Oxidation ditch system

An oxidation ditch and secondary sedimentation tank technology, applied in aerobic process treatment, sustainable biological treatment and other directions, can solve the problem of less research on the operating parameters of biological selectors, achieve good sedimentation performance, inhibit sludge bulking, inhibit The effect of occurrence and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

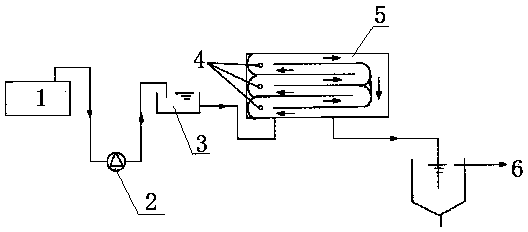

[0009] The oxidation ditch system consists of a water storage tank 1, a peristaltic pump 2, a biological selector 3, an oxidation ditch 5 and a secondary sedimentation tank 6 which are connected in sequence. A surface aerator 6 is provided in the oxidation ditch 5 .

[0010] The biological selector 3 is made of PVC plastic plate, with a total effective volume of 23.33 L, divided into 6 grids, each grid is 3.89 L; the main reactor is made of stainless steel, the effective volume of the oxidation ditch 5 is 240 L, and the effective volume of the secondary sedimentation tank 6 is The capacity is 100 L. The bioselector 3 is stirred by a small submersible pump, and the reaction conditions are varied between anoxic and anaerobic. Oxidation ditch 5 uses surface aerator 4 for aeration, and aerator 4 realizes the process of aeration and pushing flow in the ditch (the aerator at the water inlet mainly plays the role of aeration, and the last two aerators mainly play the role of pushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com