Preparation method for compound type sole

A compound and method-based technology, which is applied to footwear, other household appliances, household appliances, etc., can solve the problems such as the complicated production process of shoe soles, and achieve the effect of strong bonding, not easy to peel off, and strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

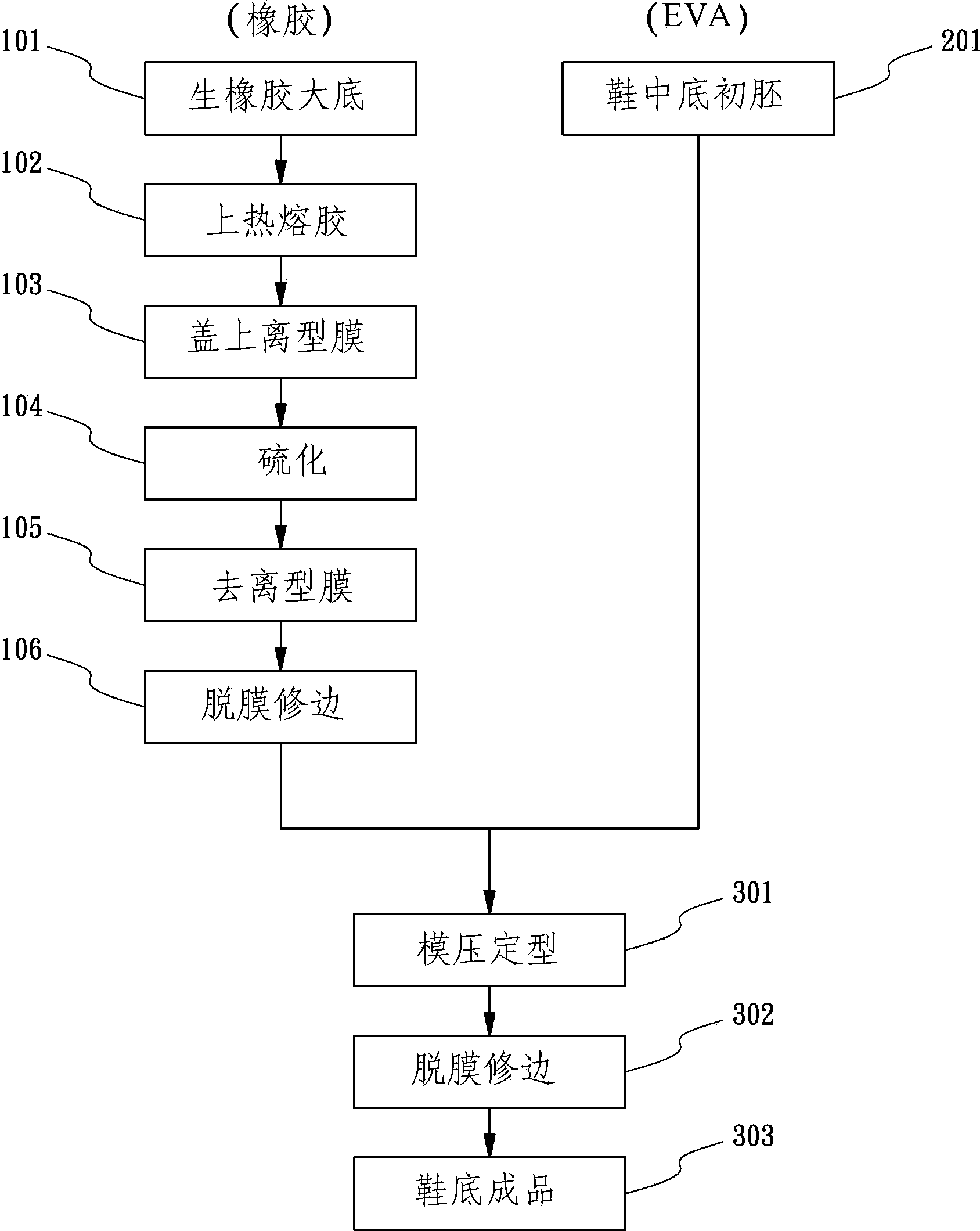

[0029] refer to figure 1 , the preparation method of the composite sole of preferred embodiment of the present invention comprises the following steps:

