Three-phase asynchronous motor skewed-slot rotor structure

A skewed rotor, three-phase asynchronous technology, applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of poor technical solutions for supporting parts, noise environmental pollution, electromagnetic noise, etc. Effects of noise pollution, reduction of electromagnetic noise, and improvement of starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

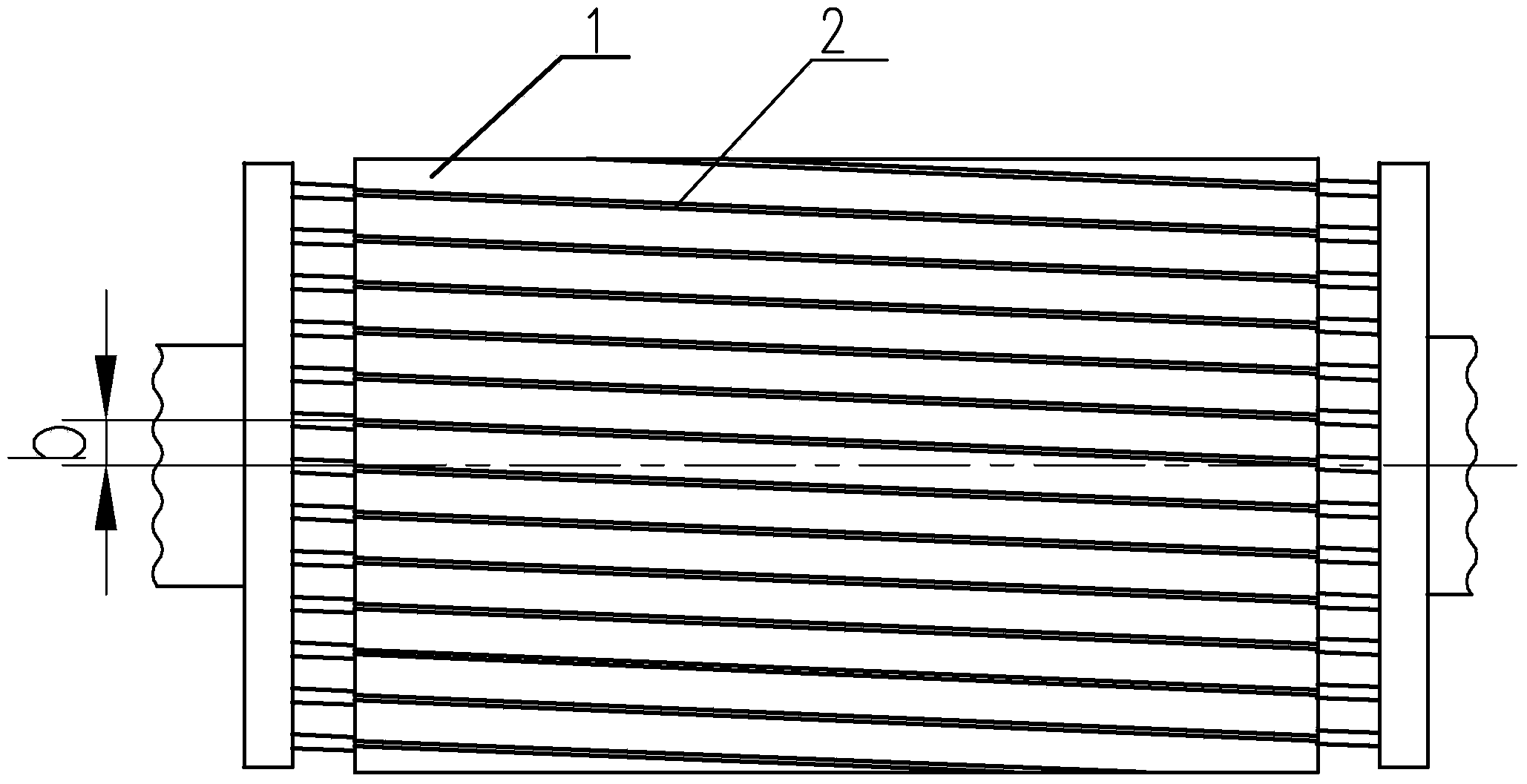

[0010] figure 1 As shown, the rotor body 1 is included, and the rotor body 1 is provided with a number of rotor chute 2, and the value b of the rotor chute is 26.7 mm; b is a stator tooth pitch. The outer diameter of the rotor body 1 is 356.8 mm; the length of the rotor core is 560 mm.

[0011] The present invention only needs to change the angle of the skewed groove of the rotor, and does not change the original assembly mode of the motor. When the rotor straight slot is changed to an inclined slot, the rest remains unchanged, the electromagnetic noise is significantly reduced, and no noise environmental pollution is generated; and the mechanical loss of the motor and the stray loss of the motor are also reduced. It has been widely used in high-voltage high-efficiency center high On the rotor core of Y2-HV315X-4-355KW 6KV motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com