Light emitting diode structure and method for manufacturing thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of long manufacturing process time, poor productivity, high labor and manufacturing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

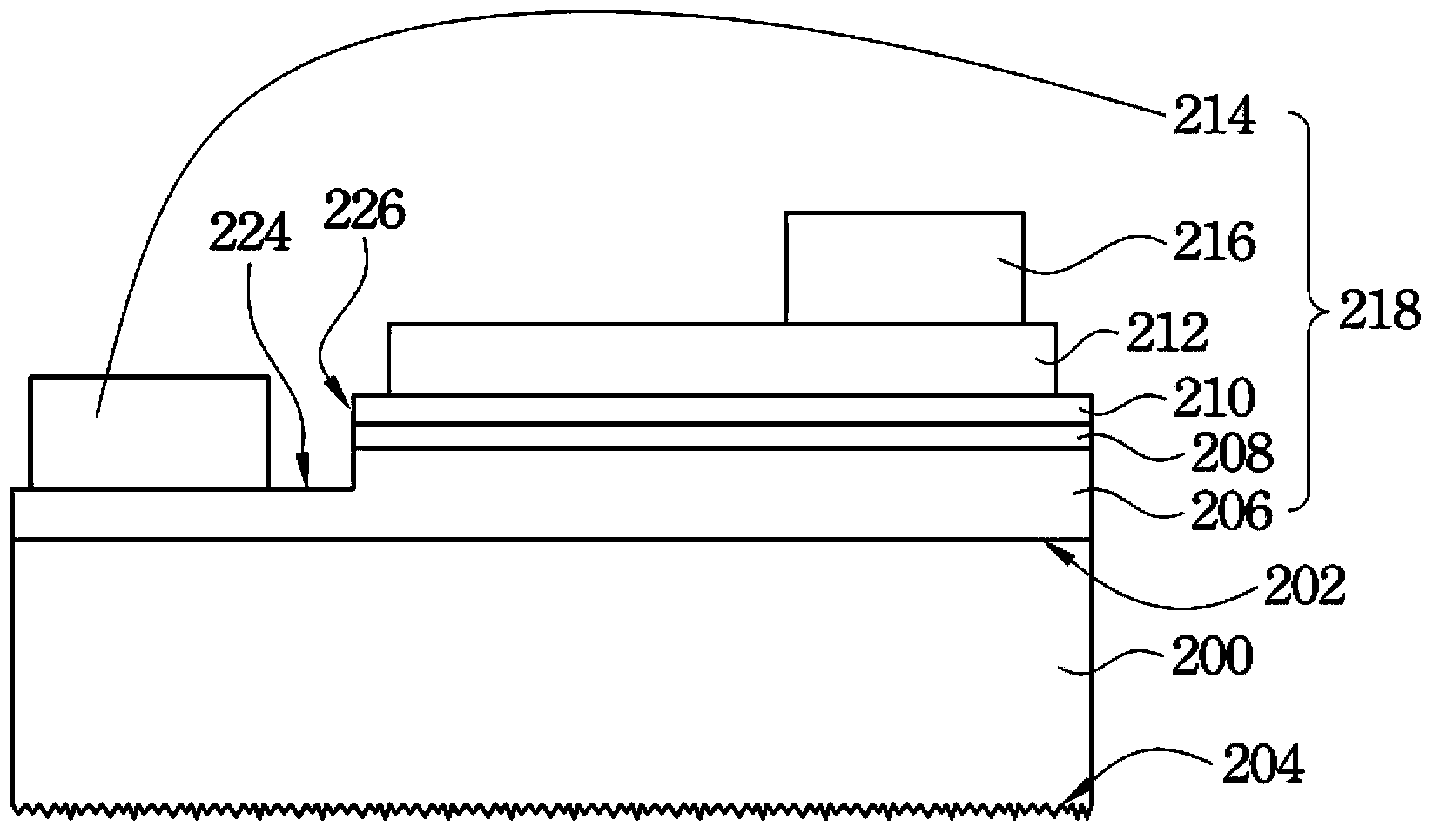

[0045] Please refer to Figure 3A to Figure 3C , which is a cross-sectional view illustrating a manufacturing process of a light emitting diode structure according to an embodiment of the present invention. In this embodiment, the light emitting diode structure 222 mainly includes a transparent substrate 200, a light emitting structure 218 and a metal reflector 220, such as Figure 3C shown. The LED structure 222 only includes a single metal reflector 220, but does not have the distributed Bragg reflectors of conventional LED structures.

[0046] Such as Figure 3A As shown, when fabricating the LED structure 222, the transparent substrate 200 is provided first. The transparent substrate 200 includes surfaces 202 and 204 , wherein the surfaces 202 and 204 are respectively located on opposite sides of the transparent substrate 200 . The transparent substrate 200 can be, for example, a sapphire substrate.

[0047]Next, a light emitting structure 218 is formed on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com