Micro model wettability accuracy control technology

A wettability and microscopic technology, which is applied in the field of petroleum exploration and development in oil fields, can solve the problems of wettability change, poor model wettability stability, and low control precision of microscopic model wettability, and achieve good stability and wettability. Controlling the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

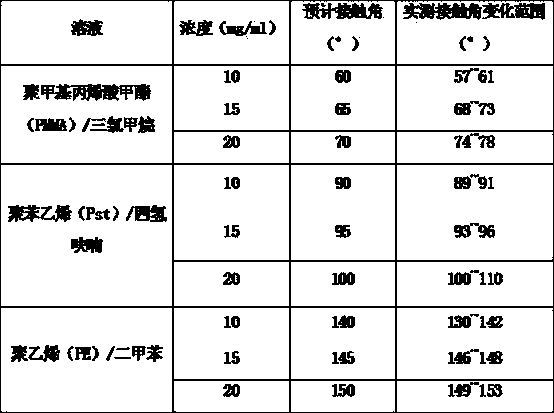

[0022] A microscopic glass model wettability control agent, wherein the microscopic glass model wettability control agent is polymethyl methacrylate, polystyrene and polyethylene. Polymethyl methacrylate is a white powder particle, which is used for models whose contact angle is less than 90°; polystyrene is a white transparent particle, which is used for models whose contact angle is between 90°-140°; polyethylene is a white opaque particle , for models with contact angles greater than 140°.

[0023] Microscopic glass model wettability control method:

[0024] 1) Put the slides to be tested in 10% sodium hydroxide solution and heat for 1 hour to remove surface organic impurities, then bake in a special oven at 70°C for 2-4 hours

[0025] 2) Wash the used beakers, Erlenmeyer flasks and other glass instruments with clean water and then with distilled water, and put them in a special oven at 70°C for 2-4 hours.

[0026] 3) Accurately weigh 2g, 3g, and 4g of polymethyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com