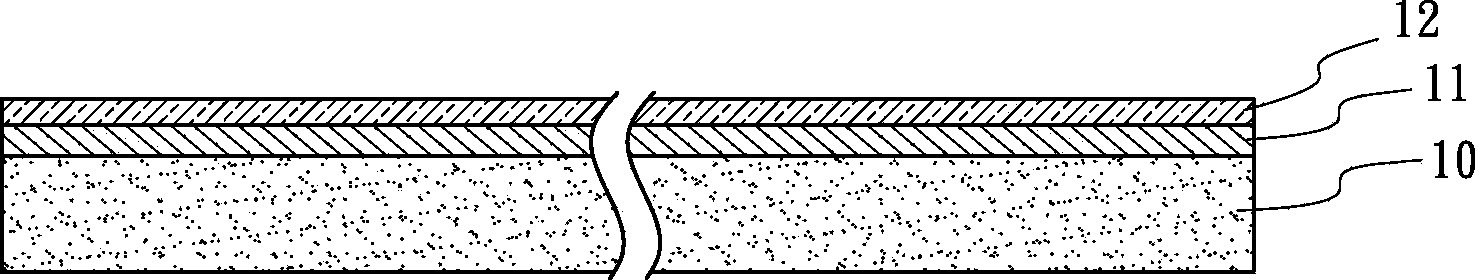

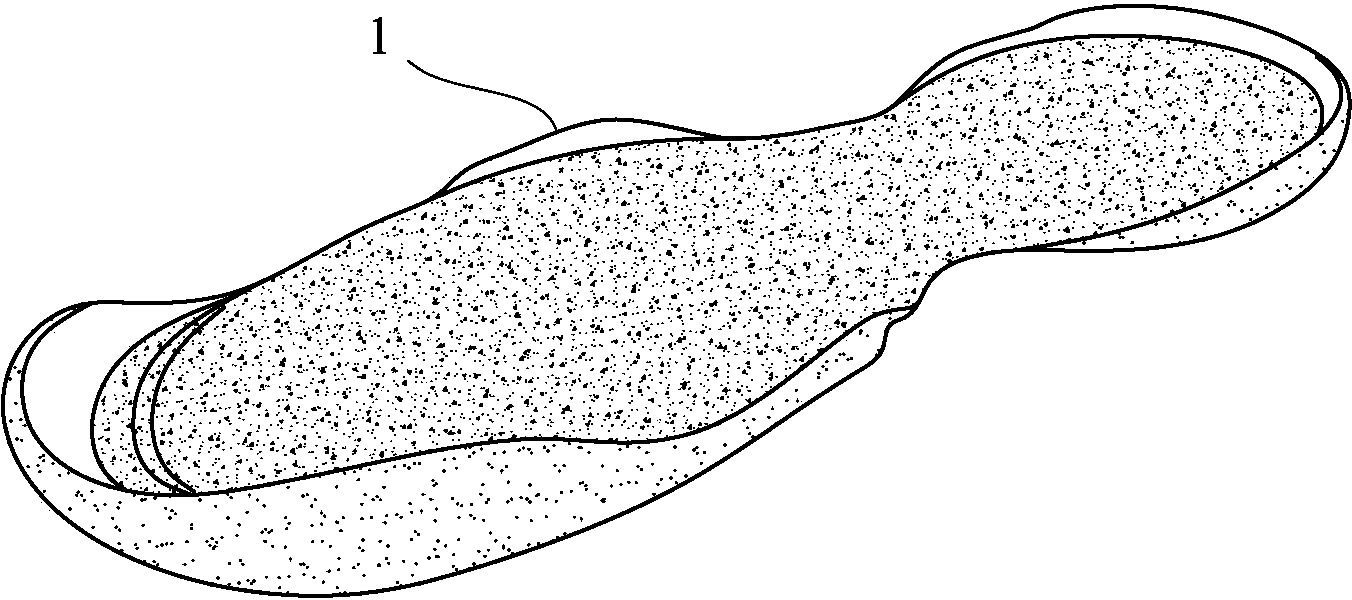

[0030] First, in step 101 to step 107, prepare a shoe outsole 1 coated with hot melt adhesive on the surface, referred to as a rubberized shoe outsole 1, such as image 3 shown. refer to figure 2 According to the cross-sectional view of the structure, the preparation method of the rubberized shoe outsole includes: in step 101, a raw rubber 10 is provided, that is, rubber that has not been vulcanized. Next, in step 102 , a layer of hot melt adhesive 11 is coated on the raw rubber 10 . Since the raw rubber 10 itself has a rough surface, the adhesive force between it and the hot melt adhesive 11 can be increased. In step 103 , a release film 12 is covered on the rubber surface of the raw rubber 10 coated with the hot melt adhesive 11 . Next, in step 104, the aforementioned raw rubber 10 coated with hot melt adhesive and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com