Pure I type dynamic fracture test piece for hard composite material

A composite material, I-type technology, applied in the direction of analysis materials, preparation of test samples, instruments, etc., can solve the problem of not considering the influence of accuracy and authenticity, so as to facilitate the propagation of stress waves, avoid asymmetric loading, and reduce stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention is a pure I-type dynamic fracture test piece of hard composite material, the overall shape is a disk-shaped structure, the upper and lower surfaces are parallel to each other, the thickness of the disk is 0.2 times the diameter, and two platforms are symmetrically arranged on the circumference of the disk. The two platforms are parallel and have the same size. A penetrating straight groove crack is set in the diameter direction between the two platforms on the disc. The length of the penetrating straight groove crack is 0.6 times the diameter of the disc. The penetrating straight groove crack is about the The position of the center of the circle is symmetrical; the platform is perpendicular to the through-straight-groove crack, and the center angle corresponding to the length of the through-straight-groove crack is 15°.

Embodiment 2

[0024] The present invention is a pure I-type dynamic fracture test piece of hard composite material, the overall shape is a disk-shaped structure, the upper and lower surfaces are parallel to each other, the thickness of the disk is 0.3 times the diameter, and two platforms are symmetrically arranged on the circumference of the disk. The two platforms are parallel and have the same size. A penetrating straight groove crack is set in the diameter direction between the two platforms on the disc. The length of the penetrating straight groove crack is 0.7 times the diameter of the disc. The penetrating straight groove crack is about the The position of the center of the circle is symmetrical; the platform is perpendicular to the through-straight-groove crack, and the center angle corresponding to the length of the through-straight-groove crack is 30°.

Embodiment 3

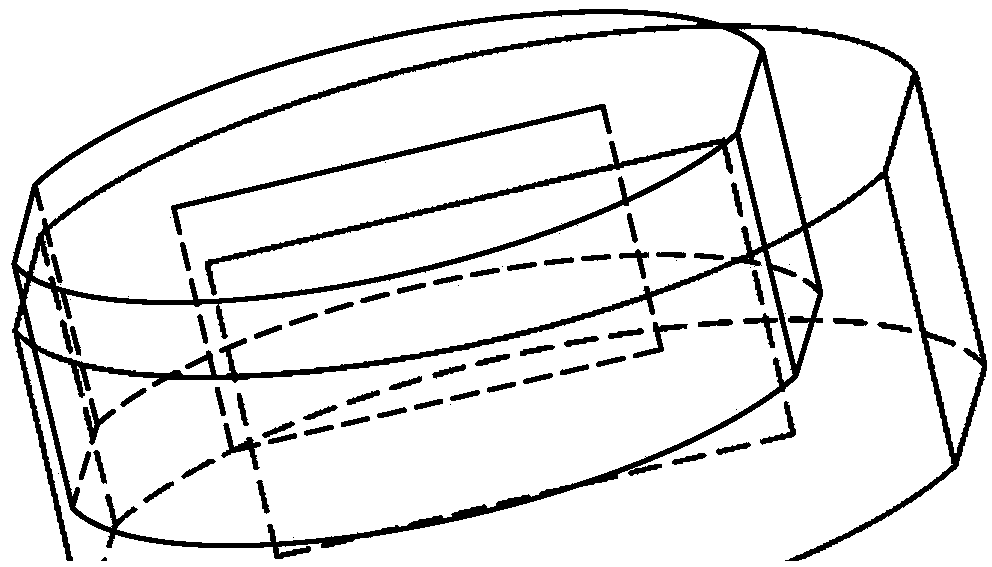

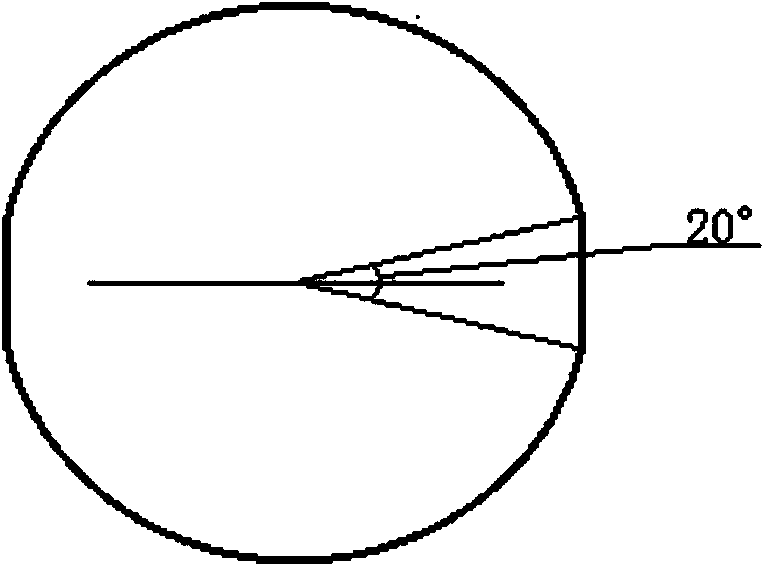

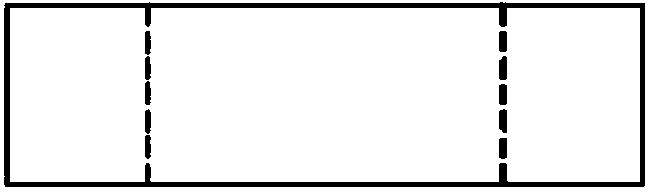

[0026] Such as figure 1 , 2 , as shown in 3:

[0027] The present invention is a pure I-type dynamic fracture test piece of hard composite material, the overall shape is a disk-shaped structure, the upper and lower surfaces are parallel to each other, the thickness of the disk is 0.25 times the diameter, and two platforms are symmetrically arranged on the circumference of the disk. The two platforms are parallel and have the same size. A through-straight-groove crack is set in the diameter direction between the two platforms on the disc. The length of the through-straight-groove crack is 0.5 times the diameter of the disc. The position of the center of the circle is symmetrical; the platform is perpendicular to the through-straight groove crack, and the center angle corresponding to the length of the through-straight groove crack is 20°.

[0028] combined with figure 1 , the structural feature is disc-shaped, and the center angle corresponding to the platform is 20°, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com