Groove step surface self-returning type electromagnet

A stepped surface and electromagnet technology, applied in the field of electromagnets, can solve the problems of the natural frequency of the electromagnet affecting the return time of the armature, the difficulty of maintenance, and the complicated internal structure, etc., and achieve simple structure, low manufacturing cost, and good restoring force characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

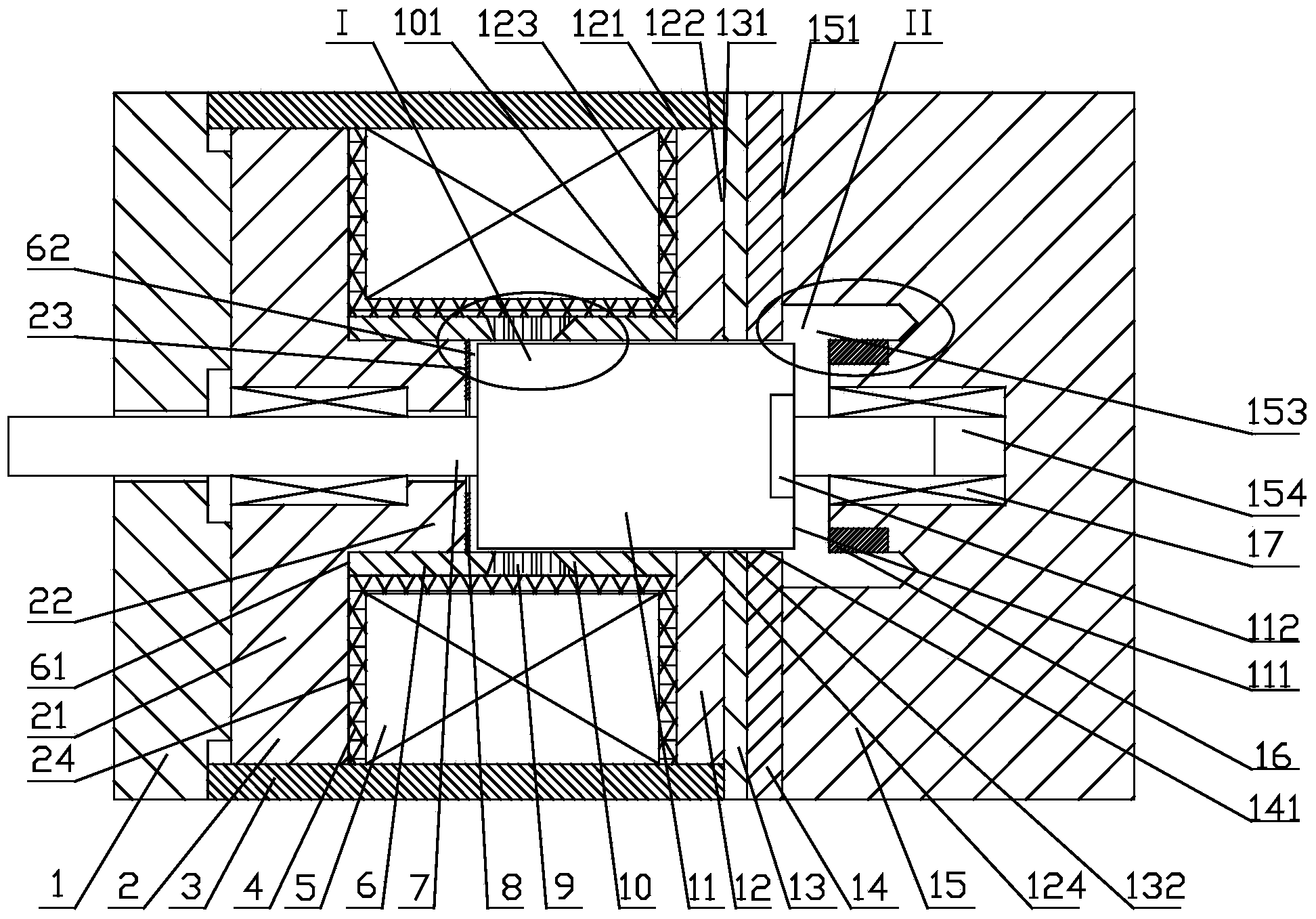

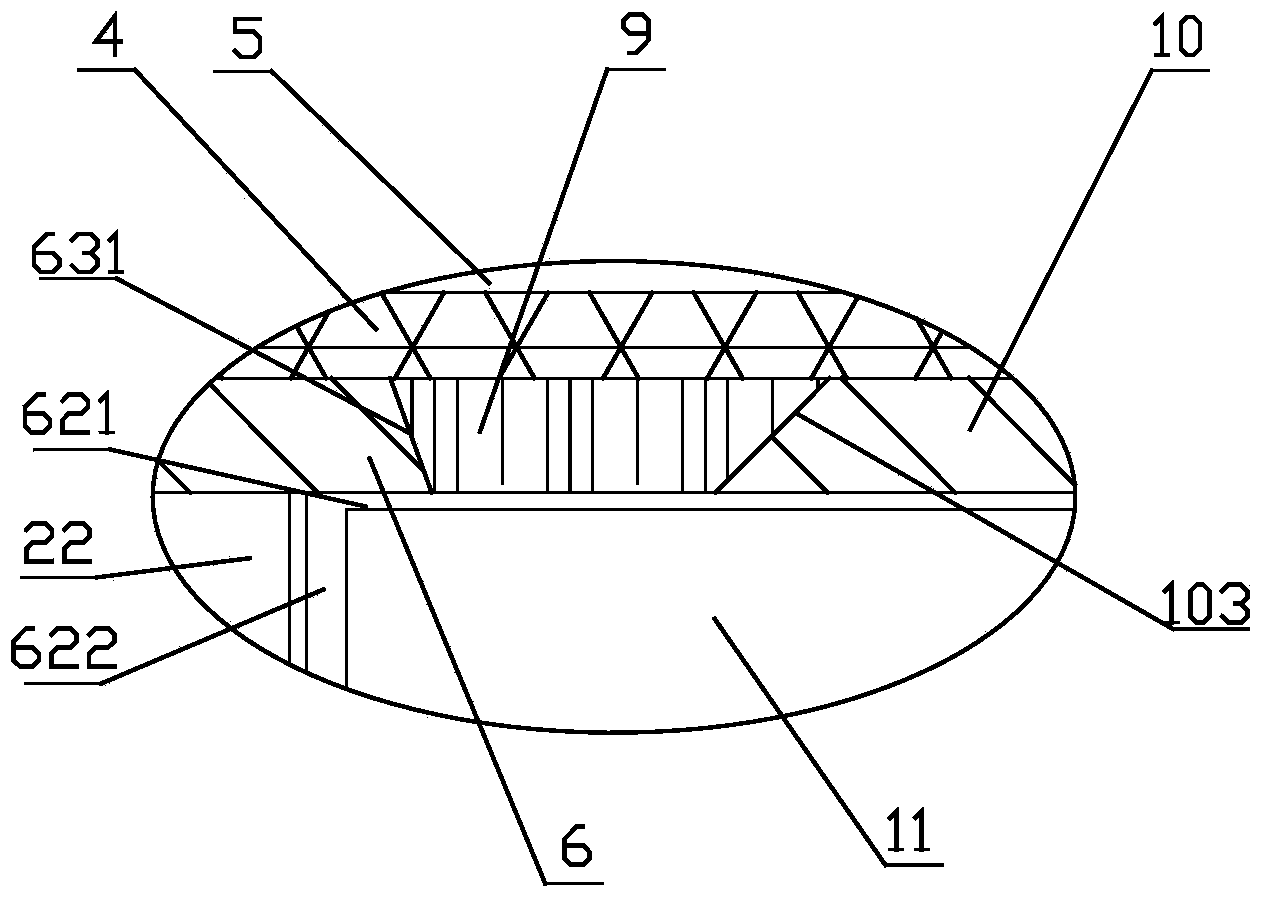

