A kind of heat-sensitive rubber mixing method

A kind of rubber mixing, heat-sensitive technology, applied in the field of new mixing, can solve the problems of difficult dispersion of compounding agent, difficult temperature control, rapid temperature rise, etc., and achieve the effect of remarkable cooling effect, high production efficiency and high Mooney viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

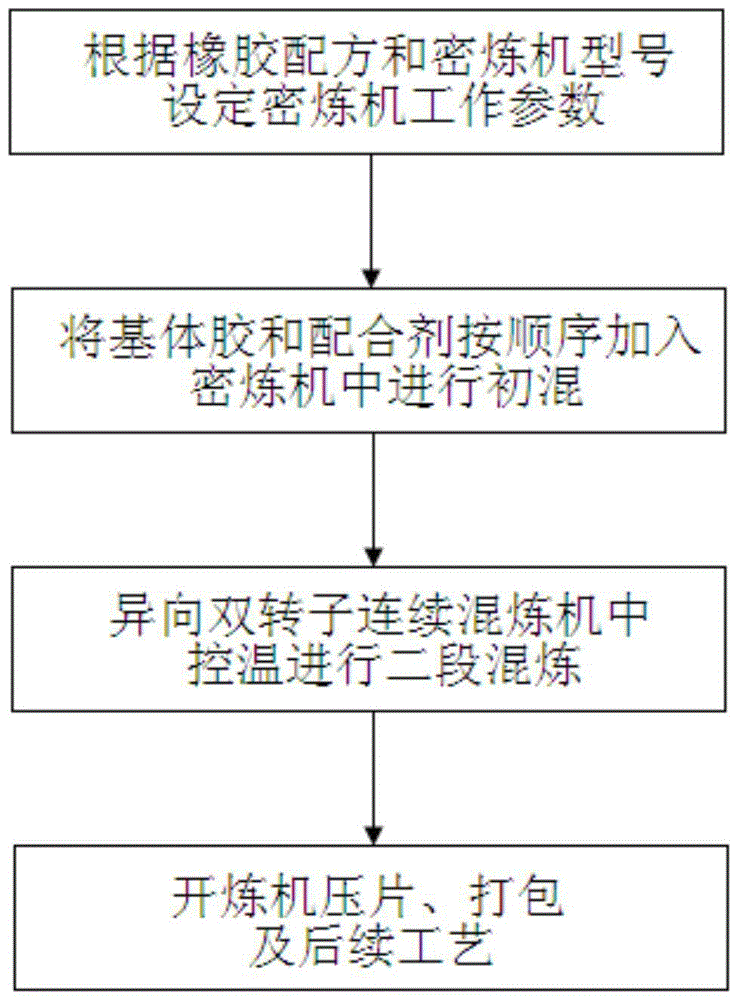

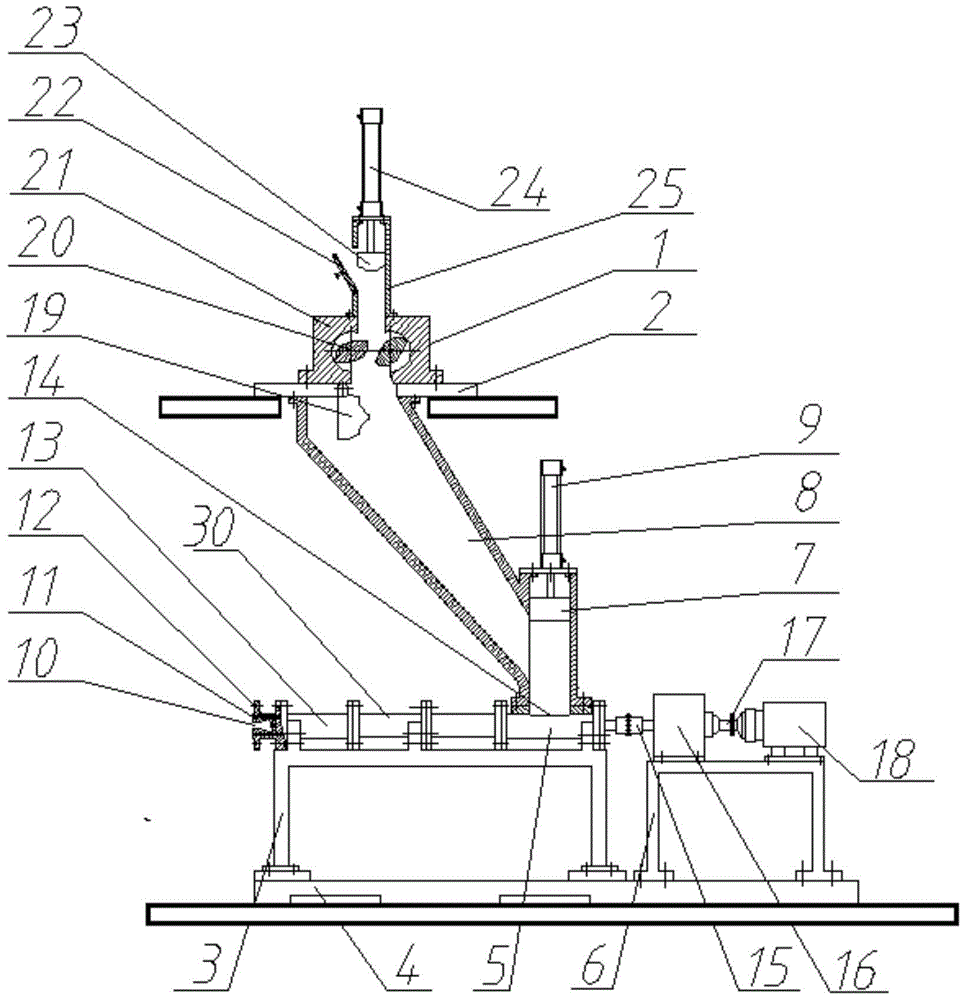

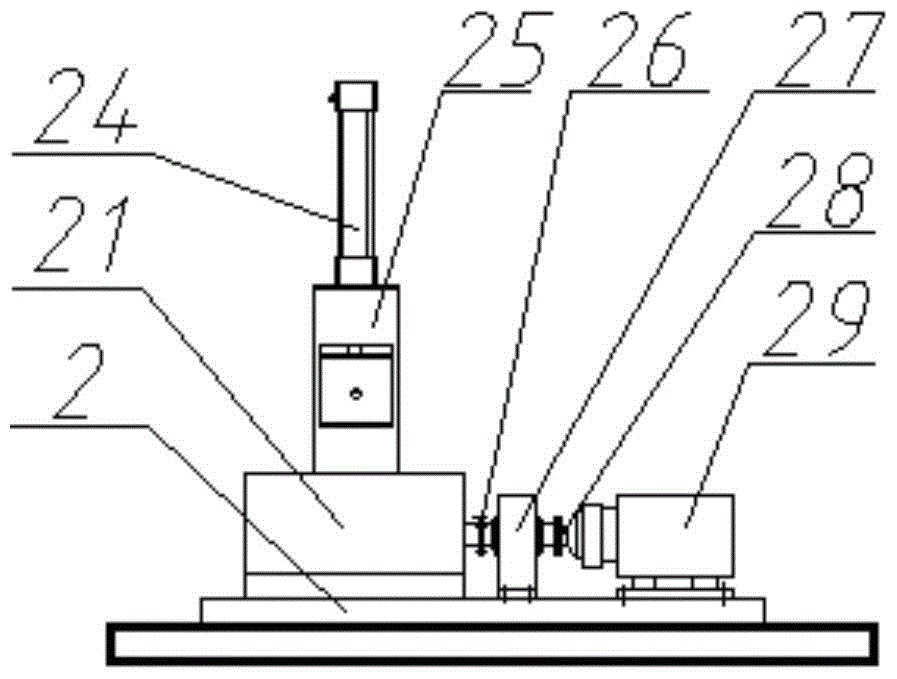

[0018] In this embodiment, a typical heat-sensitive rubber—chloroprene rubber is taken as an example to elaborate, and the process steps of the heat-sensitive rubber mixing method involved are:

[0019] (1) Using a filling factor of 60±3%, based on the specific model of internal mixer 1 and the production formula of neoprene, the mass of various materials is calculated and weighed for later use, and the internal mixing in the initial mixing stage is set The working parameters of machine 1 are: the rotor speed is 45±3r / min, the temperature control is 40±3°C, and the upper bolt pressure is 0.6±0.05MPa; the materials include chloroprene rubber and compounding agent;

[0020] (2) The chloroprene rubber weighed in the step (1) is dropped into internal mixer 1 and carried out the mastication of 30 ± 3s, then add compounding agent respectively and comprise magnesium oxide, plasticizer, ointment, anti-aging agent and 1 / 2 carbon black for mixing, add the remaining 1 / 2 carbon black aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com