Tube array hole jet flow jet mixer

A jet mixer, tube-and-tube technology, applied in fluid mixers, mixers, chemical/physical/physicochemical fixed reactors, etc., can solve the problems of poor operational stability of mixers and uneven fluid distribution, and achieve Good mixing effect, efficient mixing process, and the effect of inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

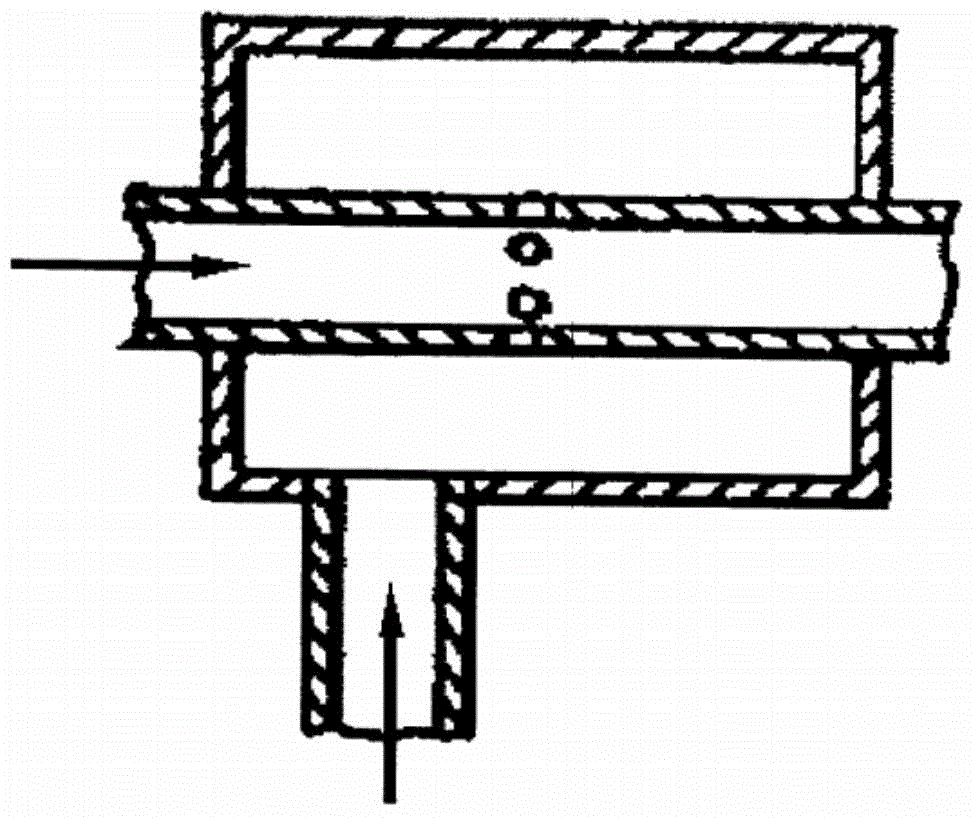

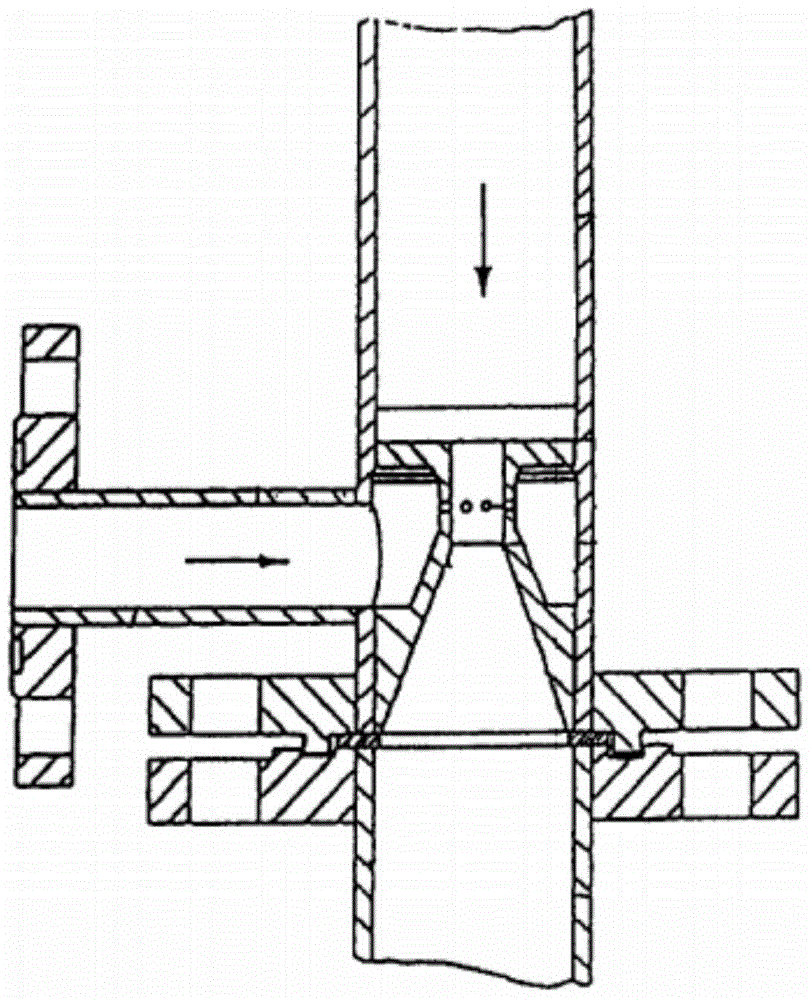

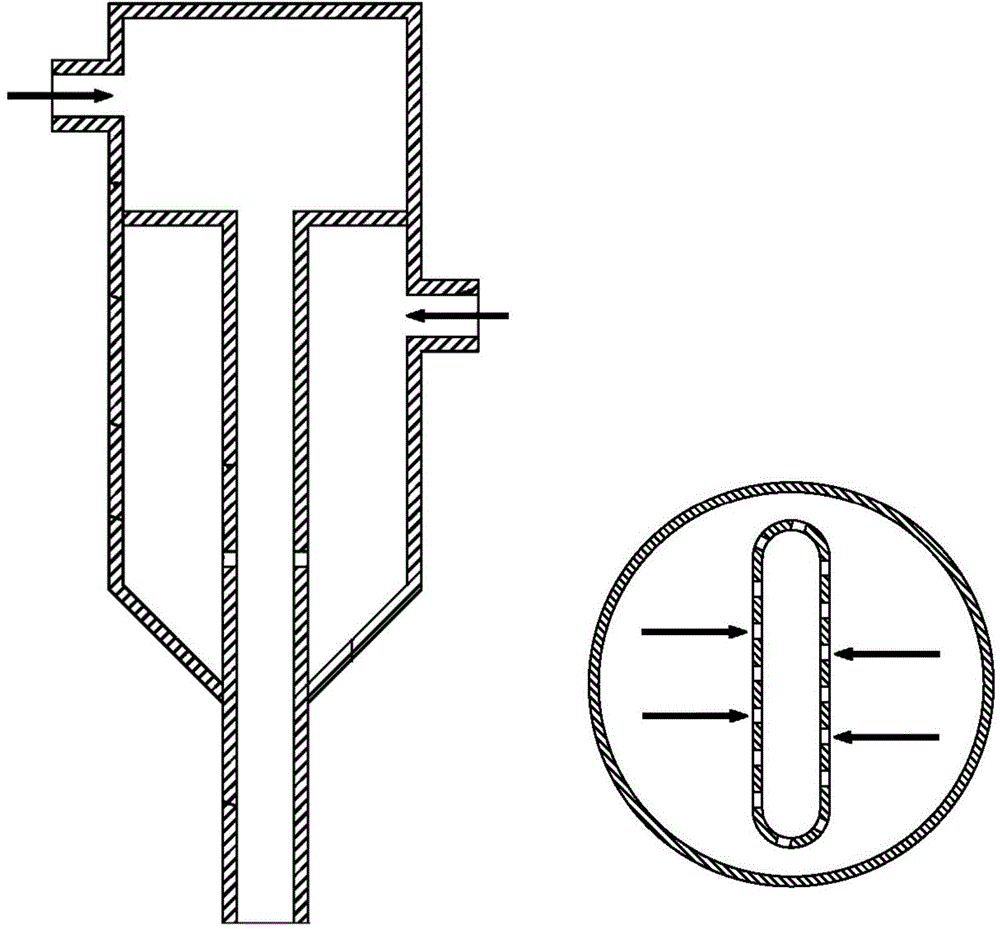

[0038] The tubular orifice jet mixer has the structure as above, and its specifications are: the inner diameter of the shell 1 is 200 mm; the inner diameter of the inner sleeve 3 is 20 mm, the total length of the inner sleeve 3 is 500 mm, and the length of the mixing zone 7 is is 20mm; the arrangement of the inner casing 3 in the housing 1 is as follows Figure 6 In the equilateral triangle arrangement shown, the number of the inner casing 3 is 19, the diameter of the jet hole 4 on the inner casing 3 is 4mm, and the number of the jet holes 4 on each inner casing 3 is 4, The small jet holes 4 are evenly distributed on the same cross section of the inner casing 3 .

[0039] The aqueous solution containing tracer Rhodamine B is continuously injected into the annulus of the mixer from the first feed port 8, and the concentration of Rhodamine B is 100mg / m 3 , the gauge pressure at the first feed port 8 is 3.5bar, and the flow rate of fluid B at the first feed port 8 is 20m 3 / hr....

Embodiment 2

[0042] Adopt the shell-and-tube hole jet mixer of the same structure and size as Example 1, if only the flow at the first feed port 8 is changed to 30m 3 / hr, and the rest of the operating conditions remain unchanged.

[0043] The mixing process of the mixer is measured by laser-induced fluorescence technology. At this time, the distance between the transverse section of the two fluids when the mixing degree reaches 95% and the transverse section where the center of the jet hole is located is 26mm. The time corresponding to the mixing process The scale is about 11.2ms.

Embodiment 3

[0045] Using the same structure and size of the tube-type hole jet mixer as in Example 1, only the number of jet holes 4 on the inner sleeve is changed to 6, and the operating conditions are also consistent with Example 1.

[0046] The mixing process of the mixer is measured by laser-induced fluorescence technology. At this time, the distance between the transverse section of the two fluids when the mixing degree reaches 95% and the transverse section where the center of the jet hole is located is 24mm. The time corresponding to the mixing process The scale is about 8.6ms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com