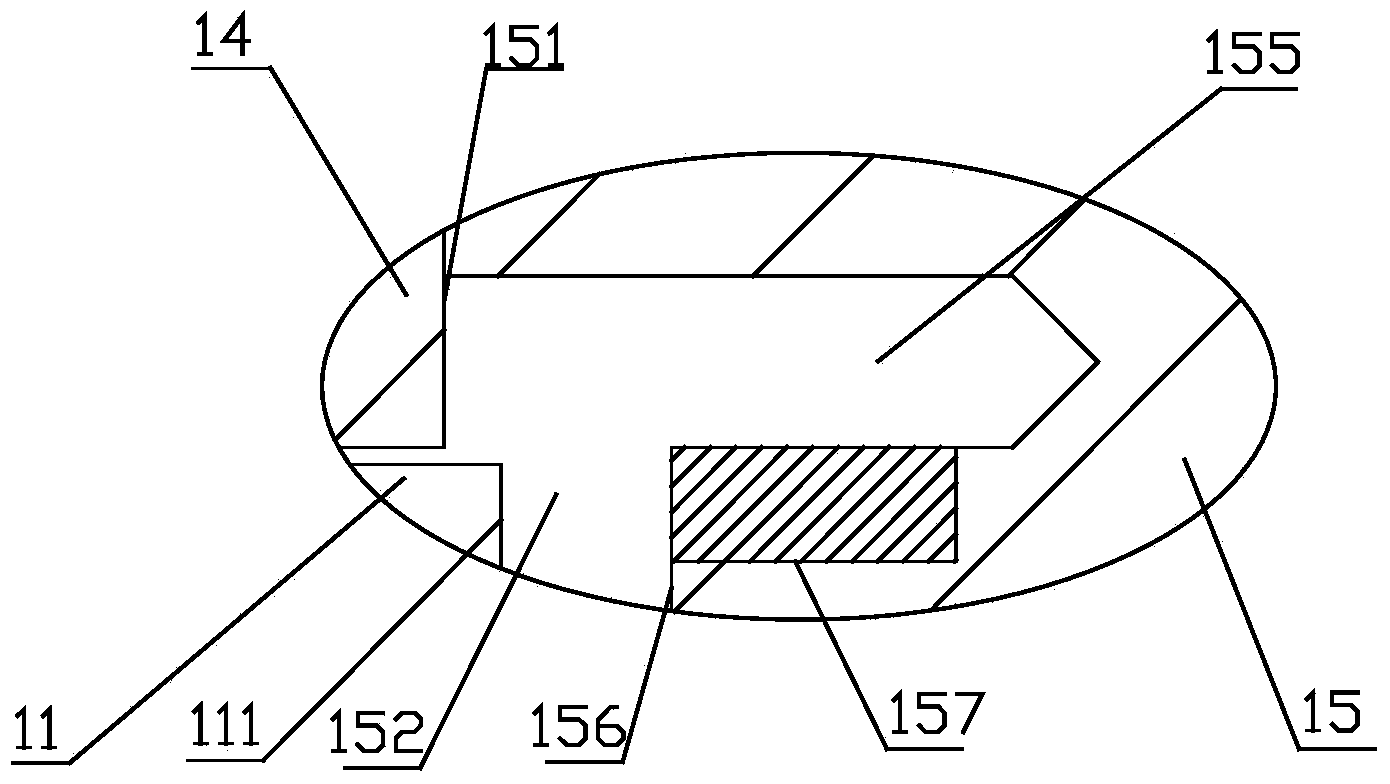

[0028] Embodiment 1, figure 1 A permanent magnet return type high-speed switching electromagnet is given, including a front cover 1, a stopper 2, a casing 3, a coil frame 4, a control coil 5, a leading magnetic sleeve 6, a push rod 7, a limit piece 8, a magnetic isolation Cover 9, rear magnetic guide cover 10, armature 11, flange 12, magnetic isolation sheet 13, magnetic guide sheet 14, rear end cover 15, annular permanent magnet 16 and bearing 17. The above-mentioned block 2, shell 3, front magnetic sleeve 6, rear magnetic sleeve 10, armature 11, flange 12, magnetic sheet 14 and rear end cover 15 are all magnetic guides made of magnetic materials. The magnetic cover 9 is made of non-magnetic material.

[0029] The shell 3 is provided with a cylindrical shell cavity (the left end and the right end of the shell cavity are both connected), the left end of the shell 3 is provided with a front cover 1, the right end of the shell 3 is provided with a magnetic isolation sheet 13, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com