Mining dump truck gantry beam and mining dump truck frame

A technology for mining dump trucks and bottom beams, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve problems such as unfavorable longitudinal beam hoisting, unfavorable processing, and difficulty in operation, and achieves convenient assembly process, saving processing costs, Good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

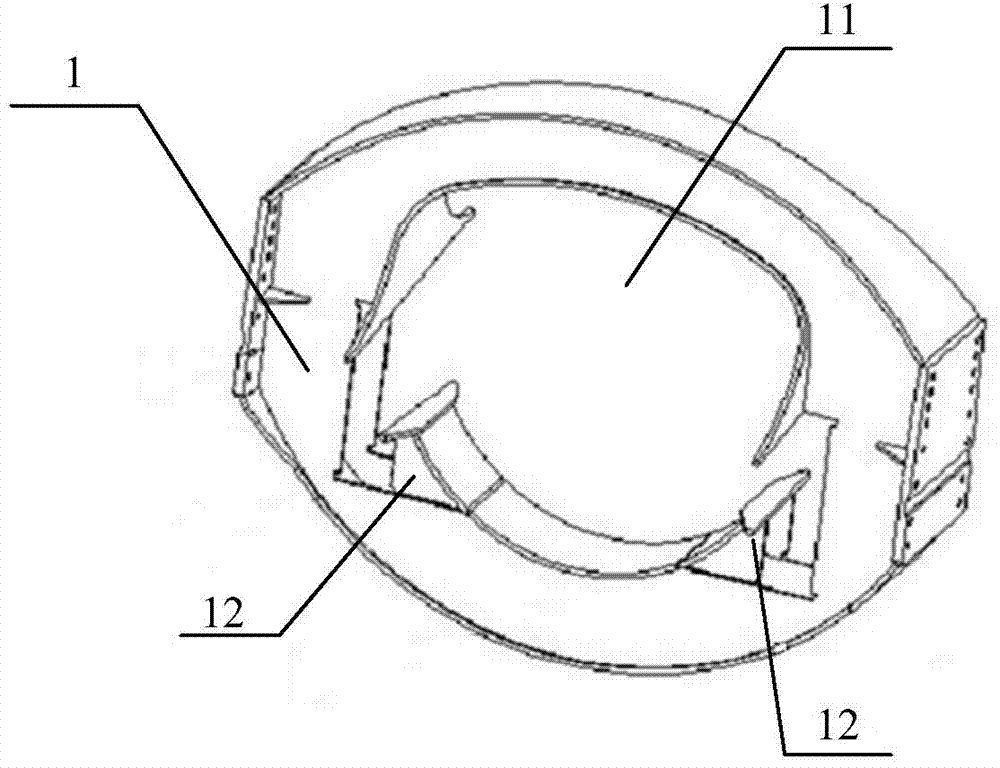

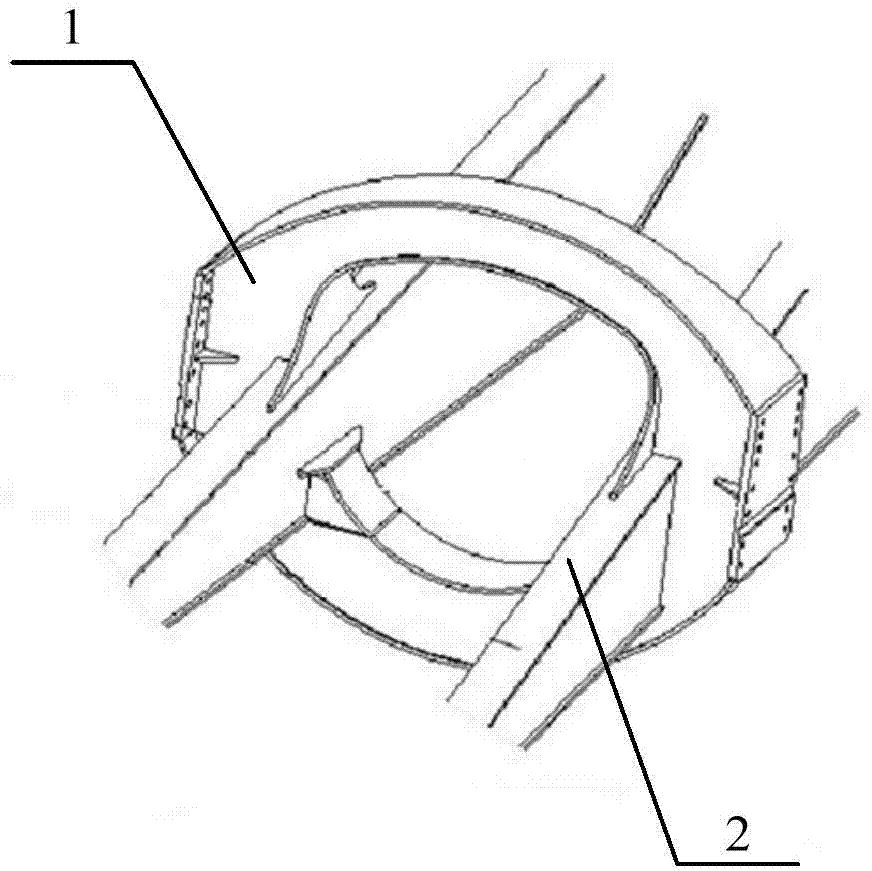

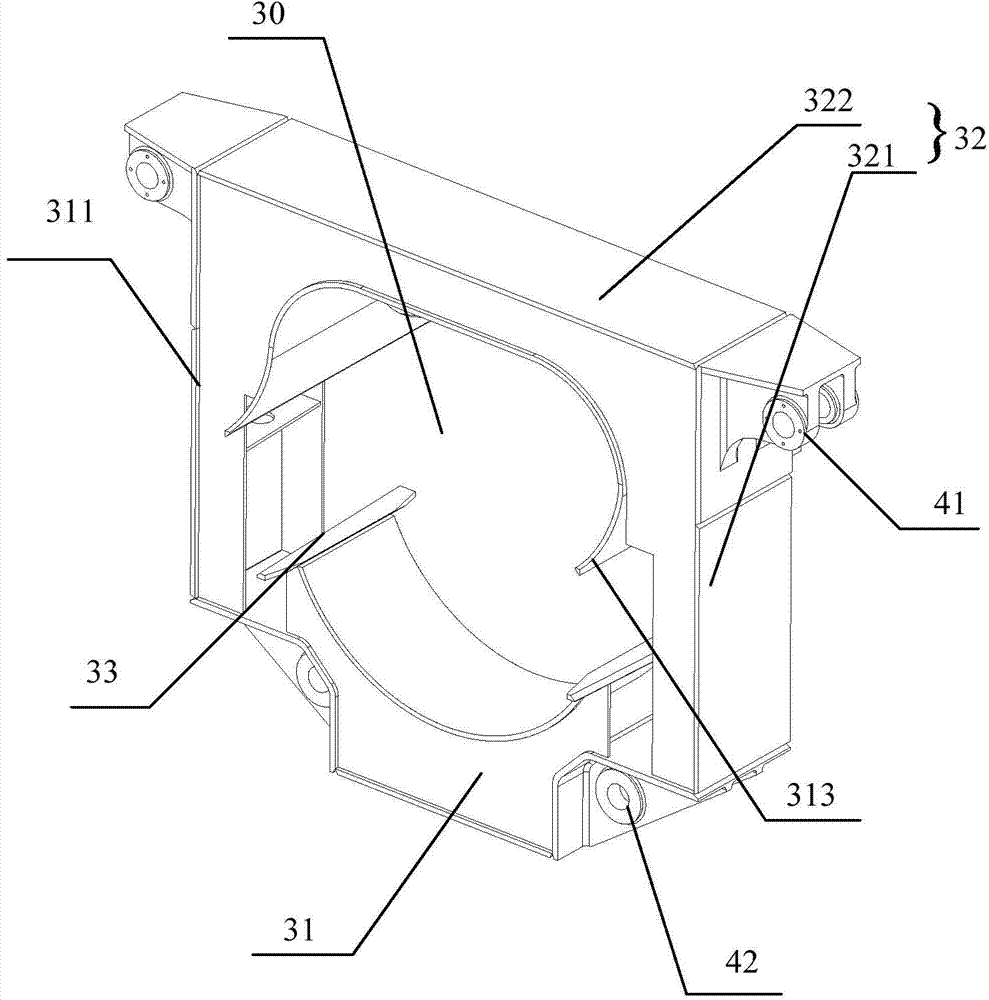

[0015] image 3 It is a perspective view of an embodiment of a gantry beam of a mining dump truck of the present invention; Figure 4 for image 3 Schematic diagram of the midsole beam structure; Figure 5 for image 3 Schematic diagram of the structure of the roof beam; please refer to Figure 3-5 , the present embodiment provides a mining dump truck gantry beam, including a bottom beam 31, a top beam 32 is buckled on the bottom beam 31, and the top beam 32 includes two support legs 321, and the two support legs 321 are respectively supported on the bottom beam 31 On the top surface 310, the top beam 32 and the bottom beam 31 encircle a through hole 30; on the top surface of the bottom beam 31 and inside the two supporting legs 321, two protrusions 33 are respectively formed, and the two protrusions Between the portions 33 and the corresponding supporting legs 321 , gaps are formed for the longitudinal beams to pass through.

[0016] Specifically, the bottom beam 31 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com