Smoke amount measuring and control device and smoke amount measuring and control method of semi-closed ferroalloy submerged arc furnace

A ferroalloy, flue gas volume technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as malfunction of the electric control system of the furnace door and large difference in flue gas volume, achieve high sensitivity, avoid misoperation, Avoid the effect of false movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

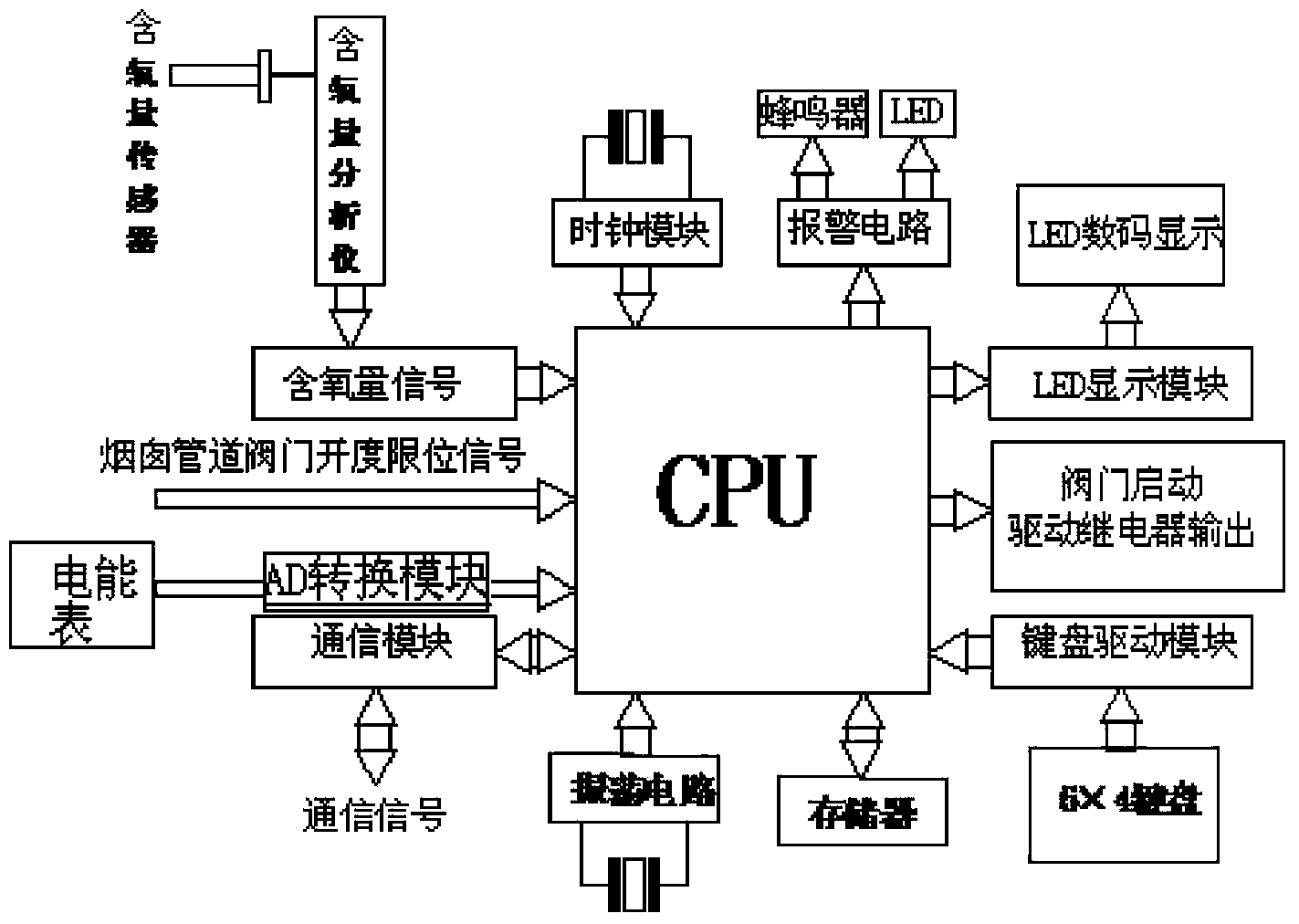

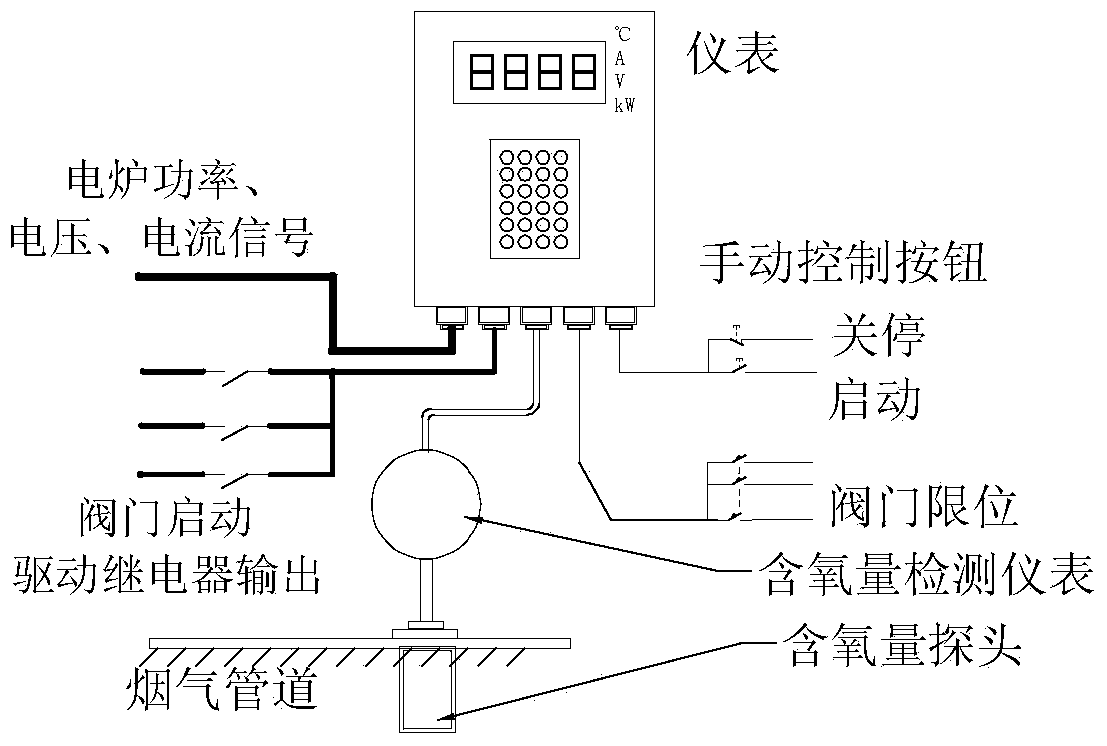

Method used

Image

Examples

Embodiment 1

[0044] The invention is applied to flue gas volume measurement and control for flue gas waste heat power generation. A 20MVA manganese-silicon ferrosilicon alloy submerged arc furnace is equipped with a flue gas waste heat boiler. The flue gas in the furnace is exchanged through the waste heat boiler under the action of the frequency conversion induced draft fan, and then sent to the bag dust removal device to purify the flue gas. The flue gas purified by the bag Exhaust from the exhaust stack. The flue gas waste heat power generation pipeline and waste heat boiler system require the flue gas volume to be controlled at 30000Nm 3 / h~530 million N m 3 / h range. The above objectives can be achieved through the following implementation methods.

[0045] Install the probe of the sensor at a height of 2-3 meters in the purified flue gas exhaust pipe after the flue gas dedusting of the submerged arc furnace, and extend the probe into any position in the exhaust cross-section to sa...

Embodiment 2

[0047] The invention is applied to the dedusting and purification treatment of the flue gas of the submerged arc furnace. A company's 2×25MW submerged arc furnace flue gas dust collector system, the exhaust capacity and pressure head can meet the maximum load requirements. The submerged arc furnace door of the dust removal system is equipped with an electric switch device. The company originally controlled the amount of air inhaled by the furnace by manually controlling the size of the furnace hood door. The dust collector is designed to treat the flue gas volume of the filter bag, that is, the rated flue gas volume is 250000Nm 3 / h, minimum not less than 150000Nm 3 / h, an adjustable mechanical cooler is set in front of the dust collector, and the cooling capacity can meet the requirements of the worst furnace conditions. The following implementation methods can be used to ensure that the flue gas volume treated by the filter bag of the dust collector is within the rated flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com