Profile induction welding device and method

A technology of induction welding and induction welding, which is applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of low automation of induction welding equipment, low welding efficiency, unstable quality of welded joints, etc., and achieve improved welding and Effects of heat treatment efficiency, equipment investment reduction, and human factor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

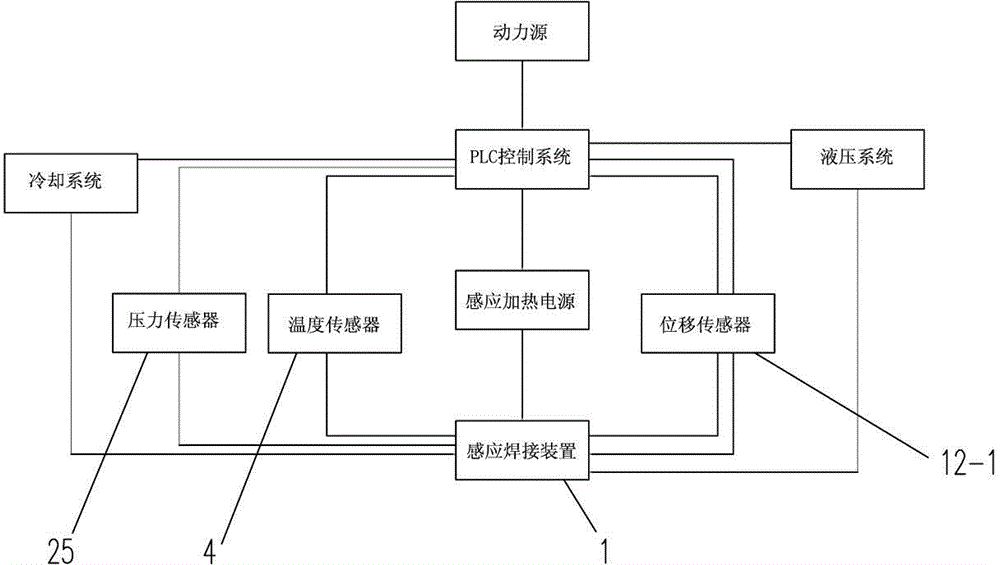

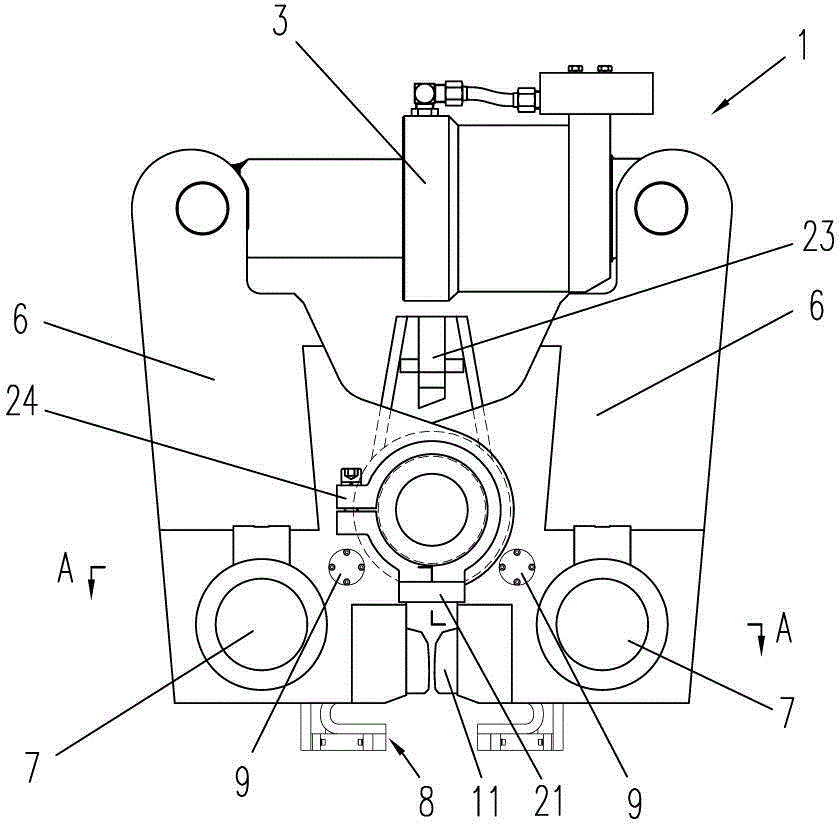

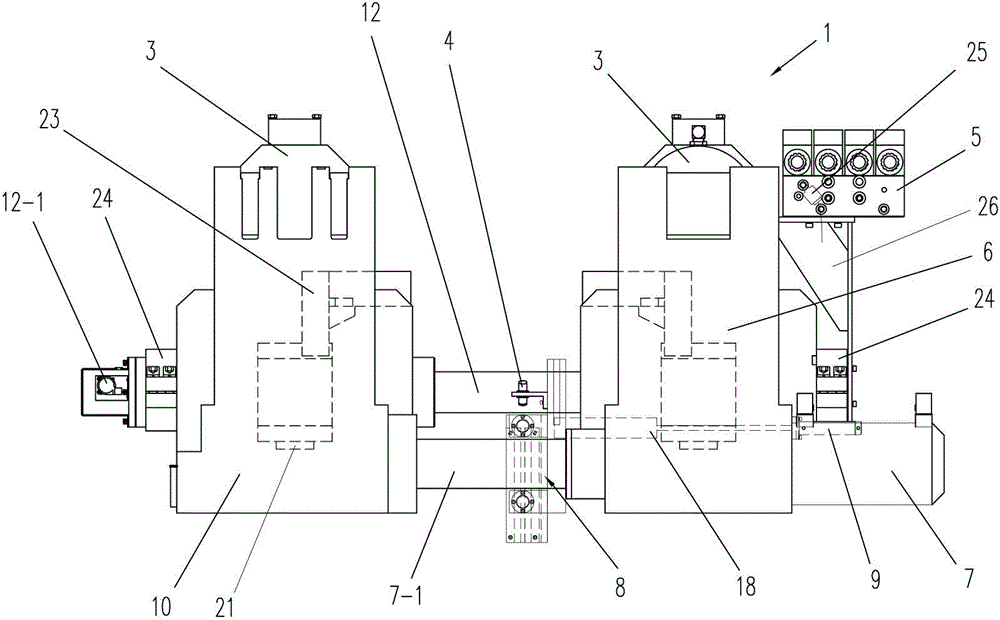

[0039] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, a profile induction welding device of the present invention includes an induction welding device 1, a PLC control system, a hydraulic system, a cooling system and an induction The heating power supply, the induction welding device 1 includes a first set of clamp body 10, a second set of clamp body 6, a central shaft 12, a clamping oil cylinder 3, an upsetting oil cylinder 7 and a jaw 11, wherein the first set of clamp body 10 Together with the second group of clamp bodies 6, they are jointly hinged on the central shaft 12 to form two pairs of pliers-shaped clamping devices. Clamping cylinders 3 are installed between the clamp bodies of each pair of pliers-shaped clamping devices to drive the first set of clamps. The pliers body 10 and the second group of tong bodies 6 rotate around the central axis 12 respectively, and the first group of tong bodies 10 and the second group of tong bodies 6 are all connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com