Assembled tobacco seedling culturing system

A technology of tobacco and seedling tube, which is applied in the application, cultivation, agriculture and other directions, can solve the problems of difficulty in cultivating strong seedlings for tobacco seedlings, restricting the development of seedling raising work, and high labor cost for seedling raising, so as to reduce the seedling raising process and shorten the time for tobacco seedlings to return to seedlings. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

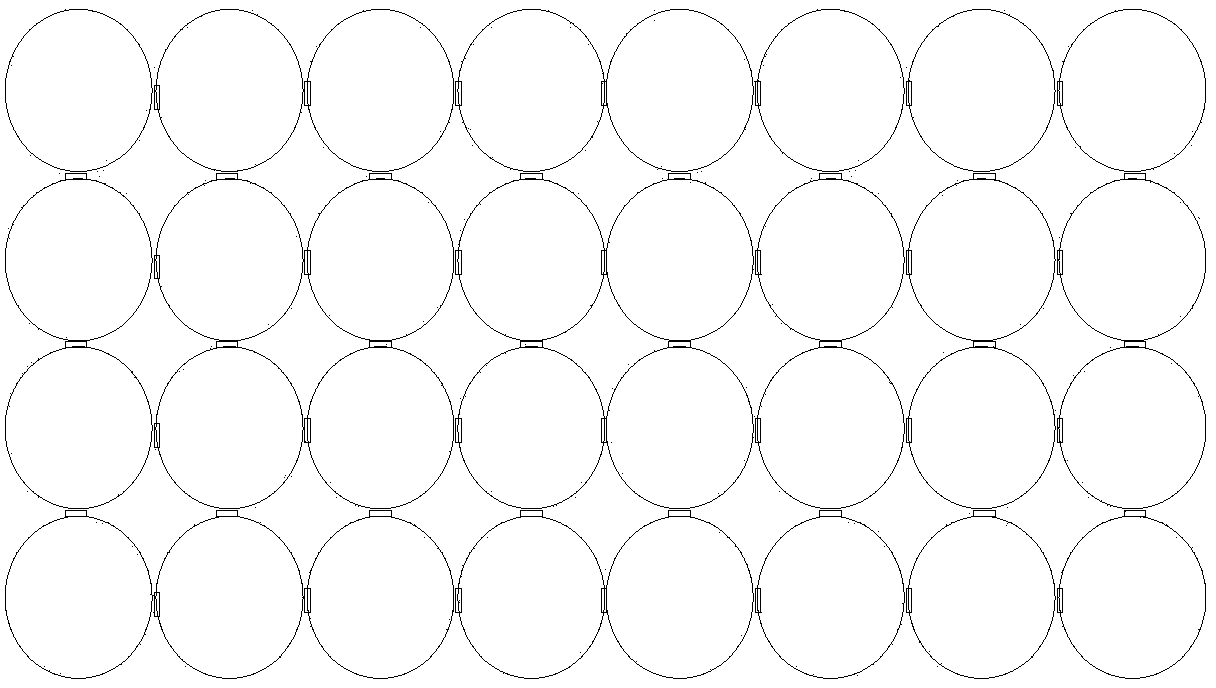

[0017] as attached figure 1 The tobacco seedling raising device of the present invention, the cross section of the seedling raising tube is circular, and is made up of a plurality of cylindrical seedling raising tubes, assemblies 4 and seedling raising substrate 5, wherein, each seedling raising tube is composed of a tube edge 1, a tube cover 2 and a tube bottom 3 is a closed cylinder, and the seedling raising tube is filled with a seedling raising matrix 5; each seedling raising tube is connected through the assembly 4 to form an interconnected seedling raising tube group, which serves as a seedling raising operation unit.

[0018] The height of the cylindrical sports seedling tube is 10cm, and the diameter is 8cm. Its tube edge, tube cover and tube bottom are all made of non-woven fabric net with 2-3mm aperture.

[0019] Seedling raising substrate consists of 60% loam soil, 40% farm manure, 0.3% tobacco special fertilizer (N:P 2 o 5 : K 2 O ratio is 11:12:24, NO 3 - ≥40...

