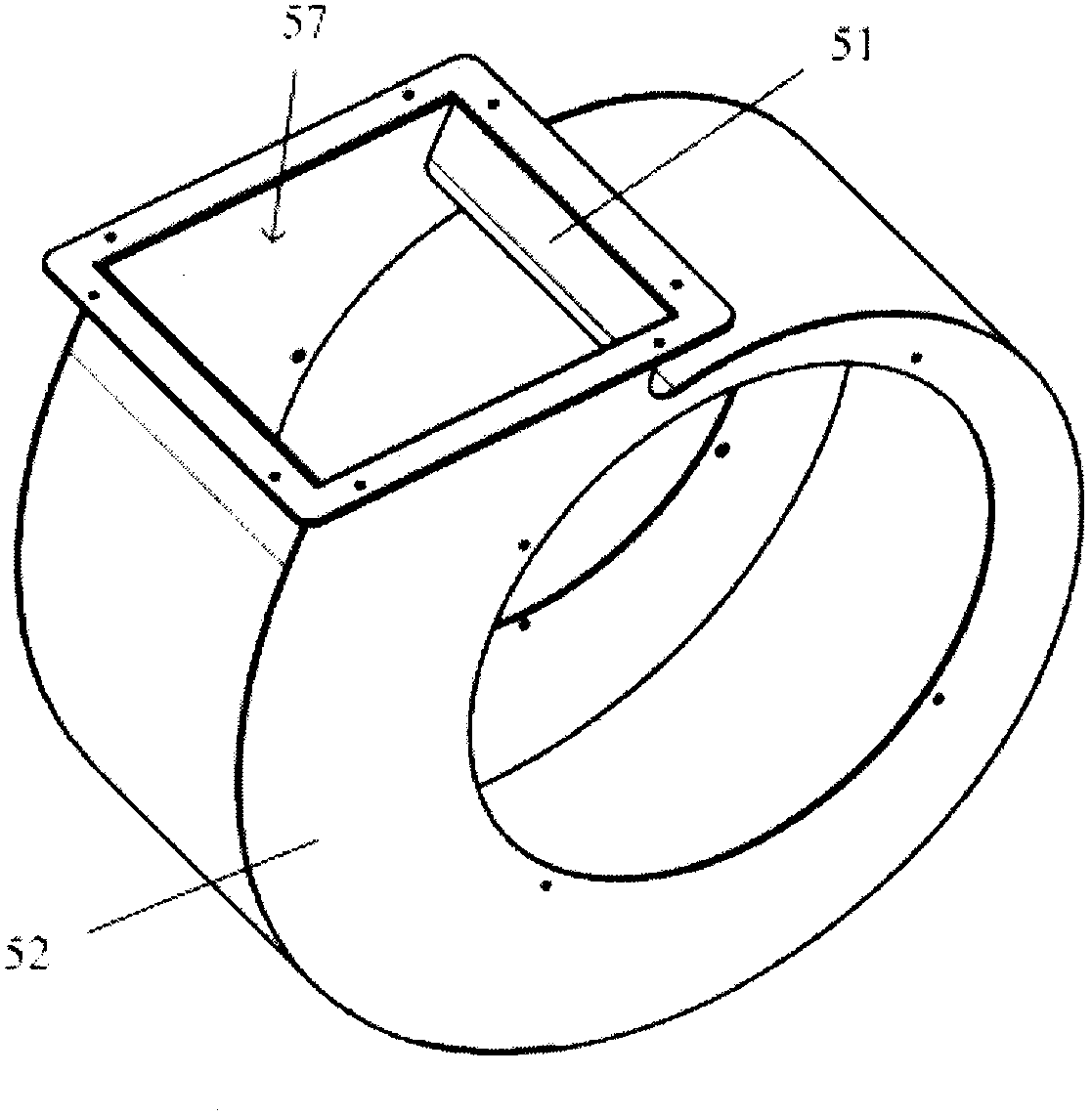

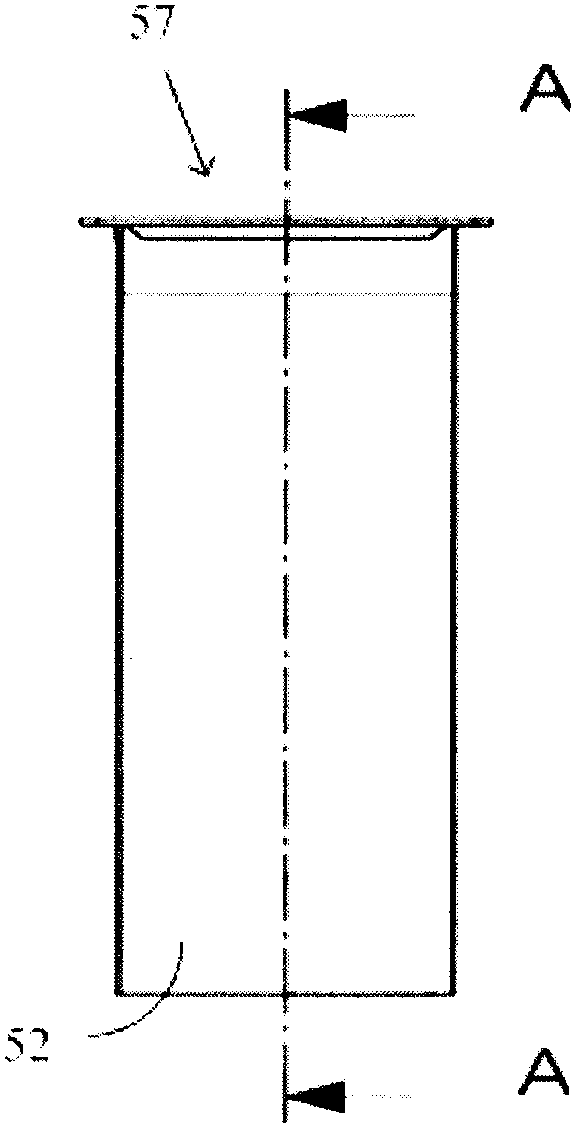

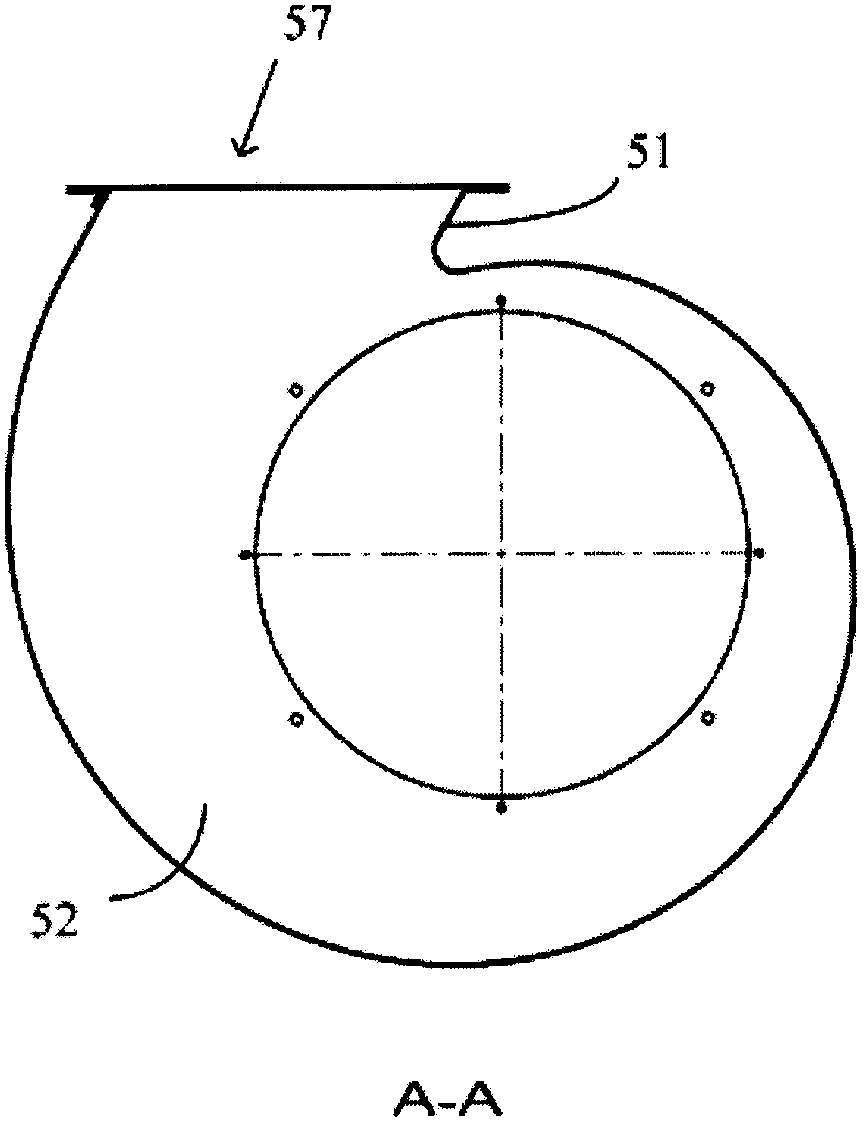

[0041] The following combination Figure 4 to Figure 8 The situation of the volute tongue and the volute case in this embodiment will be described in detail. in, Figure 4 to Figure 5 A schematic diagram of the volute provided in this embodiment, Figure 6 to Figure 7 shown in Figure 4 to Figure 5 The volute tongue in the volute shown in, Figure 8 A schematic diagram of the volute for installing the volute tongue provided in this embodiment.

[0042] The volute 2 provided in this embodiment is as Figure 4 As shown above, it is a helical, snail-shaped shell with a body 206 and an air outlet 207 that protrudes along the tangential direction of the circular part of the body. There is a volute tongue 1 where the main body 206 and the air outlet 207 meet.

[0043] In this embodiment, the volute tongue 1 is a separately processed structure, and then installed on the body 206, as Figure 5 shown. In this way, the volute 2 does not need to form a recessed volute tongue stru...

Embodiment 2

[0052] In this embodiment, similar to the first embodiment, the volute tongue has the same inner concave surface, and is additionally installed on the volute case. The difference is that the volute tongue does not have an upper connection surface or a lower connection surface. The volute has a hollow part at a corresponding position, and a flange part is provided on the edge of the hollow part, so as to be suitable for installing the volute tongue. The installation method may also be one of pasting, welding, screw fixing, rivet fixing and the like. The features in other aspects are similar to those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] In this embodiment, the volute tongue is the same as the volute tongue in the first embodiment.

[0055] The volute has hollow parts at corresponding positions adapted to install the volute tongue. The volute tongue can also be installed in the volute by sticking, welding, etc., or an external connection part (not shown) is provided on the edge of the upper connecting surface and the lower connecting surface away from the inner concave surface. , to fit on the volute. Correspondingly, the external connection part may be a convex line adapted to the shape of the inner surface of the volute, so as to be suitable for sticking, welding, screw fixing, rivet fixing and the like. Alternatively, the outer connection part is set as a clamping foot, so as to be suitable for being installed on the volute in a clamping manner, and correspondingly, a bayonet is provided at the edge of the hollow part of the volute, so as to be suitable for installing the volute tongue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com