Hybrid powertrain with centrifugally actuated electric motor disconnect clutch and control method

A technology for hybrid vehicles and clutches, applied in the direction of automatic clutches, hybrid vehicles, clutches, etc., can solve problems such as restrictions, and achieve the effects of eliminating needs, reducing rotation losses, and eliminating power requirements and rotation losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

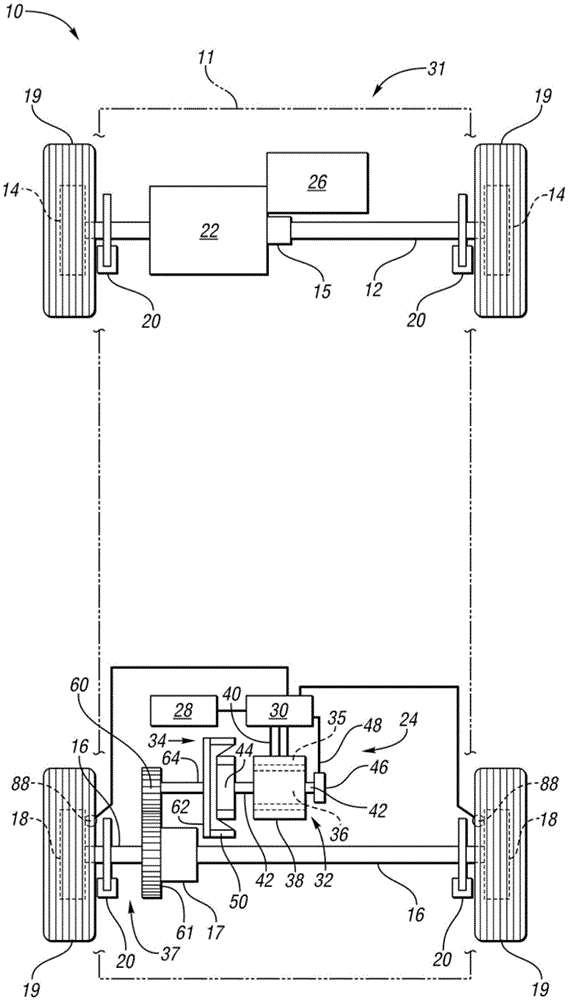

[0009] Referring to the drawings, wherein like reference numerals represent like parts throughout the several views, figure 1 A hybrid electric vehicle 10 is schematically shown having a frame 11 (shown in phantom) having a first axle 12 connected to a first pair of wheels 14 and a second axle connected to a second pair of wheels 18 16. In one embodiment, wheels 14 are front wheels and wheels 18 are rear wheels. exist figure 1 In , wheels 14 , 18 are shown attached to tires 19 . Each axle 12, 16 has two separate axle sections connected via a respective differential 15, 17, as known to those skilled in the art. Each wheel 14, 18 has a friction braking mechanism 20, shown as a disc brake. The first axle can be connected to a transmission 22 and the second axle 16 can be connected to an electric drive module 24 . The transmission 22 may be an automatic transmission and may or may not include an electric motor / generator such that the transmission 22 may or may not be a hybrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com