Embodiment 2

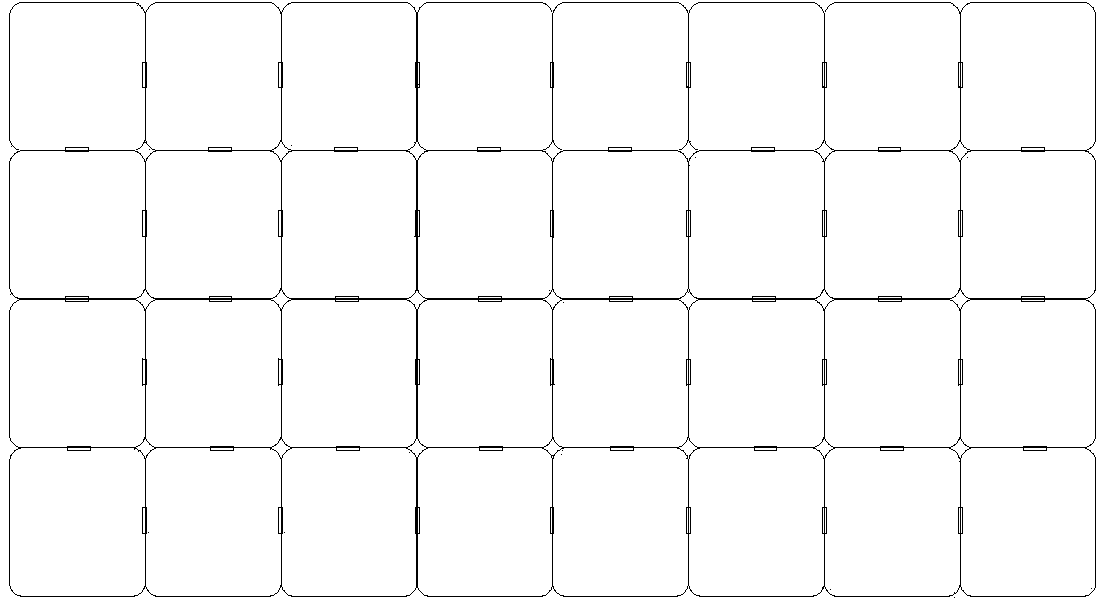

[0022] as attached figure 2 The assembly type tobacco seedling raising device of the present invention, the cross section of seedling raising tube is the square of 5cm * 5cm, is made up of a plurality of square column seedling tubes, assemblies 4 and seedling raising substrate 5, and the height of square column seedling tube is 10cm, and its tube The side, the cylinder cover and the cylinder bottom are all made of non-woven fabric nets with an aperture of 2-3mm; the assembly 4 is made of suture thread; the rest are the same as in embodiment 1.

Embodiment 3

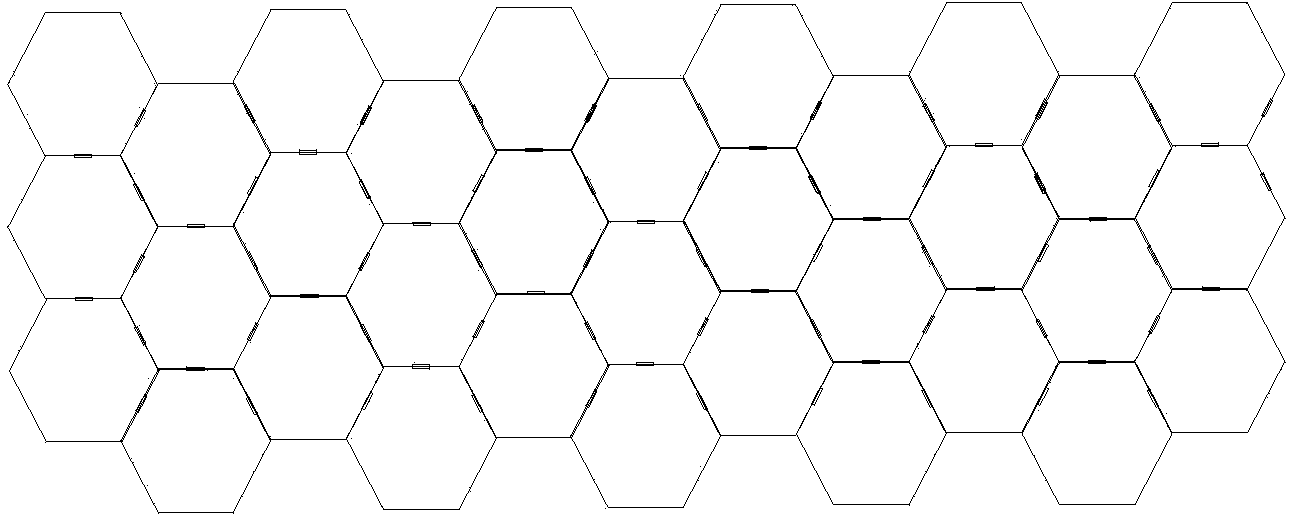

[0024] as attached image 3 The assembled type tobacco seedling raising device of the present invention, the cross section of seedling raising tube is the regular hexagon of side length 2cm, is made up of a plurality of seedling raising tubes, assembly 4 and seedling raising substrate 5, and the height of seedling raising tube is 10cm, and its tube edge, tube cover Both the bottom and the bottom of the cylinder are made of non-woven fabric net with a pore size of 2-3mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com